Applied Technical Services offers coating thickness measurements for various industries and applications. Our metallurgy lab employs metallurgists, chemists, and lab professionals with decades of combined experience. We provide litigation support, failure analysis, material identification, and other metallurgical services.

What are Coatings, and Why are They Important?

Coatings are thin layers of protective coverings placed on the surface of a material. Coatings help protect surfaces from physical damage and offer some aesthetic improvements. The advantages of coating include:

- Scratch and abrasion resistance

- Heat and fire resistance

- Insulation protection

- Improved sealing ability

- Corrosion resistance

- Improved protection against daily wear and tear

- Nonstick properties

ATS provides the following coating services:

- Electroplating

- Electroless plating

- Liquid coating

- Powder coating

The Importance of Coating Thickness Measurements

A coating’s quality and thickness are important factors in its success. Coating thickness measurements help ensure that surfaces have the appropriate amount of protection. Excessive layering causes sagging, cracking, and wrinkling, whereas under-coating may expose the substrate or fail to prevent rust and corrosion.

How is Coating Thickness Measured?

Mechanical Thickness Gauges

Mechanical thickness gauges are ideal in highly flammable environments or situations where electronic instruments prove challenging to use. ATS technicians place a magnet on the surface of the test material and then remove the magnet to measure the amount of pressure needed for removal. The gauge provides consistent pressure from user to user and is highly portable because of its compact design.

Eddy Current Thickness Gauges

Eddy current thickness gauges use the strength of eddy currents to measure a nonconductive coating’s thickness. This method is advantageous because it doesn’t require contact with the surface itself, so it’s ideal for hard-to-reach surfaces.

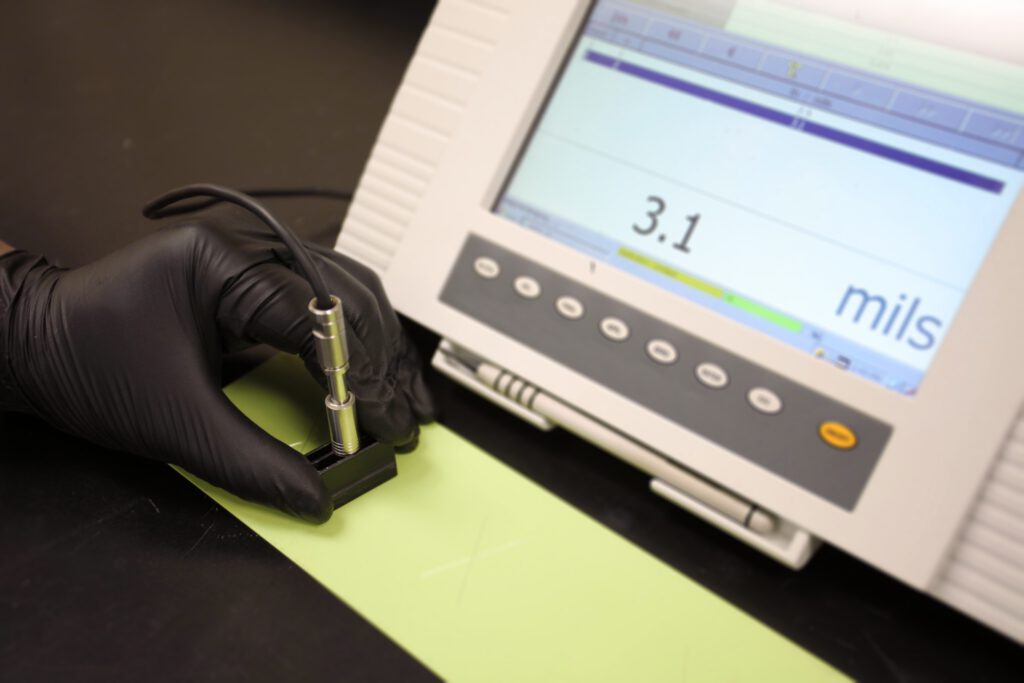

Electronic Thickness Gauges

Electronic thickness gauges are very accurate and perhaps the easiest to operate. Our experts place a magnetic probe onto the coating allowing the instrument to read and display the coating thickness.

About Applied Technical Services

ATS is an industry leader in consulting engineering, testing, and inspection services. Founded in 1967, ATS began on a foundation of customer service and quality, two values we continue to practice today. We cater our coating testing services to clients’ needs while upholding the latest industry practices. Our coating technicians conduct tests in accordance with the following standards:

- ASTM B244

- ASTM D1400

- ASTM D12-91

- ASTM A90

- ASTM B137

- ASTM D7091

- ASTM D3276-15

We offer coating testing services for several industries, including:

- Aerospace

- Automotive

- Construction

- Consumer Products

- Electronics

- Healthcare

- Manufacturing

- Oil and Gas

- Power Generation

Contact Us

Call +1 (888) 287-5227 and request a free quote for your coating thickness measurements.