- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Fatigue Testing Lab

Applied Technical Services’ Family of Companies provides a state-of-the-art fatigue testing lab for manufacturers needing to evaluate the structural integrity and resilience of their products, including medical devices.

Issues With Fatigue

Fatigue is categorized by the initiation and growth of cracks resulting in a catastrophic fracture in a material or product. It can prove problematic to the quality, safety, and performance of materials and products. Testing for fatigue is essential in investigating, analyzing, and preventing fatigue.

Fatigue Testing

Fatigue testing is a specific area of mechanical testing that can determine the material’s ability to withstand cyclic loading conditions. This testing method helps experts evaluate the material’s lifespan under certain conditions. This method of mechanical testing helps assess the material’s fatigue strength and crack resistance.

How Fatigue Testing Works

Fatigue testing uses cyclic loading to determine the lifespan of a material or product under conditions of fluctuating stress, resulting in cracking or complete fracture. These tests ensure material or product safety in the medical device industry, where failure can result in significant damage or serious injury.

Experts perform fatigue testing under various loads, speeds, and temperatures. The results of these tests predict the lifespan of a material or product and the parts that may endure exposure to demanding conditions. It can also characterize different material properties.

The Importance of Fatigue Testing

Fatigue testing is an essential part of the medical device testing process that determines the behavior of a material or specimen during cyclic loading. Because medical device testing is strictly regulated due to the potential risks associated with the application of a product, fatigue testing is a vital service that an experienced testing company must perform while adhering to details such as stress levels, sample sizes, and other protocols.

Fatigue Testing at ATS' Family of Companies

We provide an array of fatigue and mechanical testing services. With over 55 years of industry experience, we understand the rigors involved in adequately carrying out fatigue testing services. Our team is well-versed in creating test plans, which include technical reports that manufacturers can submit to regulatory bodies in order to meet various industry requirements.

Applied Technical Services’ Family of Companies sets out to develop an appropriate sample size for manufacturers’ medical devices. We base the sample size on factors such as the desired statistical significance, the number of tests needed to achieve statistical confidence, the cost of the test specimens, and the standard deviation.

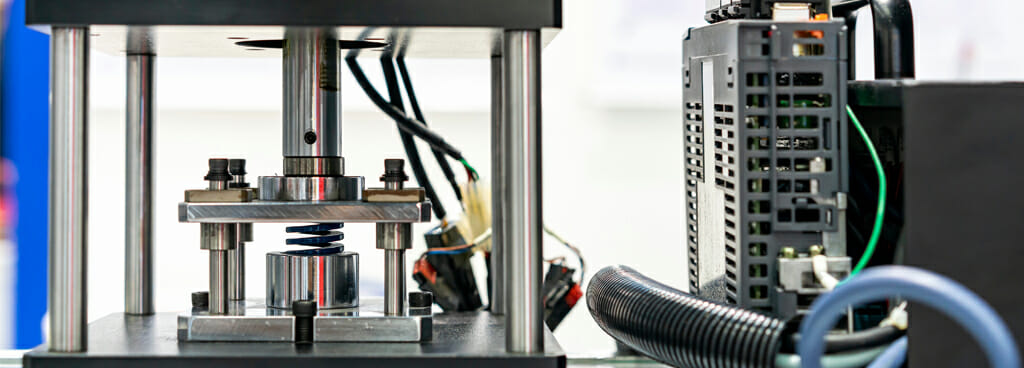

Our Fatigue Testing Lab

Our fatigue testing lab analyzes the fatigue resistance of sample materials. The sample material will accumulate stress due to repeated loading and unloading, which causes a microscopic crack to form and then expand, ultimately leading to a complete fracture in the sample material.

Compliance Standards and Regulations

Applied Technical Services’ Family of Companies maintains several accreditations, including ISO/IEC 17025 accreditation. Our testing labs perform fatigue testing and analysis services on a variety of products, including medical devices, under ISO and ASTM standards.

