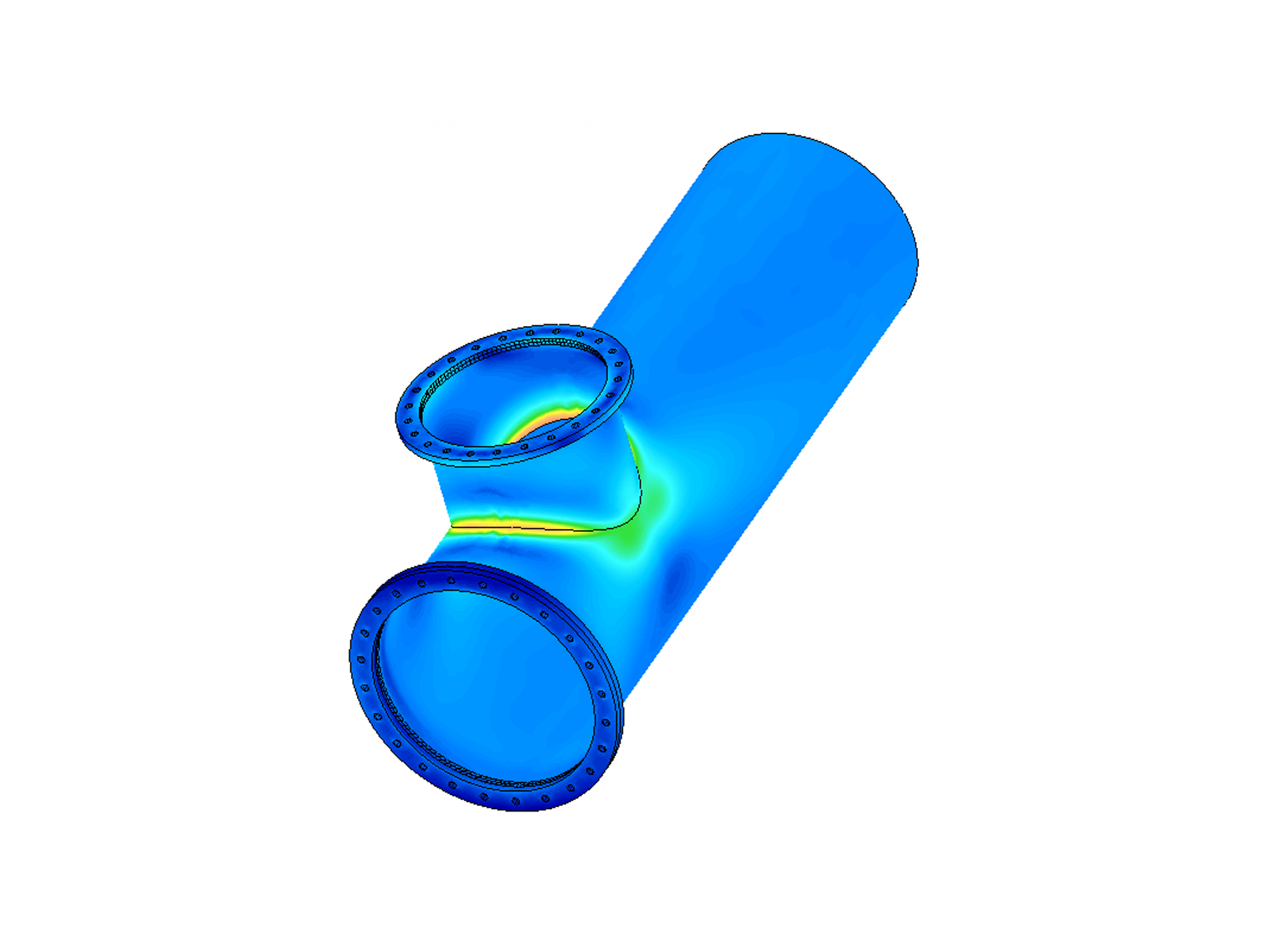

Applied Technical Services (ATS) uses the latest Solidworks Simulation software package to perform thermal analysis on a wide variety of parts, systems, and assemblies. Mechanical systems or parts may behave differently under additional thermal loadings which can lead to breakdown, cracking, seizing, yielding, or other types of adverse behavior. A detailed thermal analysis is often combined with other types of FEA, such as static, buckling or with conjugate heat transfer analysis, to deliver the most accurate results possible.

FEA can be used to simulate the flow of heat through parts and assemblies due to environmental conditions, friction, electrical or steam power, in additional to numerous other sources of heat input. Parts or assemblies which operate under a wide range of temperatures, or extremely high or low temperatures, may benefit from a thermal analysis.

Benefits of FEA Thermal Analysis:

- Extend bearing life

- Determine design safety factors under increased operating temperature

- Lower operating costs

- Refine and optimize designs

- Determine sizes of cooling systems

- Evaluate materiall choices based on expected operating temperature

Contact ATS to discuss how a Thermal Finite Element Analysis can help your product or unique design scenario.