- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

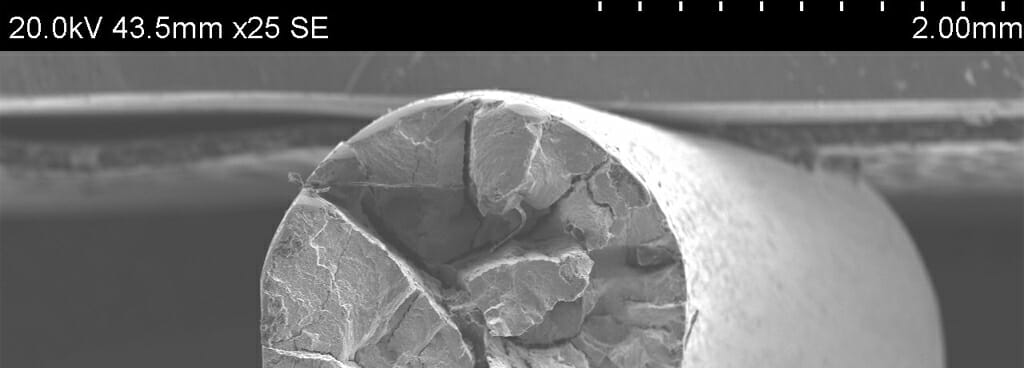

Material Failure Analysis

Applied Technical Services performs material failure analysis to help clients determine the cause behind a case of material failure. Distinct from simply determining the mode of failure of a component, this type of failure analysis approach focuses on how the processing history of base materials and their service conditions contribute to failure. This type of comprehensive evaluation is instrumental in discovering root causes for these failures. Companies know that understanding how and why a material failed in service gives them a basis from which they can address the problem going forward; for this reason, they turn to experienced failure analysis labs like ATS because we help them identify the source behind their material failure and suggest a response to remedy it.

Materials can fail due to a plethora of reasons that will vary based on the service conditions of the final assembly. Experts typically characterize these as brittle, ductile, fatigue, embrittlement, or environmentally related failures. Common causes of material failure include:

- Incorrect Material Selection

- Inappropriate Heat Treat Condition

- Corrosive Attack

- Buckling Load

- Creep (Stress Rupture)

- Thermal Shock

- Fouling (Scale / Deposit Buildup)

- Impact Load

- Fatigue (Mechanical or Thermal)

- Wear

- Mechanical Overload

Our Testing Capabilities

Our failure analysis lab performs a variety of methods to examine material failure modes and find their root causes. Some of the most common techniques that we use for material failure analysis include:

- Nondestructive Testing

- Macrohardness Testing

- Microhardness Testing

- Impact Testing

*ISO 17025 accreditation through the A2LA where noted — ask us about our scope of standards!

Our labs regularly perform the above methods to their most relevant, internationally recognized testing standards. Furthermore, we conduct all material failure analyses to ASTM E2332 to ensure the quality of our investigation. ATS’ failure analysis technicians are thoroughly experienced in determining failure modes and root causes for a variety of materials, including aluminum, cast irons, ceramics, copper alloys, glass, plastics, stainless steel, steel, superalloys, and titanium.

About ATS

Applied Technical Services constantly pursues new levels of excellence as a testing, consulting engineering, and inspections provider. During the 50+ intervening years since our founding in 1967, our company has evolved tremendously; although we began as a cadre of three engineers working with local businesses out of the founder’s basement, ATS now encompasses a multidisciplinary firm that answers the needs of clients around the globe through the expertise of over 1,000 technicians, inspectors, Professional Engineers, chemists, scientists, investigators, trainers, and calibrators. Every industry can greatly benefit from adept material failure analysis services, including the following list that we regularly serve:

- Construction

- Aerospace / Aviation

- Consumer Products

- Power Generation

- Insurance / Legal

- Manufacturing

- Commercial Properties

- Automotive

- Communications

- Chemical

- Pulp & Paper

- Defense / Military

- Nuclear

- Healthcare / Medical

- Oil / Gas

Our Commitment to Quality

One of the guiding principles we have adopted at ATS is providing top quality service in a consistent manner. To ensure that we live up to our goals, we hold ourselves accountable by maintaining ISO 9001 registration. Having this certification distinguishes our quality management system as one that has undergone a rigorous auditing process by ISO-approved inspectors, and has been found to comply with the internationally observed standard outlining good quality assurance practices. We have maintained this certification uninterrupted since 1998. We closely abide by the guidelines set in the ISO 9001 standard because they help lay the groundwork from which we continually work to improve the quality of our services.

To provide the best customer experience possible, ATS upholds the following policies:

- Our testing personnel return clear, accurate, and detailed results in a short turnaround time

- When clients reach out for clarification on the status or results of their testing, ATS customer service ambassadors facilitate contact with the most appropriate staff member

- Testing specialists remain accessible to customers with questions, responsive to their needs, respectful of their time, and engaged while helping to resolve their problem

If your company needs the expertise of a respected material failure analysis provider, contact ATS today for a free quote — We take a closer look!

Request Form

"*" indicates required fields