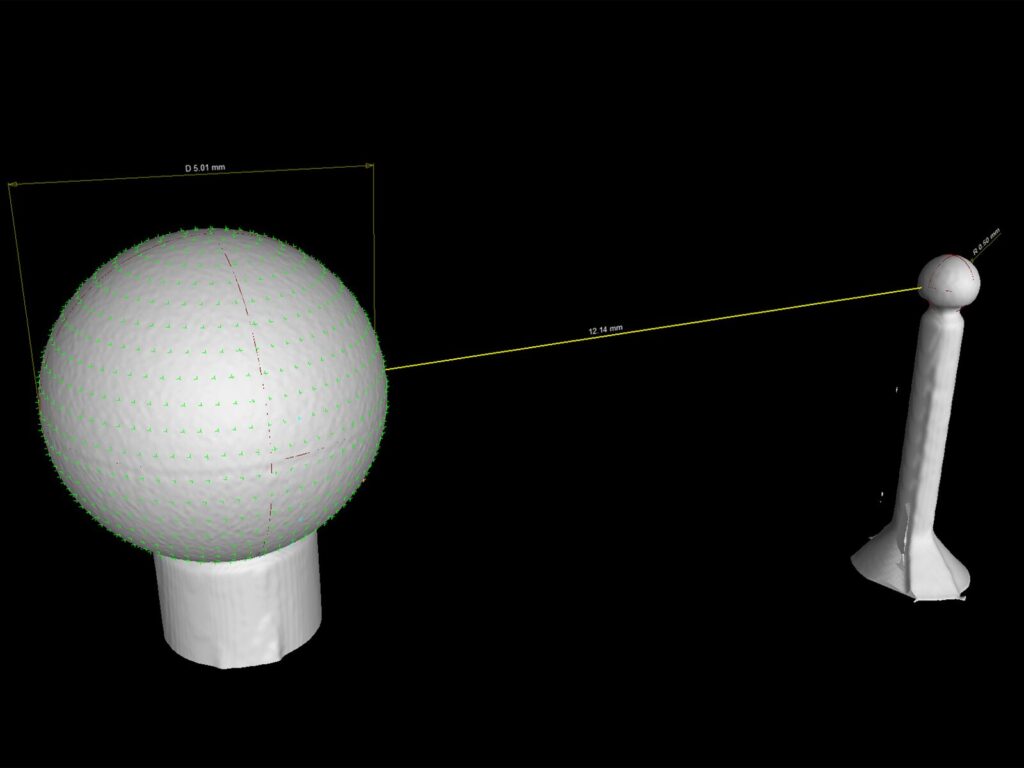

Applied Technical Services offers CT 3D scanning for reverse engineering applications. These technically advanced scans or X-ray inspections provide an efficient way to obtain measurements and build an accurate CAD model for industrial components, equipment, and/or parts.

Computed Tomography (CT) inspections are usually preferred by clients needing both internal and external measurements due to the methods’ cost-effectiveness and efficiency advantages over CMM Laser Scans. Three-dimensional CT scans have numerous applications in Reverse Engineering practices, as they can be utilized in redesigning flawed products, replacing lost CAD files, and developing drawings for legacy components.

Testing Capabilities

ATS employs experienced CT technicians to perform our dynamic 3D Scanning tests. We provide a wide range of applications for our CT Services, such as First Article Inspections, Advanced Porosity Analysis, Scan-to-CAD, and Additive Manufacturing.

Our industrial computed tomography tools include:

- Zeiss Metrotom 1500, 225kV micro-focus

- Annual A2LA calibration

- Certified to accuracy within 4.5 microns

- Analysis volume up to 300 mm (11.75 in) diameter x 600 mm (23.6 in) high

- 50 kg (110 lb) weight limit

- Annual A2LA calibration

- Northstar Imaging X5000

- Multi-Axis Manipulator (x, z, tilt, rotation), able to support up to 250 lb

- CT System scans with spiral acquisition in order to scan elongated objects that cannot fit within a single exposure

- The resolution of the manipulator angle is 0.001 of a degree

- Minifocus 450kV X-ray Machine (0.016” Focal spot at 3mA)

- Dual-energy capability with 225kV Microfocus X-ray Machine (As low as 0.0002” Focal size based on voltage)

- Multi-Axis Manipulator (x, z, tilt, rotation), able to support up to 250 lb

Applied Technical Services – A Reliable Testing Provider

For over 50 years, ATS has earned and maintained an excellent reputation for providing accurate testing and inspection services, uncovering facts in Nondestructive Testing, Materials Testing, Forensic Analysis, and Metallurgy. We work with clients from industries spanning both national and global markets, including those in the fields of aerospace, automotive, defense, healthcare, manufacturing (both conventional and additive methods), and nuclear energy.

ATS Labs and Lab Experts Deliver Quality Assurance

ATS’ CT Technicians work in accordance with our Quality Assurance program by performing tests and inspections that follow the applicable industry standards. We employ a variety of experienced personnel, including investigators, well-trained technicians, metallurgists, scientists, chemists, and Professional Engineers in several disciplines. We hold several accreditations and certifications, such as Nadcap and recognition as an FAA Repair Station.

ATS is committed to the following policies:

- Employ Qualified and Engaged Personnel

- Conduct Testing and Inspections in Accordance with Applicable Standards

- Provide Clear and Accurate Data

- Deliver All Professional Services in A Timely Manner