Applied Technical Services offers mechanical integrity training services on-site at client facilities. Mechanical integrity inspections for process equipment ensure proper design, fabrication, construction, installation, operation, and maintenance for all parts and components. This type of predictive maintenance is a key component of process safety management (PSM), preventing failures and containment loss. Regularly scheduled inspections, testing, and calculations provide an in-depth understanding of equipment health, allowing proprietors to make deliberate, informed decisions regarding their assets. Mechanical integrity covers maintenance and reliability for fixed assets such as:

- Storage tanks

- Piping systems

- Pressure vessels

- Relief and vent systems

- Recovery and package boilers

- Heat exchangers

- Dryer cans

- Digesters

- Emergency shutdown systems

- Pumps

- Controls

Training Requirements

Starting in 2023, the API (American Petroleum Institute) requires personnel to complete Continuing Professional Development (CPD) hours as one of the recertification requirements for API 653, API 570, and API 510 inspection certifications. Our one-day training course grants attendees a “Certificate of Completion” worth eight CPD hours.

ATS offers training for more than API requirements. Our Licensed Professional Engineers utilize decades of mechanical integrity experience and a variety of certifications to conduct training courses that address all key aspects of mechanical integrity practices.

Course Content

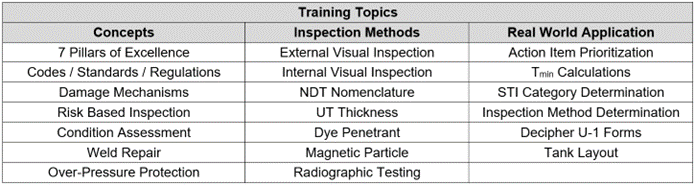

ATS’ mechanical integrity training courses cover a comprehensive range of inspection methods, including external and internal visual inspections, UT thickness, dye penetrant, magnetic particle, and radiographic testing. We also cover NDT nomenclature.

In addition, our program addresses essential concepts involved in mechanical integrity. The seven pillars of excellence serve as the foundation: policy, ownership, asset management, inspection, evaluation, action, and documentation. We discuss applicable codes, standards, and regulations that facilities must maintain compliance with, as well as different approaches to mechanical integrity, including risk-based inspections and condition assessments. Our experts also review the specifics of damage mechanisms, weld repair, and over-pressure protection.

ATS instructors teach attendees real-world applications that are crucial to mechanical integrity practices, such as action item prioritization, inspection method determination, Tmin calculations, STI category determination, deciphering U-1 forms, and tank layout.

See the full list of our training topics below:

ATS Training

As a third-party mechanical integrity consulting company, ATS employs licensed, certified experts in fixed equipment maintenance. Our experts utilize their extensive knowledge and experience to offer on-site training at clients’ locations.

We also offer training for several additional types of industrial testing and inspections, such as reliability testing, failure analysis, rope access, and NDT training. Our diverse staff of specialists can assist clients with all their testing and maintenance training needs.

High-Quality Services

For more than fifty years, Applied Technical Services has provided clients with testing, inspections, consulting engineering, and calibration services. Whether clients need forensic investigations or training services, we promise excellent customer service, quick turnarounds, and accurate, detailed information.

If you need mechanical integrity training, contact us by phone or complete the form on this page.