Weld testing is more than just checking off boxes for compliance—it’s about safeguarding the reliability, repeatability, and safety of welded parts across a variety of industries. Visual inspections can catch surface issues, but more advanced weld testing techniques are necessary to reveal hidden flaws that compromise performance, such as porosity, inclusions, or lack of fusion.

Macro Etch Testing in Action

Consider a scenario where a manufacturer produces welded components for heavy equipment assemblies, relying on high-quality welds to ensure performance and durability. Even though the welded materials appear sound during visual inspection, they send a sample to our lab for quality testing to reveal any issues that may not be immediately apparent.

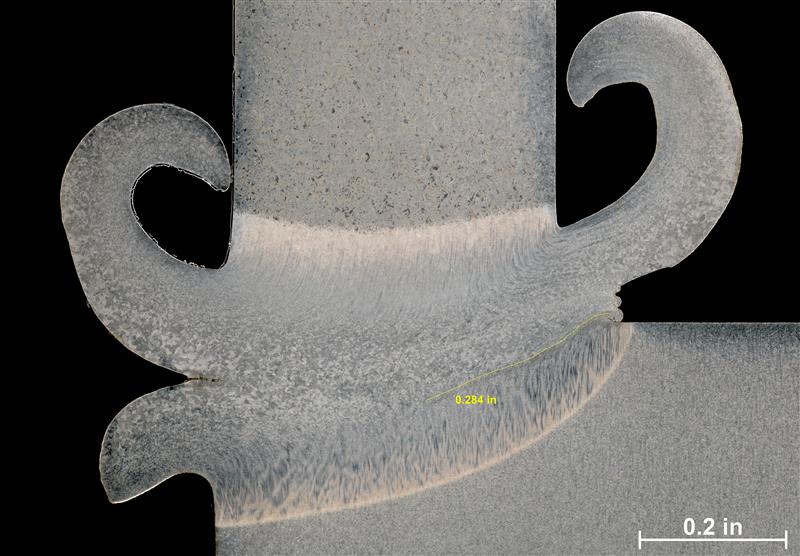

Our technicians section the metal into smaller samples, prepare these cross-sections for assessment, and perform macro etch examinations to reveal flaws beyond the surface. Under magnification, the etched profiles display areas of incomplete fusion to the root of the joint and small pockets of porosity—hidden flaws that may have affected joint performance if left unaddressed.

Early detection allows the client to adjust welding procedures, welding technique, and correct the affected joints to meet compliance. This proactive approach can help reduce costly rework and support the delivery of code-compliant materials designed for long-term performance.

