- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

The Need to CT Scan Parts

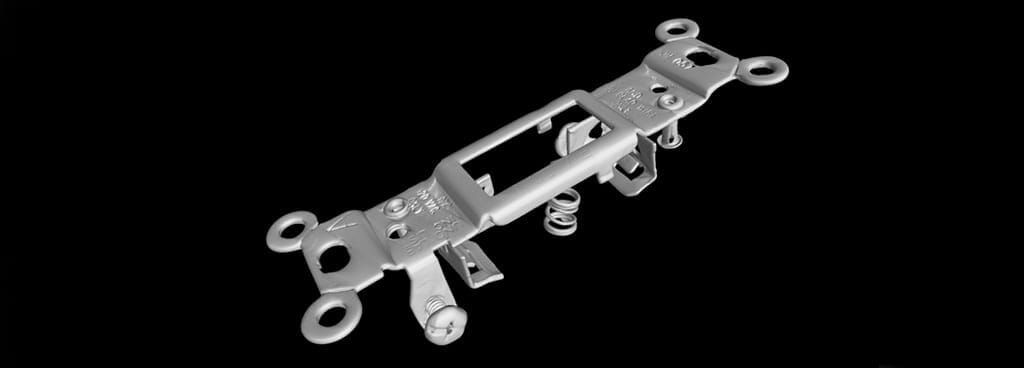

Applied Technical Services’ experienced technicians regularly CT scan parts and assemblies to locate flaws and ensure compliance with design specs. CT scanning, a process more formally known as computed tomography, is a high-resolution testing method with a range of applications. Though the technology was primarily used for medical purposes in the past, testing and analysis companies like ATS now use it as a diagnostic tool in various industrial applications to achieve a detailed, comprehensive, and multi-faceted analysis.

How the Process Works

The process begins when our experienced technician places one of the sample parts inside of our CT chamber. Once they secure the subject inside the chamber and close the doors, the machine produces X-Rays; those X-Rays are focused and released by the projector, typically into a beam, a fan, or a cone pattern depending on the requirements of the test. Next, a mechanical pedestal raises the subject of analysis into the path of the X-Rays, which will penetrate the subject and emerge from the other side. Like in conventional radiography, a detector positioned across from the X-Ray projector captures the rays remaining after it passes through the subject, and generates a black-and-white image based on the data it receives.

The resulting scan, called a tomogram, depicts the inside of the subject as if it had been cleanly sliced into two sections — thus, these images are colloquially referred to as slices. Because more dense materials (e.g., metal) absorb more X-Rays than less dense materials (e.g., air), a tomogram displays the variance between the amount of energy absorbed by parts being scanned, with lighter areas representing areas of greater density and darker areas representing areas of less density. The entire process of taking one slice, from exposure through detection and finally to tomographic reconstruction (the background operation that yields an interpretable image from the raw data the detector receives), takes a matter of minutes due to the processing power afforded by modern computing.

After taking the initial slice, the platform maneuvers to expose a different angle of the subject to X-Rays. This process repeats several hundred times, with the pedestal continually changing the position, rotation, and tilt of the subject between exposures to capture a slice of it from every conceivable angle and orientation. Our technicians can then compile these 2D images to create a type of 3D model called a voxel-based point cloud. This model, essentially a 3D X-Ray, shows both the interior and exterior surfaces of scanned parts with microscopic detail. Furthermore, these experts can generate a CAD model from the data yielded by a CT scan, which helps in a variety of applications.

Applications of CT Scanning

The amount of detail produced by this method allows technicians to analyze a variety of qualities in the parts they scan. ATS’ experience CT scanning parts serves our clients in the following applications:

Clients request first article inspections to verify that their critical parts or final assemblies strictly adhere to their respective design specifications. This process can include assessments of coating characteristics and material properties, but almost every first article inspection will entail a dimensional layout. CT scanning parts helps tremendously in this aspect: our technicians perform volumetric measurements on scanned parts with greater ease than that of a coordinate measuring machine (CMM). It further excels over CMM when analyzing parts with internal components — such as increasingly common additively manufactured parts with complex geometries — because CT does not require a technician to damage the subject in any way to yield accurate internal measurements.

