- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

The Need for Compression Set Testing

Applied Technical Services performs compression set testing on client rubber samples to determine how well they revert to their original shape after prolonged exposure to a compressive stress. Rubber is a valued class of design material due to several characteristics, especially its elasticity. As opposed to plasticity, which indicates a permanent change, elasticity is the tendency of a material to resume its original shape after deforming while undergoing stress. Certain elements affect how well a material returns to its original form, including temperature, chemical exposure, and duration of deformation.

Certain service environments may require a rubber component to undergo repeated or even constant compression, such as in the case of O-ring seals, gaskets, and automotive tires. Ensuring these components perform as required for their intended purpose reduces the likelihood that the final assembly will prematurely fail. Manufacturers send their rubber samples to a third-party testing lab, such as ATS, to validate their components’ design and material properties before production or placement in specific service environments.

How the Method Works

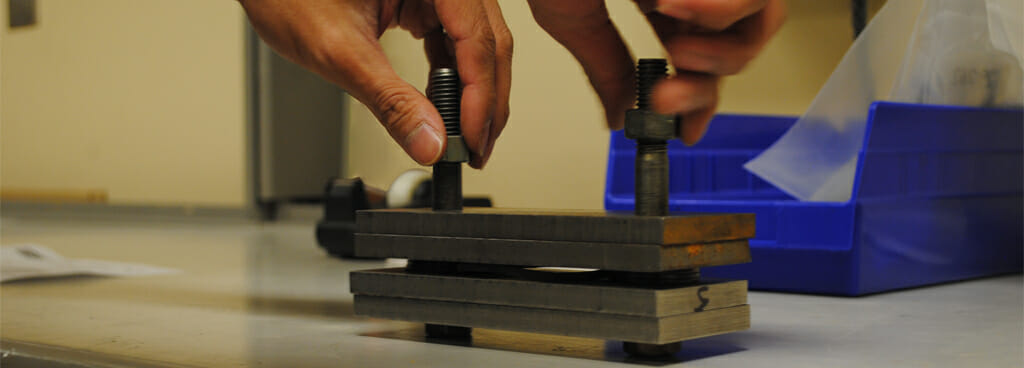

ATS’ polymer testing technicians use a standardized compression device to perform this method. They first measure the initial height of the rubber compound sample to establish a baseline. Next, they install the sample between two plates secured to one another by bolts and nuts. Tightening the nuts draws the plates together, compressing the sample between them to a certain deflection determined by spacers. After time has elapsed, the duration of which is determined by testing specifications or the client’s direction, technicians loosen the nuts holding the sample in place and remove it from the fixture. Checking the final height allows them to calculate the compression set, a numerical value expressed as a percentage of the original thickness, indicating the amount that the sample has permanently deformed. Furthermore, we can induce hot and cold climates to account for how varying temperatures affect the material’s performance.

Our polymer testing lab regularly performs compression set testing to the following internationally recognized standards:

- ASTM D395 Method A & B

- ISO 815

- ASTM D1229

- ISO 1653

- ASTM D3574

- ASTM D3575

- ASTM D1667

- JASO M305 Method A & B

- ASTM D1414 Method B

- BS EN 604

- BS ISO 7743

About ATS

Applied Technical Services offers testing, consulting engineering, and inspection capabilities to clients from around the world. Established in 1967 by a group of three engineers serving local businesses from the founder’s basement, ATS has grown immensely over our 50+ years in business. We now comprise a multidisciplinary services firm employing over 1,000 technicians, chemists, scientists, calibrators, trainers, investigators, inspectors, and Professional Engineers to answer the varied needs of clients from a wide range of industries. Of the many we serve, manufacturing clients are the ones who benefit the most from our expertise as a compression set testing provider.

Quality is Our Priority

Our technicians perform all polymer testing services in accordance with our quality assurance program. The Marietta location, where all such testing occurs, is registered to ISO 9001. This distinction means that ISO-approved auditors assessed our business processes and affirm that they align with the principles set down in the internationally recognized standard on effective quality management systems. ATS has maintained our ISO 9001 certified status uninterrupted since achieving it in 1998 because we prioritize quality as one of our core values and want our clients to know it. Closely abiding by the guidelines established in this standard builds a foundation of excellence from which we continually improve the quality of our services.

ATS upholds the following policies to ensure we provide the best customer experience possible:

- Our testing specialists produce clear, accurate, and detailed reporting

- They return these results within a quick turnaround window to empower clients to make timely, informed decisions regarding the results of their testing

- Our customer service representatives act as ambassadors for clients reaching out with questions about the status or results of their testing

- These client relationship experts facilitate contact with the most relevant staff member

- Our lab personnel are accessible to clients reaching out for clarification

- They remain responsive to customer needs and engaged in helping find a solution to their problems

If your company needs compression set testing to verify the durability and elasticity of a rubber sample, contact ATS today for a free quote — We take a closer look!

Request Form

"*" indicates required fields

Complete List Of Metallurgy Links

- 3D Inspections

- 3D Part Inspection

- 3D Scanning Services

- 3D X-Ray Imaging

- 3D X-Ray Services

- Computed Tomography

- Computed Tomography Lab

- Computed Tomography Metallurgy

- Computed Tomography Scanning

- Computed Tomography (CT) Services

- CT 3D Scanning for Reverse Engineering

- CT Inspections

- CT Lab

- CT Metrology

- CT Scan Companies

- CT Scan Parts

- CT Services

- First Article CT Scanning

- X-Ray Microtomography

General Services

- EDS Chemical Analysis

- Litigation Support

- Material Identification

- Metallography Lab

- SEM Lab

- Metallurgical Services

- Nondestructive Hardness Testing

- Porosity Analysis

- PPE Testing

- Reverse Engineering Services

- Scanning Electron Microscopy

- Scanning Electron Microscope Services

- Tensile Testing Metallurgical Lab

Metals Testing and Metallography

- Brinell Hardness Tests

- Case Depth Hardness

- Case Depth Testing

- Fracture Analysis

- Fracture Surface Analysis

- Grain Size Analysis

- Grain Size Distribution

- Hardness Testing Labs

- Hardness Testing Services

- Intergranular Corrosion Tests

- Knoop Hardness Testing

- Laser Grain Size Analysis

- Metal Tests

- Metal Fracture Analysis

- Metallurgical Testing Services

- Metallography Lab

- Metallography Microstructure and Analysis

- Rockwell Hardness Tests

- Superficial Rockwell Hardness Tests

- Vickers Hardness Test