Applied Technical Services’ technicians offer professional coating services, including zinc plating thickness measurements and coating testing and inspection services. Our metallurgy lab employs chemists, engineers, and other specialists with decades of shared experience in various metallurgy services.

What is Zinc Plating, and What are its Advantages?

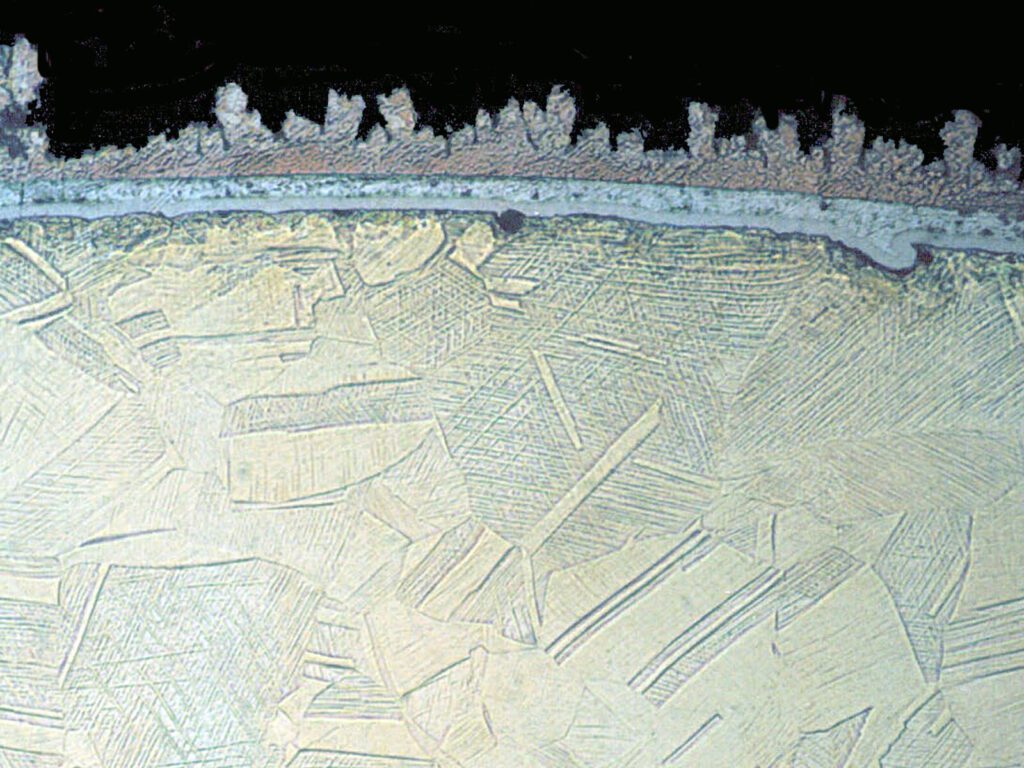

Galvanization, or zinc plating, covers substrate metals such as iron and steel with a zinc coating to protect the material from corrosion. The zinc coatings serve as a sacrificial anode, creating a physical barrier between a substrate and potentially corrosive elements.

There are multiple types of zinc coatings, including:

- Acid Zinc

- Black Zinc

- Blue Zinc

- Continuously Galvanized Sheet

- Galvanized Pipe and Tube

- General or Hot Dip Galvanizing

- Mechanical Plating

- Thermal Diffusion Galvanizing

- Yellow Zinc

- Zinc Cobalt

- Zinc Electroplating

- Zinc Metal Spraying

There are several benefits to zinc plating, including:

- Corrosion Resistance

- Environmentally Friendly

- Aesthetic Improvement

- Increased Strength

- Scratch Resistance

- Cost-efficient

Understanding Zinc Plating Thickness

The protection provided by zinc plating is proportional to the plating’s thickness, so thicker platings offer more protection for the metal. Environmental conditions are essential to consider when determining the ideal thickness of a zinc plating. For example, dry and well-kept conditions indoors require less thickness than outdoor conditions where materials endure more corrosive elements.

ASTM Standards

- ASTM A123/A123M

- ASTM E376

- ASTM A153/A153M

- ASTM A653/A653M

- ASTM A767/A767M

- ASTM D7091

About Applied Technical Services

As an ISO 9001:2015 registered quality management system, Applied Technical Services is committed to excellent customer service and continuous growth and improvement. Founded in 1967, ATS provides quality testing, inspection, and engineering consulting services and has served clients in a wide range of industries across the globe, including:

- Aerospace

- Automotive

- Communications

- Construction

- Consumer Products

- Defense

- Healthcare

- Manufacturing

- Nuclear

- Oil and Gas

- Pulp and Paper

- Power Generation

- Renewable Energy

Our lab technicians communicate with clients to ensure that our services are satisfactory and address the scope and needs of the client’s project. We provide quick services without compromising quality and provide clear and concise reports to clients throughout the service process.

Please don’t hesitate to contact us today at +1 (888) 287-5227 and ask about our coating and plating services.