By importing the final file into a metrology software, they can easily measure any of the part’s features by referencing any other point on the model. Performing Part-to-CAD or Part-to-Part comparisons can help easily determine whether the sample parts comply with the tolerances outlined in their design materials. One of CT’s strength in this specific application is that, because technicians take measurements from the CAD model and not from the part itself, ATS can return the sample more quickly than is possible with other methods.

First article inspections can include several types of analysis for which a CT scan will not suffice, including material characterization, coatings analysis, and verification of mechanical properties; ATS performs those other testing methods in-house, and can help with your first article inspection needs regardless of whether they fall under the scope of our computed tomography services.

Companies may require reverse engineering services if they need to update one of their parts’ design model to reflect a last-minute change, or if they need to document the as-is condition of a component that has seen extended service, or even if a legacy component is so old that they do not have a CAD model of it for their files. Whatever their specific need, ATS can help them achieve their goal by performing a thorough dimensional analysis of both internal and external features using computed tomography.

In much the same way as in a first article inspection, CT scanning’s dimensional inspection capabilities make it valuable for reverse engineering. The comprehensive analysis afforded by this method allows clients to determine several characteristics relevant to the subject’s design with a single scan. Furthermore, the non-tactile nature of a CT scan ensures that soft or malleable parts do not warp or deform during analysis, which helps ensure accurate measurements.

Reverse engineering projects may require types of analysis for which CT is not suited, such as metal identification, material toughness characteristics, and determining chemical composition; our labs perform these other methods of analysis, and can thus help you complete your reverse engineering project regardless of whether its scope exceeds the limitations of a CT scan.

Other Applications Include:

Up-to-Date Equipment and Testing Capabilities

ATS’ skilled CT technicians perform all of our computed tomography services. They draw on their collective expertise when using our lab’s powerful equipment to render precise measurements and evaluations for client sample parts. The list below outlines our CT instrumentation:

- Northstar Imaging X5000

- Minifocus 450kV X-ray projector (0.016” Focal spot at 3mA)

- Dual energy capability with 225kV Microfocus X-ray Machine

- Can achieve focal size as low as 0.0002” (based on voltage)

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Resolution of manipulator angle is 0.001°

- Capture elongated subjects unable to fit within a single exposure by scanning with a spiral acquisition

- Zeiss Metrotom 1500, with a 225kV micro-focus

- Annual A2LA calibration

- Certified to accuracy within 4.5 microns

- Chamber fits specimens up to 11.75 in (300mm) in diameter x 23.6 in (600mm) high. 50 kg (110 lb) weight limit.

ATS: A Trusted Computed Tomography Partner

Since 1967, Applied Technical Services has offered testing, inspection, and consulting engineering capabilities of peerless quality. In the 50+ years since our founding, our company has grown exponentially — from a three-person engineering team serving local businesses out of our founder’s basement, ATS is now a multidisciplinary testing firm that employs a group of several hundred technicians, inspectors, chemists, scientists, investigators, calibrators, and Professional Engineers to help clients around the world. The industries that most benefit from our proficiency in CT scanning parts include the following:

- Renewable Energy

- Power Generation

- Nuclear

- Insurance/Legal

- Healthcare/Medical

- Defense/Military

- Conventional Manufacturing

- Automotive

- Aerospace/Aircraft

- Additive Manufacturing

Our Commitment to Quality

ATS’ team of experienced CT technicians perform all of our computed tomography services in compliance with our ISO 9001-certified quality assurance program. We value our customers’ experience and take several steps to ensure they enjoy the best we can provide. The following policies represent some of the measures we have taken along our path to continually improve the quality of our services:

- Our testing personnel quickly return clear, accurate, and detailed reporting

- We guarantee this to ensure our clients can make a timely, educated decision based on our results

- ATS customer service ambassadors receive clients reaching out regarding either the status or results of their testing

- These relationship specialists channel customers to the relevant testing expert and facilitate contact with them

- Technicians and other testing personnel remain accessible to client outreach

- They are responsive to the customer’s needs and remain engaged while helping them secure solutions to their problems

If your company needs a trusted provider to CT scan parts or entire assemblies for a first article inspection, reverse engineering project, or any other application, contact ATS today — We take a closer look!

Request Form

"*" indicates required fields