- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

What is Fatigue Testing?

Fatigue testing consists of applying a cyclic load to a test specimen to determine performance data during situations similar to real world working conditions.

ATS’s experienced engineers can help design test programs and fabricate the required fixturing for all types of fatigue testing from standard ASTM methods to fully custom cyclic tests. ATS also performs life cycle testing for numerous industries ranging from medical to consumer products. Give us a call for your most challenging projects and our highly skilled engineers will develop a custom solution for your needs.

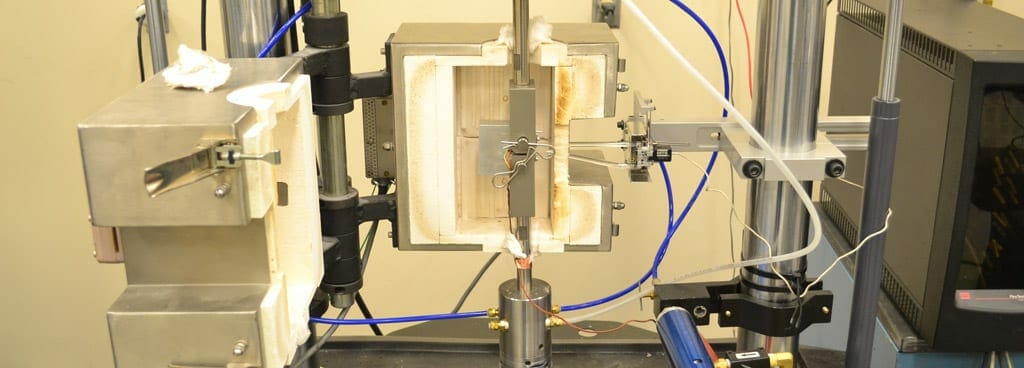

ATS has expanded our testing capabilities to include fatigue, fracture toughness, CTOD, and high temperature tensile testing with several MTS Fatigue Testers. The versatile servo-hydraulic systems will allow us to perform numerous types of fatigue tests on many different sample sizes and orientations. Some of our wide range of testing parameters are listed below.

Machine Capabilities:

- Temperature Range: Ambient to 1000°C

- Load Capacity: 2 lbs to 55 Kip

Fracture Toughness

Fracture Toughness testing determines the amount of stress required to propagate an existing flaw or defect in specific materials. Since traditional methods of destructive testing cannot always predict how a material will behave with a defect, fracture toughness is very important in the design stage.

Crack-Tip Opening Displacement (CTOD) is used as a type of fracture toughness testing to determine if a material is appropriate for strenuous working conditions. CTOD testing is the measure of plastic deformation at the crack tip during stable tearing or at a significant event such as a “pop in” prior to failure in a pre-cracked sample. This type of test is used for materials with high toughness that do not produce a valid Kic using ASTM E399. It is often used to determine the variation of toughness in the base metal, heat affected zone, and weld material of welded plate or pipe.

ASTM Specification Capabilities:

- ASTM E466 — Fatigue Testing of Metallic Materials

- ASTM E399 — Linear-Elastic Plane-Strain Fracture Toughness (KIC) of Metallic Materials

- ASTM E1290 — Crack-Tip Opening Displacement (CTOD) Fracture Toughness Measurement

- ASTM E606 — Strain-Controlled Fatigue Testing

- ASTM E1820 — Measurement of Fracture Toughness (JIC-CTOD Measurement)

Request Form

"*" indicates required fields