Applied Technical Services conducts zinc plating thickness measurements for several types of zinc coatings. Our metallurgy lab performs dozens of services for various metals, coatings, and plating. Our full-service facilities have the staff and technology to address your metallurgy needs.

The Importance of Plating Thickness

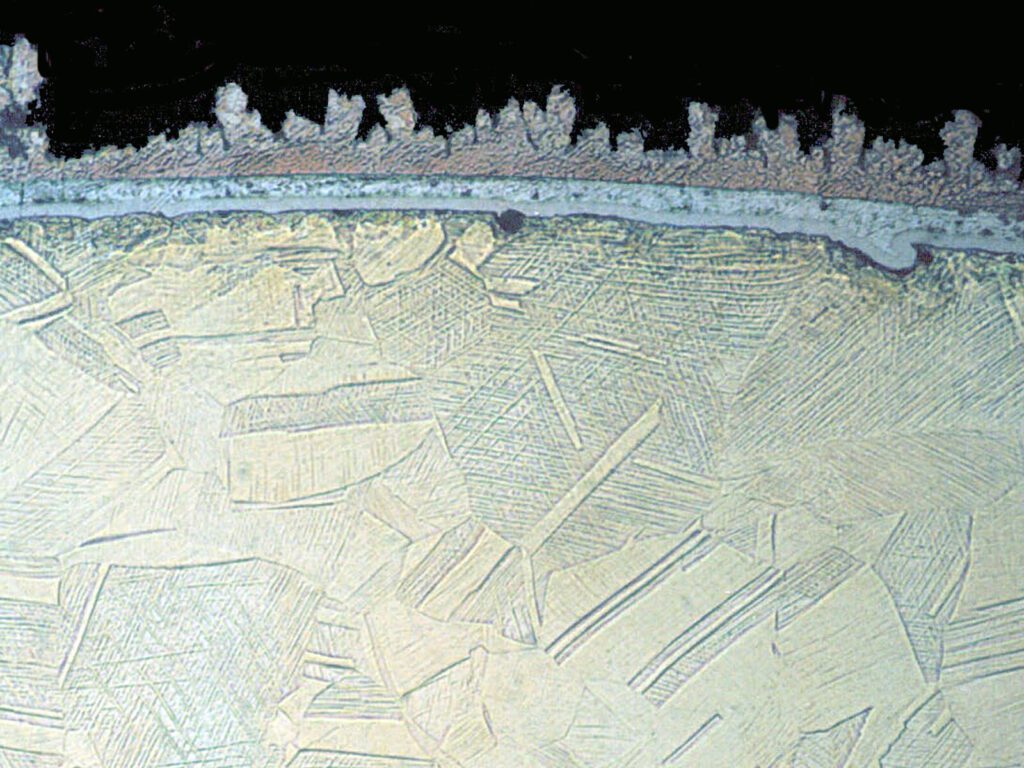

Zinc plating is the process of protecting substrate metals with layers of zinc that serve as a barrier between the substrate and corrosive conditions. The protective qualities of platings are proportional to the plating’s thickness, so thicker zinc coatings offer more protection than thinner coatings. For example, materials placed indoors require much less protection than outdoor materials that are under direct exposure to naturally corrosive elements like water and sunlight.

Corrosion Prevention

Zinc provides sacrificial protection from corrosive elements by serving as an effective metallic barrier between the base metal and corrosion-causing environmental factors. Zinc corrodes nearly 100 times slower than other metals and provides excellent protection from moisture.

Ductility

Zinc is a malleable metal that can endure stretching and bending without breaking.

Environmentally Friendly

Zinc is a recyclable metal with a relatively eco-friendly plating process.

Flexibility

Zinc plating is highly customizable and has several uses, including rack and barrel plating.

Low Cost

Zinc is an abundant metal and easily accessible, making it a cost-effective choice for plating.

Increased Strength

Zinc increases the strength of materials despite being a lightweight material.

High-Temperature Tolerance

Zinc can endure temperatures up to 120 degrees Fahrenheit, reducing cooling costs.

Different Types of Zinc Plating

There are various zinc plating types, each offering varying degrees of corrosion protection. The following are common types of zinc plating.

- Acid Zinc

- Black Zinc

- Clear Zinc (Blue Zinc)

- Zinc Cobalt

- Zinc Gold Passivate

ASTM Standards

- ASTM A123/A123M

- ASTM E376

- ASTM A153/A153M

- ASTM A653/A653M

- ASTM A767/A767M

- ASTM D7091

About Applied Technical Services

Applied Technical Services offers quality engineering consulting, inspection, testing, and training services to clients nationally and abroad. Our commitment to customer service has guided our business practices and principles since 1967. We continue to improve and uphold our history of excellent service by accumulating accreditations and certifications that help expand and improve our services.

Contact us at +1 (888) 287-5227 and request a free quote for our zinc plating thickness services.