Contact Us

Contact the mechanical testing experts at Applied Technical Services’ Family of Companies for more information on fatigue testing lab services today and request a free quote.

Request Form

"*" indicates required fields

Medical Device Testing

ASTM Testing

- ASTM F1044 Shear Testing of CaP and Metallic Coatings

- ASTM F1160 Shear and Bending Fatigue of Coatings

- ASTM F1264 Intramedullary Fixation Device Testing

- ASTM F1357 Articulating Total Wrist Implant Testing

- ASTM F1378 Shoulder Prostheses Testing

- ASTM F1541 ESFD Testing

- ASTM F1672 Patellar Prosthesis Testing

- ASTM F1714 Gravimetric Wear Assessment of Prosthetic Hip Design in Simulator Device Testing

- ASTM F1717 Spinal Implant Testing

- ASTM F1781 Elastomeric Flexible Hinge Finger Total Joint Implants Testing

- ASTM F1798 Spinal Implant Subassembly Testing

- ASTM F1820 Modular Acetabular Device Strength Testing

- ASTM F1829 Glenoid Locking Mechanism Shear Testing

- ASTM F1875 Fretting Corrosion Testing of Hip Implant Interfaces

- ASTM 2009 Modular Prostheses Taper Connection Testing

- ASTM F2025 Wear Assessment of Polymeric Components

- ASTM F2028 Glenoid Loosening Testing

- ASTM F2077 Intervertebral Body Fusion Device Testing

- ASTM F2183 Small Punch Testing

- ASTM F2193 Spinal Fixation Components

- ASTM F2267 Measuring Subsidence of Intervertebral Fusion Devices

- ASTM F2346 Standard and Dynamic Testing of Artificial Intervertebral Discs

- ASTM F2423 Wear and Fatigue Testing of Total Disc Prostheses

- ASTM F2502 Absorbable Plate and Screw Testing

- ASTM F2554 CAS System Precision Testing

- ASTM F2624 Static, Dynamic, and Wear Testing of Extra-Discal Spinal Implants

- ASTM F2624 Spinal Implant Dynamic Testing

- ASTM F2694 Lumbar Total Facet Prosthesis Testing

- ASTM F2706 Spinal Implant Fatigue Testing

- ASTM F2789 Mechanical and Functional Characterization of Nucleus Devices

- ASTM F2790 Static and Dynamic Testing of Total Facet Prostheses

- ASTM F382 Metallic Bone Plates Testing

- ASTM F384 Angled Orthopedic Fixation Testing

- ASTM F543 Metallic Medical Bone Screw Testing

- ASTM F564 Metallic Bone Staple Testing

ISO Testing

- Biocompatibility Testing for Medical Devices ISO 10993

- ISO-10328 Structural Testing of Lower Limb Prosthetics

- ISO 10993 Biocompatibility

- ISO 10993 Biocompatibility Testing

- ISO 10993 Testing

- ISO 10993 Testing Lab

- ISO 18192-1 Wear Testing for Intervertebral Disc Prostheses

- ISO 12189 Fatigue Testing of Flexible Spinal Implants

Medical Device Testing

- Fatigue Testing Lab

- Implant Testing

- Material Testing Laboratory

- Material Device Regulatory Compliance Testing

- Medical Device Testing

- Medical Device Testing Certification

- Medical Device Materials Testing

- Medical Device Materials Testing Consulting

- Medical Device Mechanical Testing

- Medical Device Mechanical Testing Regulations

- Medical Device Performance Testing

- Medical Device Product Testing

- Medical Device Reliability Testing

- Medical Device Standards Testing

- Medical Device Standards Testing Certifications

- Medical Device Testing Companies

- Medical Device Testing Services

- Medical Device Testing Lab

- Medical Implant Testing Lab

- Orthopedic Device Testing

- Prosthetic Testing

- Prosthetic Testing Services