In the power generation industry, ensuring the reliability of the turbine components is paramount. To this end, Veracity, a member of the ATS Family of companies, partners with plant managers and maintenance teams to establish a comprehensive borescope inspection program that plays a crucial role in risk mitigation. These inspections offer a non-invasive look into the turbines without dismantling and can help mitigate the risk of unexpected downtime and costly equipment failures.

The Plan: Thorough and Proactive Borescope Inspections

Even the best-run facilities face challenges. Gas turbine components have a finite lifespan and the ability to detect service-induced defects early is key. Early detection can minimize downtime and repair costs, help prevent catastrophic fatigue-related failures, and increase operational revenue. Our approach is simple yet effective and distinguishes us from our competitors.

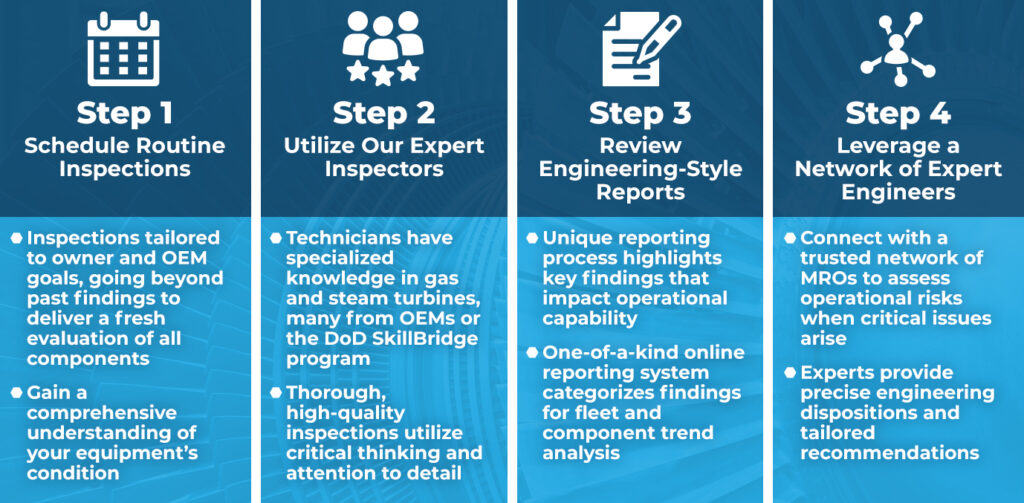

- Step 1: Schedule Routine Inspections. Establish recurring inspections tailored to meet the goals of both the owner and the OEM. Utilizing advanced borescopes and leveraging our seasoned technicians, we conduct a thorough inspection of your turbines, focusing on the service bulletins and fleet inspection data our 20-plus years of borescope experience. Our inspections don’t just focus on what was seen last time but more importantly, they provide a 100% new evaluation of all components as if it was our first time looking at the unit. Upon completion of the inspection, you will gain the confidence that comes from a comprehensive understanding of your equipment’s condition.

- Step 2: Utilize Our Expert Inspectors. With extensive experience and specialized knowledge and training in the Gas and Steam turbine industry, our technicians excel in borescope inspections. Many of our inspectors came from the OEM or transitioned from the Department of Defense SkillBridge program. That program facilitates the continuation of similar career paths for veterans, allowing them to leverage the skills and integrity instilled during their military service. These skills and values provide our technicians with the critical thinking, attention to detail, and hands-on experience necessary to perform this vital work.

- Step 3: Review Engineering-Style Reports. Our unique reporting process focuses on the findings that allow the end users to determine operational capability. Our reports are generated through a proprietary integrated online reporting program that captures and categorizes the findings to provide future fleet or component trend analysis.

- Step 4: Leverage a Network of Trusted Maintenance Repair Organizations. When borescope inspections reveal critical issues, we connect you with a trusted network of Maintenance Repair Organizations that have the experts available to help you determine your operational risk. These experts, recognized for their knowledge and innovative solutions, provide precise engineering dispositions and tailored recommendations to address specific challenges.

Don’t Wait for The Unexpected

Neglecting regular inspections can lead to catastrophic failures. The safety concerns and maintenance downtime costs can be exorbitant—Take control of your turbine’s health by scheduling a comprehensive borescope inspection today.