Applied Technical Services’ metallurgy lab conducts plating thickness measurements. We employ polite and passionate professionals who prioritize customer service and quality.

What is Plating Thickness, and Why is it Important?

Materials undergo plating to improve the functionality of an object. Manufacturers use plating for several products, including jewelry, kitchen appliances, and automotive parts. Plating has multiple uses, including:

- Harden Materials

- Cosmetic Improvements

- Prevent Corrosion

- Improved Weatherability

- Reduce Friction

- Radiation Shielding

Plating thickness measurements are important because a coating’s durability depends on the coating’s thickness. Thicker coatings provide more protection, whereas thinner or uneven coatings leave the material exposed to corrosion, causing premature failure. Improper plating leads to partial coverage, negatively affecting the appearance and performance of the coating. Plating thickness measurements help ensure that coatings are appropriately applied, preventing the complications that accompany poor plating.

Measuring Plating Thickness

Our Metallurgy lab uses the following instruments to measure plating thickness.

X-Ray Fluorescence Spectrometer

An X-ray fluorescence spectrometer (XRF) is a nondestructive instrument that uses X-rays to determine the thickness of various metallic coatings. There are several benefits to using XRF instruments, including:

- Elemental Imaging

- Penetration Depths

- Qualitative and Quantitative Results

- Nondestructive Testing

- Simultaneously Analyze Several Materials

- Portable, Allows for On-site Testing

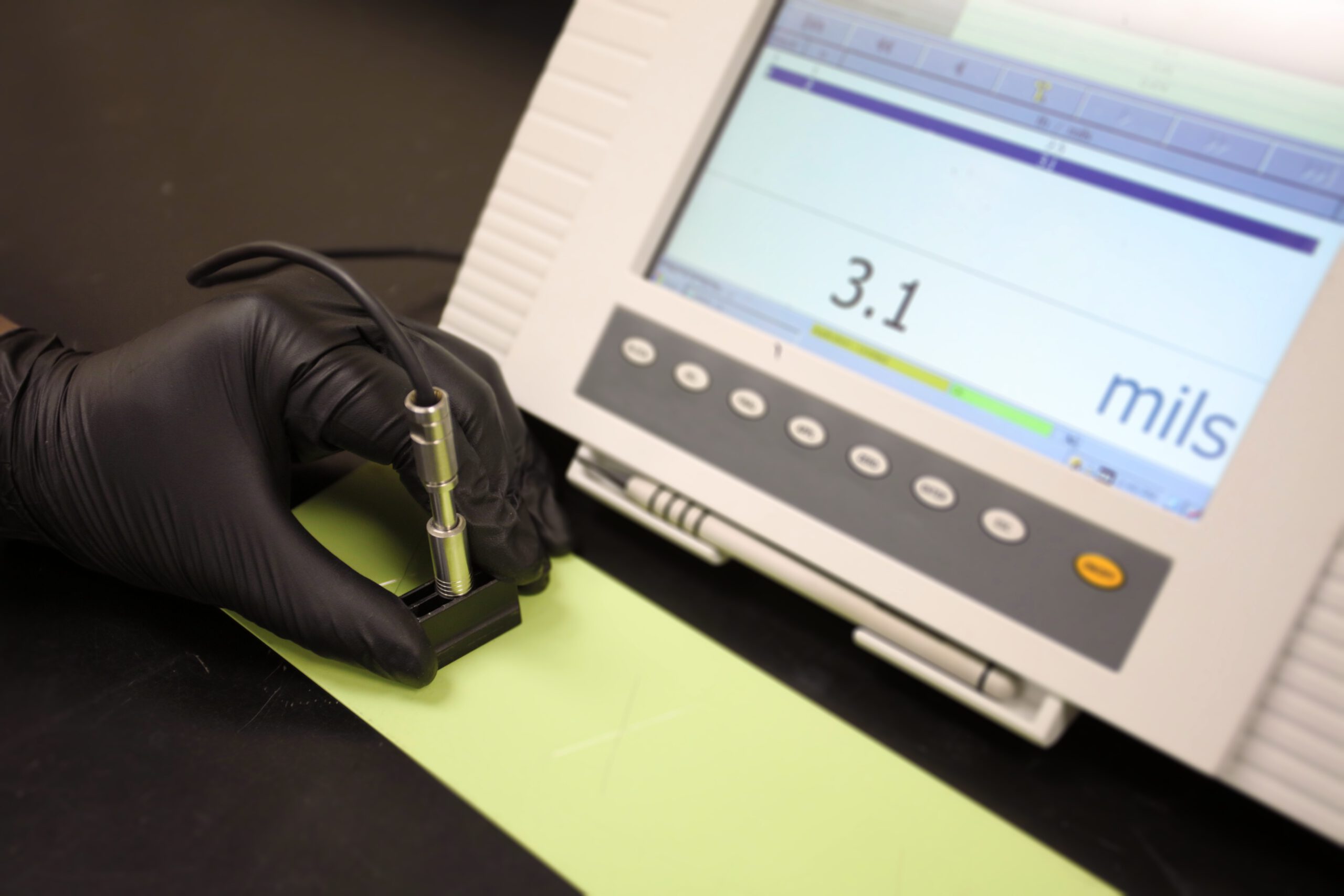

Eddy Current Thickness Gauges

An eddy current thickness gauge measures the thickness of non-conductive coatings on non-magnetic substrates such as copper, aluminum, and brass. ECT gauges detect common coating defects, including corrosion, cracking, erosion, thickness loss, and material degradation. ECT gauges have multiple benefits, including:

- Minimal Preparation

- Multi-layer Detection

- Detects Surface Defects

- Doesn’t Require Direct Contact with Surface

- Nondestructive Testing

- Portable, Allows for On-site Testing

Plating Thickness Services

ATS offers thickness testing for the following types of plating.

- Aluminum (anodized)

- Brass

- Cadmium

- Chromium

- Copper

- Gold

- Nickel

- Siler

- Tin

- Zinc

- Zinc Iron

Applied Technical Services Metallurgy Lab

Our metallurgy provides plating thickness measurements, failure analysis, litigation support, and other metallurgical services for clients in various industries worldwide, including:

- Aerospace

- Automotive

- Communications

- Construction

- Consumer Products

- Healthcare

- Manufacturing

- Nuclear

- Oil and Gas

Our lab experts keep an open line of communication with clients to ensure that our services fit the scope and needs of their projects. Our lab is accredited, and our testing experts follow the guidelines established by the American Society for Testing and Materials to ensure that clients receive satisfactory service. Contact us today and receive a free quote for our plating thickness services.