- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

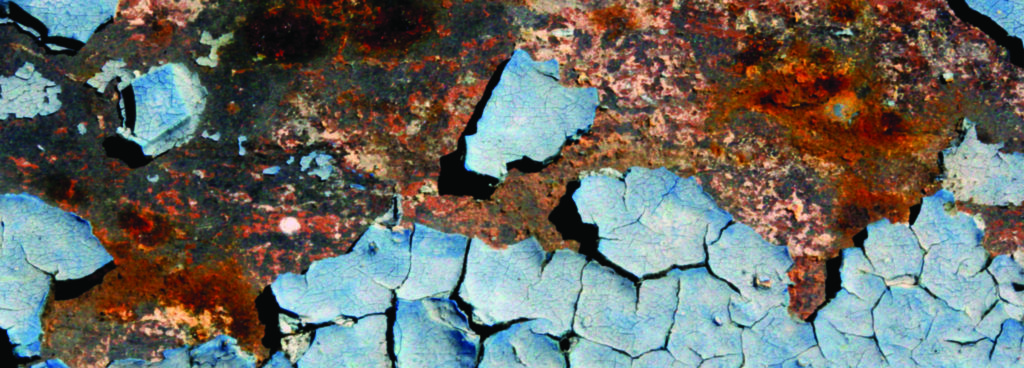

ASTM Coating Adhesion Testing

Coatings must adhere to the substrates they are applied to perform satisfactorily. ATS offers a variety of ASTM coating adhesion testing capabilities to help clients optimize the functionality of their coating applications and avoid premature failure. Our testing services save clients money, providing them with the data necessary to pick the right coating and effectively protect their products, equipment, and infrastructure.

Test Methods:

Pull-off Test — This procedure is accomplished by sticking a loading fixture perpendicularly to the coating, then slowly increasing tensile load until either the fixture and adhesive layers are removed or until a predetermined value is reached.

- ASTM D4541

- ISO 4624

- Quantitative

- Can assess single coat or multi-coat systems

- Can be performed both on-site and in a laboratory

- Performed on a flat surface

Knife Test — This procedure is accomplished by making two cuts into the coating with a utility knife to form an “X” shape. The coating is then lifted at the vertex, using the point of the knife.

- ASTM D6677

- Qualitative

- Evaluated on 0–10 scale

- Based on how difficult coating removal is and size of the removed adhesive

- Highly cohesive coatings may fracture easily and appear to have a low adhesion strength

- Can assess single coat or multi-coat systems

- Can be performed both on-site or in a laboratory

Scrape Test — This procedure is accomplished by loading a rounded stylus or loop onto a balanced beam scrape adhesion tester at a 45-degree angle, then increasing the load until the stylus removes the coating from the surface of the substrate.

- ASTM D2197

- Quantitative

- Tests adhesion of organic coatings like varnish, paint, or lacquer

- Can assess single coat or multi-coat systems

- Can only be performed in a laboratory

- Performed on a flat surface

Tape Test — This procedure is accomplished by cutting either an X shape (method A) or a lattice pattern (method B) into the coating, then applying pressure sensitive over the cuts and removing it.

- ASTM D3359

- ISO 2409

- Also known as Cross-cut Test

- Fast results

- Qualitative

- Evaluated as either pass/fail or on 0–5 scale

- Can be performed using knife instead of tape

- Can assess single coat or multi-coat systems

- ISO 17025 (A2LA Accredited)

ATS and ASTM Coating Adhesion Testing

ATS experts have the resources and the know-how to accurately assess the adhesiveness of client samples using ASTM coating adhesion testing. For over 50 years, we have served numerous industries such as automotive, manufacturing, military, nuclear, and aerospace in the examination and inspection of materials and structures. We take pride in continually improving and provide each client with the highest quality of service.

Request Form

"*" indicates required fields