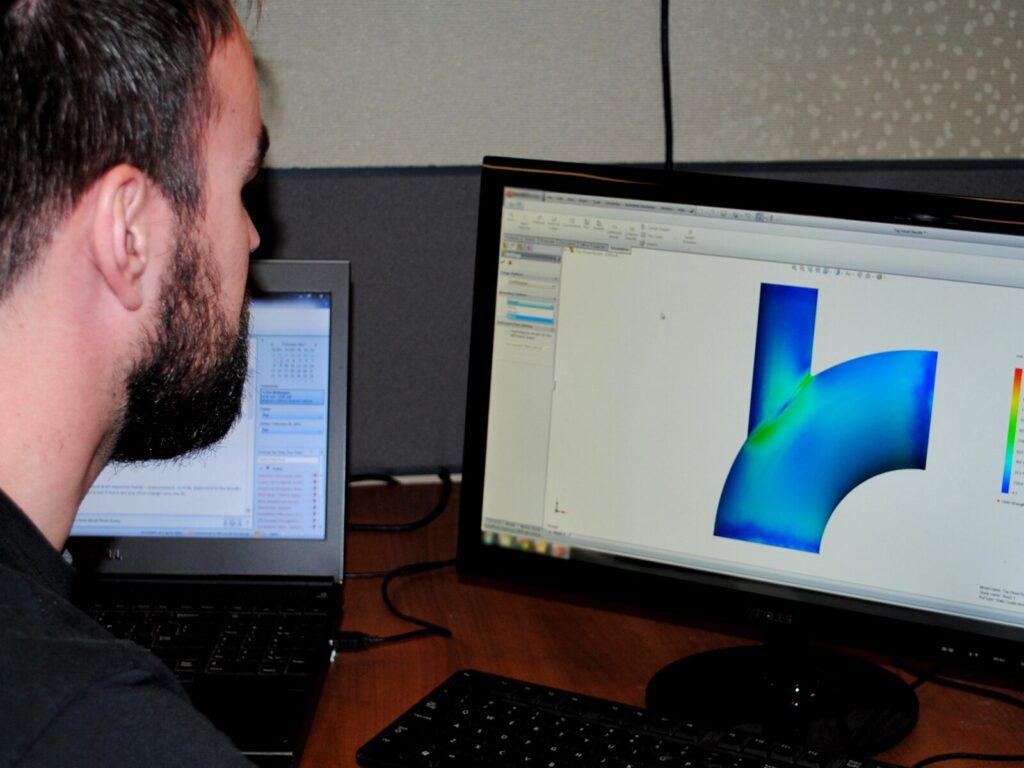

Finite Element Analysis (FEA) Modeling and Simulation

Applied Technical Services (ATS) is a consulting engineering firm with extensive testing, inspection, and analysis capabilities. ATS’ licensed Professional Engineers utilize finite element analysis to simulate structural, vibration, and thermal response which provide predictions of how your systems will perform. Results of finite element analysis can be evaluated and compared to codes, standards or customer specifications.

Linear or Nonlinear FEA

ATS’ licensed Professional Engineers (P.E.) develop static or transient, linear or nonlinear finite element models to evaluate structural and thermal responses. These finite element analyses produce detailed time or frequency histories, graphs and contour plots of stress, structural, and thermal loads, and deformation under various loads or service conditions.

FEA Convergence

Our engineers are committed to quality. A finite element analysis is only as good as the accuracy of the geometry, boundary conditions, load characterization, and material properties assigned. Our analysts’ design experience produce advanced 3D CAD and FEA models with properly integrated meshes for precise structural and thermal representations. Our validity checks include convergence analysis, review of constraints, loads, and when needed, additional codes or analytical solutions to provide confidence in our results.

Backed by In-House Testing and Failure Analysis Experts

Finite element representations of critical system components can be validated with in-house testing and failure analysis capabilities. If geometry data is unavailable, ATS can reverse engineer components using the latest scanning technology for precise measurements, and through chemical and mechanical testing determine material composition, mechanical properties, and material defects.

FEA Capabilities

- Suspension and Fall Arrest Anchorage Systems

- Tank, Vessel, and Piping Systems “Fit for Service”

- ASME Sec. VIII, Division 2 Analysis

- Structural / Thermal Coupling

- Shock / Explosive / Impact Loading

- Modal / Frequency Response Analysis

- Nonlinear / Time Response Analysis

- Fatigue and Buckling

- Materials Selection / Characterization

- Design and Structural Optimization

- Product Development, Validation Testing, and Failure Analysis

- Conduct physical testing (tensile strength, material composition, etc.) for FEA use