Additive Manufacturing Testing

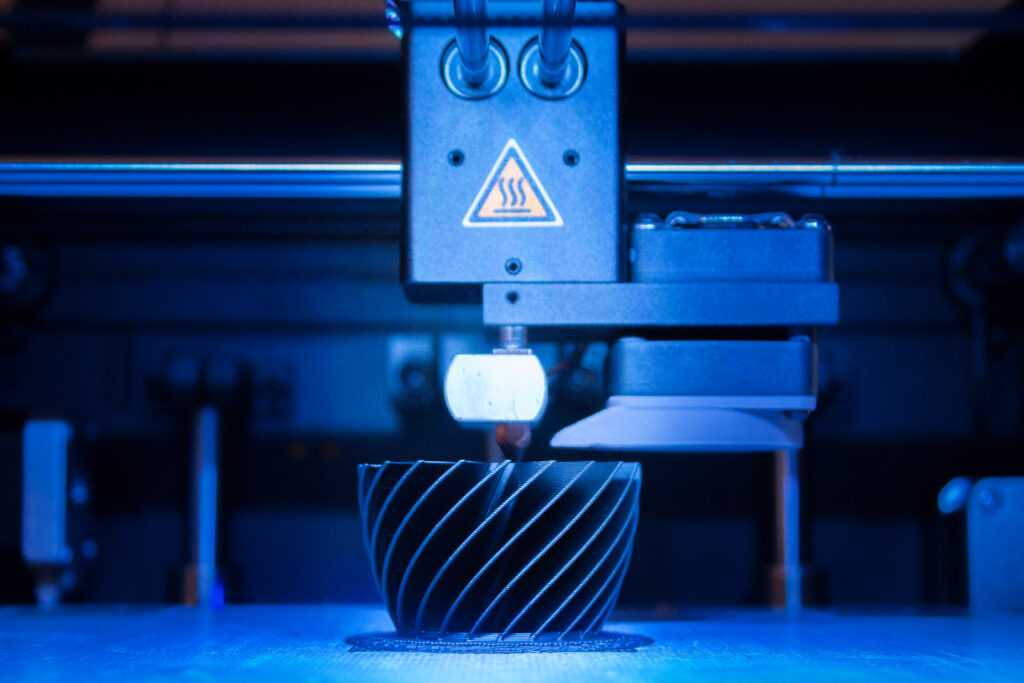

Additive manufacturing is a rapidly growing sector within the aerospace, medical, and automotive industries. Through additive manufacturing, also referred to by the layman’s term 3D printing, specialized components are used to create objects from powder source material in multiple layers. This methodology minimizes material waste and creates opportunities to use a wide range of composites, plastics, or metals.

Before the components can be sold or used, a thorough round of additive manufacturing chemical and mechanical testing must be completed on the components. The feedstock powder metals, ceramics, or polymers used to create the objects are all tested during this vital stage. We complete these rigorous tests to verify that each object meets the highest performance, safety, and quality standards.

Testing Standards

Our additive manufacturing testing is completed to the following standards:

- ASTM F2924-14

- ASTM F3001-14

- ASTM F3049-14

- ASTM F3055-14a

- ASTM F3056-14e1

- ASTM F3091/ F3091m-14

- ASTM F3184-16

- ASTM F3187-16

- ASTM F3213-17

- ATSM F3301-18

- ASTM F3302-18

- ISO/ASTM 3302-16

AM Testing Methods

Our additive manufacturing testing labs offer a range of analysis methods to help AM clients improve the quality of their products. Our testing experts achieve this by validating their printing processes and assessing the performance characteristics of the resulting products.

Chemical Testing

For instance, our chemists perform cleanliness testing to ensure additively manufactured parts are free of contaminants, the inclusion of which can undermine the performance of mission-critical components. Another method we use to validate AM processes is particle size analysis, which allows our powder characterization lab to examine the uniformity of particles in samples. This is important to additive manufacturing for its applications in qualifying feedstocks to promote positive flow rates.

Mechanical Testing

Additionally, we observe the physical performance qualities of AM components using a variety of mechanical testing methods. ATS recognizes that specimens created through additive manufacturing display a lower tensile strength than do those products made through more conventional methods such as injection molding. To account for this disparity, our technicians subject sample components to rigorous tensile testing. For clients who need to determine the long-term durability of their additively manufactured sample, our technicians can project its lifespan by exposing it to fatigue testing, either to a predetermined amount of cycles or until the specimen fails.

Nondestructive Inspections

Finally, we detect AM samples’ unseen defects and determine their adherence to design specifications by scanning them with computed tomography. This advanced imaging technology exposes subjects to a series of x-rays that yield highly detailed 3D models displaying both internal and external features. These CAD models can be used for flaw detection, volumetric measurement, dimensional inspection, reverse engineering, or failure analysis purposes.

ATS Is a Trusted Testing Partner

We support clients across various sectors, including the aerospace, medical, and automotive industries. By testing to internationally recognized standards, we can validate the additive manufacturing methods used to create mission-critical components. As a trusted partner, we complete stringent additive manufacturing testing to ensure that all materials and products are safe for use.

About ATS

As a leading engineering firm, we are proud to specialize in testing and inspections. Our additive manufacturing testing labs have experts who help clients find the technical solutions needed to produce high quality, safe, and valuable products. We leverage our experience, professionalism, and expertise with countless industry standards to effectively serve our national and international clients.

Quality Assurance Programs to Exceed Client Expectations

At ATS, we are dedicated to exceeding client expectations by providing additive manufacturing testing in accordance with applicable standards and specifications. This dedication includes providing clear and accurate data, delivering test results on time, operating within the ISO 9001:2015 registered and ISO/IEC 17025:2017 accredited (A2LA) programs, and adhering to the ATS Quality System. The ATS Quality System is compliant with recognized domestic and international quality system standards across a multitude of industries. As such, it is our duty to provide testing and inspection services that meet our Quality System requirements, as well as other listed ASTM and industry standards.