- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

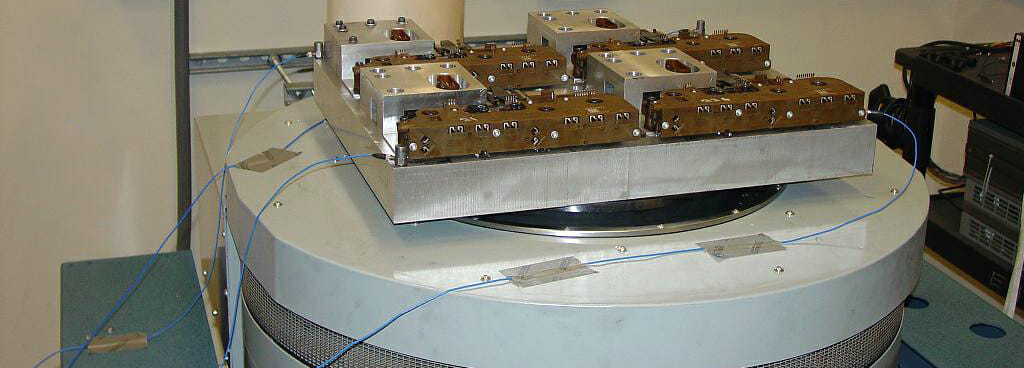

Shaker Table Testing

Applied Technical Services conducts shaker table testing to ensure the resilience of client products and that they comply with industry standards and government regulations.

ATS performs both sinusoidal and random vibration shaker table testing, with the testing method used depending on the subject’s intended function.

Sinusoidal Testing

This testing method subjects a device to one vibration frequency at a time, which may be used to determine the resonant frequency of the device or to induce fatigue in order to observe potential flaws and risk of failure.

Random Vibration Testing

This testing method subjects a device to several different vibration frequencies simultaneously, approximating the “background noise” endemic of most operating conditions. This is also used to simulate forces the device will be subjected to during transit.

The Purpose of Shaker Table Testing

Vibrational forces add up over time, potentially causing damage that can ultimately lead to failure. ATS’ vibration testing services are available both before production to validate product design and after production to determine the life expectancy of a product.

Testing Standards and Specifications

ATS adheres to the following standards during vibration testing:

Applied Technical Services

Founded in 1967, Applied Technical Services is the nation’s leading industrial testing service provider. Our highly trained technicians are ISO 9001 certified and ISO 17025 accredited by the A2LA and strive to achieve the highest level of customer satisfaction on every project. We adhere to a rigorous quality assurance program to ensure our clients receive the best possible service and detailed, accurate reporting. Contact ATS today to schedule your next shaker table testing services.

Request Form

"*" indicates required fields