- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

The Karl Fischer Testing Method of Moisture Detection

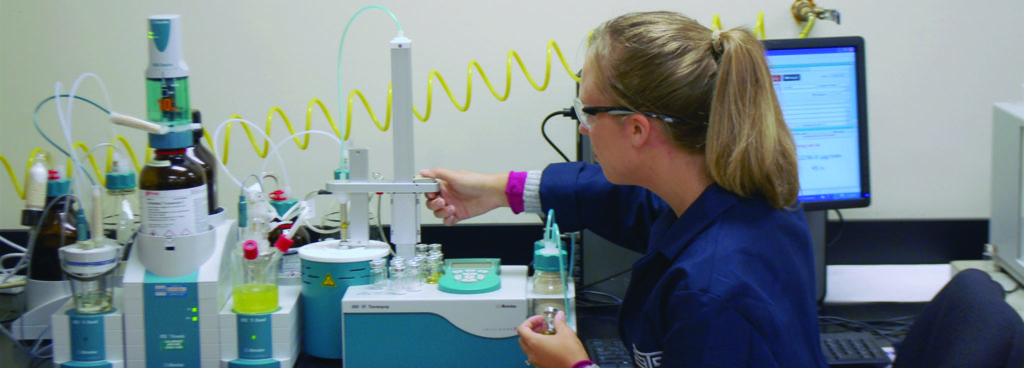

Applied Technical Services performs Karl Fischer testing to determine the moisture content of sample materials. We maintain a state of the art Karl Fischer unit capable of volumetric and coulometric titration, which offers a detection limit of 5ppm ±5 µg. Our system also utilizes a specialized oven attachment that allows analysis of moisture in solid samples by vaporization of the moisture. Our Karl Fischer unit is able to provide moisture measurements in terms of % moisture, parts per million (PPM), and micrograms (µg) of water.

Karl Fischer (KF) Titration is a technique for the determination of moisture content. It is a process based on the reaction of iodine with water. The KF method is one of the few techniques that will measure water content and not be affected by other volatiles. With our KF titration unit both free, and bound water can be determined, for example surface water on crystals or the water contained inside them. The method works over a wide concentration range from 5 ppm up to 100%, and supplies reproducible and accurate results. Our unit can effectively test numerous types of solid or liquid samples. Sample size can vary and is typically between 0.5-5 grams depending on the water content within the sample. There are two methods used to perform Karl Fischer testing, volumetric and coulometric.

Volumetric Titration Method

Volumetric titration is used for moisture content above the 1-2% range. In this method samples are injected directly into an air tight titration cell containing a solvent, and dissolved before the titration begins. Through the use of an automatic buret, reagent is added and reacts with the water to return the conductivity to the starting point. The amount of water/moisture in the sample is calculated based on the amount of reagent need to reach this point. It has a range of moisture content from 100 parts per million to 100%.

Coulometric Titration Method

For coulometric titration the reagent and solvent are combined in the titration cell. When a sample is introduced into the titration cell and dissolved, reagent is released by the induction of an electrical current. The moisture is determined by the amount of current required to consume the water. The advantage of the coulometric KF method is the capability to accurately measure small amounts of moisture. Sensitivity of our instrument is as low as 0.1 micro-gram (µg) of water. This method is normally used for moisture content below 1 % or for samples where the amount of moisture is less than 200 micrograms.

Moisture Analysis

The addition of a specialized oven allows analysis of moisture in solid samples, or unique liquid samples by vaporization of the moisture. For a sample to work by direct injection, it needs to be dissolvable in a solvent compatible with the KF Reagents. Substances that release their water slowly or at high temperatures (e.g., plastics or inorganic salts) are not suitable for a direct Karl Fischer titration. For these samples we are able to determine moisture using the oven attachment.

The sample is weighed into its own sample vial and hermetically sealed, which minimizes contamination and carry over effects. Using PTFE-covered septa prevents any moisture uptake from ambient air. The vial is placed in the oven chamber and heated, a carrier gas transfers the released water to the titration cell, where it is then determined by KF titration. Depending on the sample’s water content, the subsequent KF water determination can be carried out volumetrically or, for trace amounts, coulometrically. Since only the water enters the KF cell and the sample itself does not come into contact with the KF reagent, unwanted side reactions and matrix effects are eliminated. You can determine the water content of solids (powders or granules), liquids of different viscosities, plus pastes and fats.

