Additive manufacturing technologies have a versatile range of applications. Metallurgy provides an equally diverse range of testing methods for assessing material quality. At Applied Technical Services, our metallurgists and engineers help clients determine the most effective testing method for analyzing their products. We can examine additively manufactured products in numerous aspects, giving clients a comprehensive understanding of their products’ material structure and integrity.

Microstructure Analysis

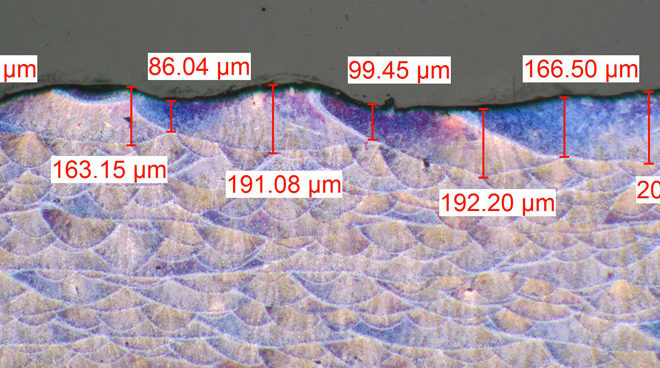

Our metallurgy lab can assess the microstructure of polymers, alloys, and ceramics, following the standards such as ASTM E3. We can assess and measure qualities such as melt pool depth by using microscopic measuring techniques per several ASTM/ISO procedures. We evaluate the different microstructures in as-printed, hot isostatic pressing (HIP) processed, and heat-treated samples. Our analysis processes also help with inclusion identification. We perform energy-dispersive spectroscopy (EDS) for semi-quantitative phase and inclusion analysis according to ASTM E1508. Our assessments also address:

- Grain Size/Flow/Orientation/Structure

- Phase Identification

- Intergranular Corrosion

- Presence of Nitriding

- Case Depth

- Coating Thickness

- Intermetallic Phases

- Porosity

- Void Orientation

Image Analysis

ATS performs image analysis for additive manufacturing samples according to standards such as ASTM E1245. We use a 4K ultra-high accuracy Keyence VHX-7000 digital microscope to evaluate surface and core porosity, yielding an area percentage, average diameter, min and max size, and other measurements. Image analysis also assists with phase evaluation.

Fractography

Our fractography capabilities include optical and scanning electron microscopy (SEM) services. These metallurgical tests cover initiation identification, crack propagation analysis, and fracture mode assessment.

Additional Analysis Techniques

We provide several services in conjunction with our metallurgical analyses for additive manufacturing, including:

- Density analysis per ASTM B962 and B311

- Rockwell hardness testing per ASTM E18

- Micro-indentation hardness per ASTM E92 and ASTM E384

We also provide SEM/EDS services. SEM/EDS testing provides information on surface finish and raw material morphology, as well as phase and inclusion identification per ASTM E1508.

ATS: Experts in Metallurgy

Applied Technical Services (ATS) has decades of experience in metallurgy. Our experts work with additive manufacturing clients to determine the full scope of each project, addressing any factors that would influence the testing decisions. ATS delivers clear, detailed, and accurate reporting within a short time frame.

Contact ATS today for more information on how our metallurgy laboratory can benefit the additive manufacturing industry.