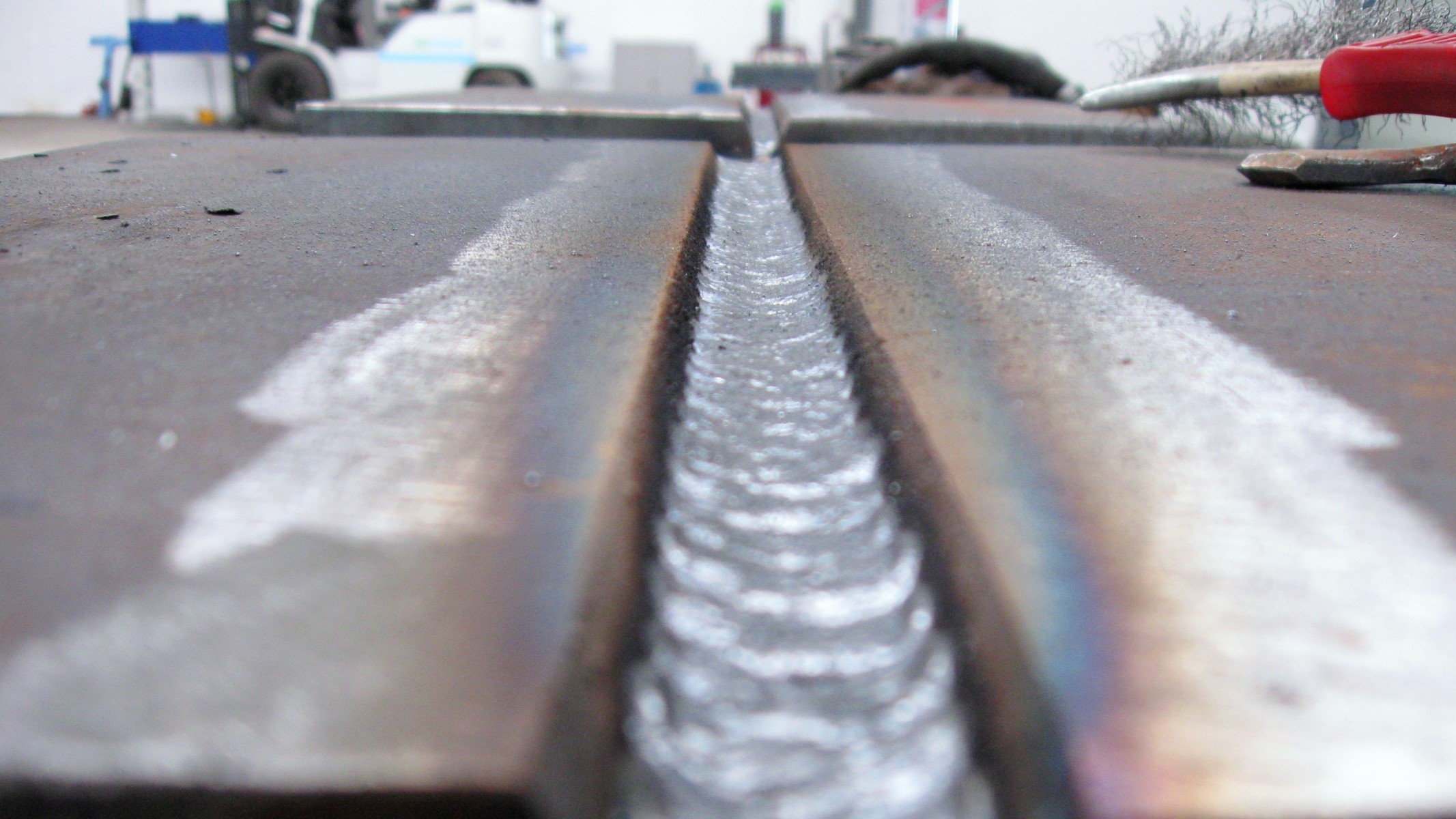

Fillet weld showing complete fusion to both vertical and horizontal members

Macroetch evaluation on the cross-section of dissimilar base metals

Macroetch on a resistance weld

Fillet weld showing porosity — gas or air that gets trapped inside the weld bead during solidification

Our Approach: A Job Weld Done

Our experts empower clients to move from reactive repairs to proactive quality assurance, helping clients gain greater confidence that their welds are prepared to meet real-world demands.

Our weld testing capabilities include, but are not limited to:

- Visual Inspection (VT): The first step in identifying obvious surface defects like cracks or undercutting.

- Non-Destructive Testing (NDT): We use methods like ultrasonic, dye penetrant, and magnetic particle testing to reveal flaws that are either too small to be seen or hidden beneath the surface without damaging the welded parts.

- Macro Etch Testing: Our experts evaluate weld quality by analyzing cross-sections of weld samples. They grind and polish these samples, applying a chemical reagent to accentuate the base metal, heat-affected zone (HAZ), and weld regions. This process reveals flow lines and microstructure for thorough inspection.

- Destructive Testing: Bend, tensile, and impact tests confirm strength, ductility, and overall weld performance.

- Failure Analysis: When weld failures do occur, our root-cause investigations uncover the why and how to prevent recurrence.

We also offer a wide array of other weld testing services, found here.

Contact Us

At Applied Technical Services (ATS), we specialize in weld testing to ASME, AWS, API, NAVSEA, MIL STD, and PED/EN Standards. By partnering with a transparent and knowledgeable provider like ATS, manufacturers can ensure that their welds meet industry standards, help validate welders and procedures, while supporting ongoing quality improvements throughout the product lifecycle.

To learn more about our weld testing services, or to schedule a consultation with one of our welding experts, please use our web request form or give us a call at +1 (888) 287-5227.