These methods are widely used in the areas of transformer oil monitoring, crude and lube oil analysis, polymer analysis, and many applications in the solvent, pharmaceutical and chemical industries.

Typical Areas of Application of Karl Fischer Testing

- Petrochemicals, including fuels, oils, crudes, hydraulic fluids and lubricants

- Polymers, including pellets, polymer/solvent mixtures, raw materials and precursors

- Pharmaceuticals, including powders, liquids, tablets/pills and lyophilized samples

- Cosmetics, including makeup, soaps, and toothpastes

- Chemical Applications, including solvents, salts, organic matter, and metals

- Foods, including liquids, formula, mixes, and others

Commonly Analyzed Samples

Solvents | Finished Products | Industrial Products |

|---|---|---|

Acetic Acid

| Aftershave lotion

| Freon

|

Acetonitrile

| Almond Oil

| Gasoline

|

Benzene

| Aperitif

| Insulating Oil

|

Chloroform

| Butter

| Metal oxides

|

Cresols

| Coffee Cream

| Mineral Oil

|

Cyclohexane

| Cognac

| Nitrogen

|

Dioxane

| Cough Syrup

| Petroleum

|

Ethanol

| Epoxy

| Plastic Films

|

Furan

| Baby Formula

| Plastic Granules

|

Glycerol

| Lotion

| Salicylic Acid

|

Chexane

| Margarine

| Salts

|

Isopropanol

| Mascara

| Silicone Oil

|

Liquid Paraffin

| Mustard

| Sulphuric Acid

|

Nitrobenzene

| Paint

| Transformer Oil

|

Octanol

| Sunscreen

| |

Petroleum Ether

| Vinegar

| |

Pyridine

| ||

Tetrahydrofuran

| ||

Toluene

| ||

Vinyl Ether

| ||

Xylene |

Karl Fischer Testing at ATS

ATS’ team of organic chemists are very skilled at understanding the needs of our clients and selecting the equipment and test methods most appropriate to the situation in order to test for suspected or known contaminants. They return accurate findings quickly because of their familiarity with the method — our chemical analysis lab regularly performs Karl Fischer testing on client samples.

Request Form

"*" indicates required fields

Chemical Analysis

- Ash Testing

- Azo Dyes

- Azo Dye Testing

- Benzene Analysis

- Biocompatibility Testing for Medical Devices ISO 10993

- Chemical Composition Testing Lab

- Cleanliness Testing Lab

- Contamination Test

- Combustion Analysis

- CPSIA Testing Lab

- DSC Analysis

- DSC Analysis of Polymers

- DSC Polymer Characterization Analysis

- DSC Testing

- Ethylene Oxide GC MS Analysis

- EPA Method 24 Testing

- Extractables Leachables Testing

- Extractables Testing

- Flame Retardant Chemicals

- Formaldehyde Testing

- FTIR Analysis

- FTIR Chemical Analysis

- FT-IR Material Analysis

- FTIR Surface Analysis

- FTIR Testing

- Gas Chromatography Mass Spectrometer Analysis

- GCMS Analysis and Testing

- GCMS Oil Analysis

- Halide Anion Testing

- HPLC Analysis Services

- ICP-AES Analysis

- ICP-OES Testing

- ION Chromatography Testing

- ISO 10993 Testing

- ISO 10993 Testing Lab

- Karl Fischer Testing

- Leachable Testing

- LECO Testing

- Melting Point Analysis

- Methane Analysis Gas Chromatography

- Methanol Contamination Testing

- OES Materials Testing

- Optical Emission Spectroscopy

- PAH Testing

- Particle Size Distribution Analysis

- Particle Size Distribution Analysis Laboratory

- Particle Size Distribution Testing

- PFOA Testing

- PFOS/PFOA Testing

- Plastic Impact Testing

- Plastic Pipe Testing

- Polymer Characterization Lab

- Polymer Material Testing

- Polymer Testing and Analysis

- Powder Characterization

- Product Formulation

- Solvent Testing Lab

- TGA Analysis

- TGA DSC Analysis Lab

- TGA Moisture Analysis

- TGA Polymer Testing

- Thermal Analysis Services

- UV VIS Testing

- VDA 19.1 Cleanliness Testing Lab

- Ventilator Component Cleanliness Testing