ATS provides FAC testing to help clients prevent major failures. Flow-accelerated corrosion (FAC) occurs when fast-flowing fluid or steam dissolves the protective layer on the interior walls of pipes and vessels. This phenomenon leads to an increase in corrosion, causing wall thinning, leaks, and instantaneous ruptures. FAC often occurs in areas with high flow rates, such as tube inlet ends, pump impellers, and pipe blockages. Temperature, pH, flow pattern, and metallurgical characteristics also impact the level of corrosion. Flow-accelerated corrosion affects many industries, including steam and nuclear power plants.

Corrosion Testing Methods

ATS utilizes several forms of nondestructive testing (NDT) to evaluate pipes, pressure vessels, and other components for erosion and corrosion. Our non-invasive techniques do not impact the structural integrity of your components, thus reducing costs while providing vital information regarding equipment health and necessary maintenance.

Visual Inspections

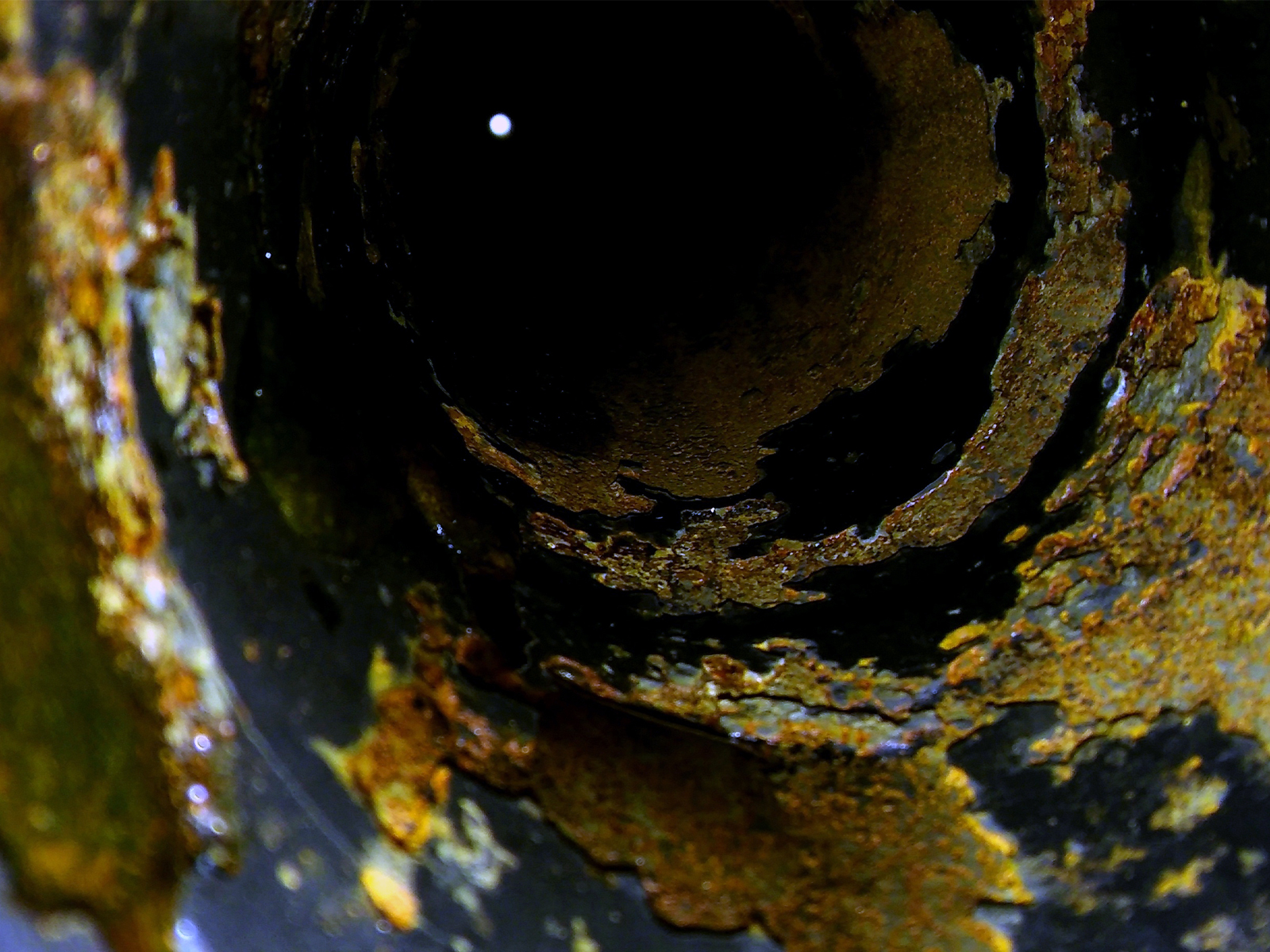

Technicians use visual inspections to evaluate FAC in large equipment such as deaerators and other vessels susceptible to this type of damage. Visual inspection is an effective method for identifying flow-accelerated corrosion and establishing a plan for necessary actions moving forward. Our certified experts have ample experience assessing FAC and determining the most economical solution on a case-by-case basis.

Ultrasonic Thickness Testing

Ultrasonic testing can determine material thickness in piping, vessels, and other equipment. The gauge emits ultrasonic waves and measures the time they take to echo back to calculate thickness. Areas with wall thinning may indicate the presence of FAC. Ultrasonic testing only requires access to one side of the equipment and works on parts of any size of configuration. This portable, cost-effective method produces rapid results, allowing the proprietor to make prompt, informed decisions regarding their equipment. Phased array testing is an advanced ultrasonic inspection method that utilizes multiple elements within the same ultrasonic transducer. This method produces a detailed image of the components’ thickness so technicians can easily identify erosion and/or corrosion.

Pulsed Eddy Current Inspections

Pulsed eddy current inspections can identify thin, eroded areas on equipment walls where FAC may have occurred. This portable test works through insulation and can inspect complex shapes. This inspection is used as a filter to identify areas of concern, then ultrasonic testing is performed to determine thickness of the component.

Our NDT Services

Applied Technical Services is one of North America’s leading providers for NDT. Our experience, responsiveness, and professionalism have earned us a high reputation in several industries, including:

- Chemical

- Power Generation

- Maritime

- Petrochemical

- Manufacturing

- Automotive

- Aerospace

- Construction

- Welding

ATS offers quick reporting of detailed, accurate data. Our engaged experts can answer any questions about testing or data. If you could benefit from FAC testing, contact ATS today.