Applied Technical Services offers X-ray metrology utilizing computed tomography (CT) scanning to determine whether the geometric characteristics of components, machined parts, sub-assemblies, and finished products comply with their design specs. X-ray metrology verifies that parts, components, and/or products meet relevant specifications — thus ensuring functionality, promoting reliability, and validating product design and/or development.

X-ray Metrology Applications

Advantages of CT over optical coordinate measuring machines (CMMs) and other conventional metrology methods include the speed with which it acquires 3D data (rotational data set minimum of 180°), detector matching, flexible scan parameter, and the capability to accommodate a variety of different component sizes. Another benefit of X-ray scanning is the ability to image the interior of additively manufactured parts, which can have complicated internal geometries. Additionally, ATS provides solutions for our clients who need services related to other CT applications, including research and development, reverse engineering for analytical and testing purposes, duplication, thickness measurements, failure analysis, finite element analysis (FEA), preventative and predictive maintenance, life cycle determination, flaw detection, and porosity characteristics.

X-ray Metrology Testing Capabilities:

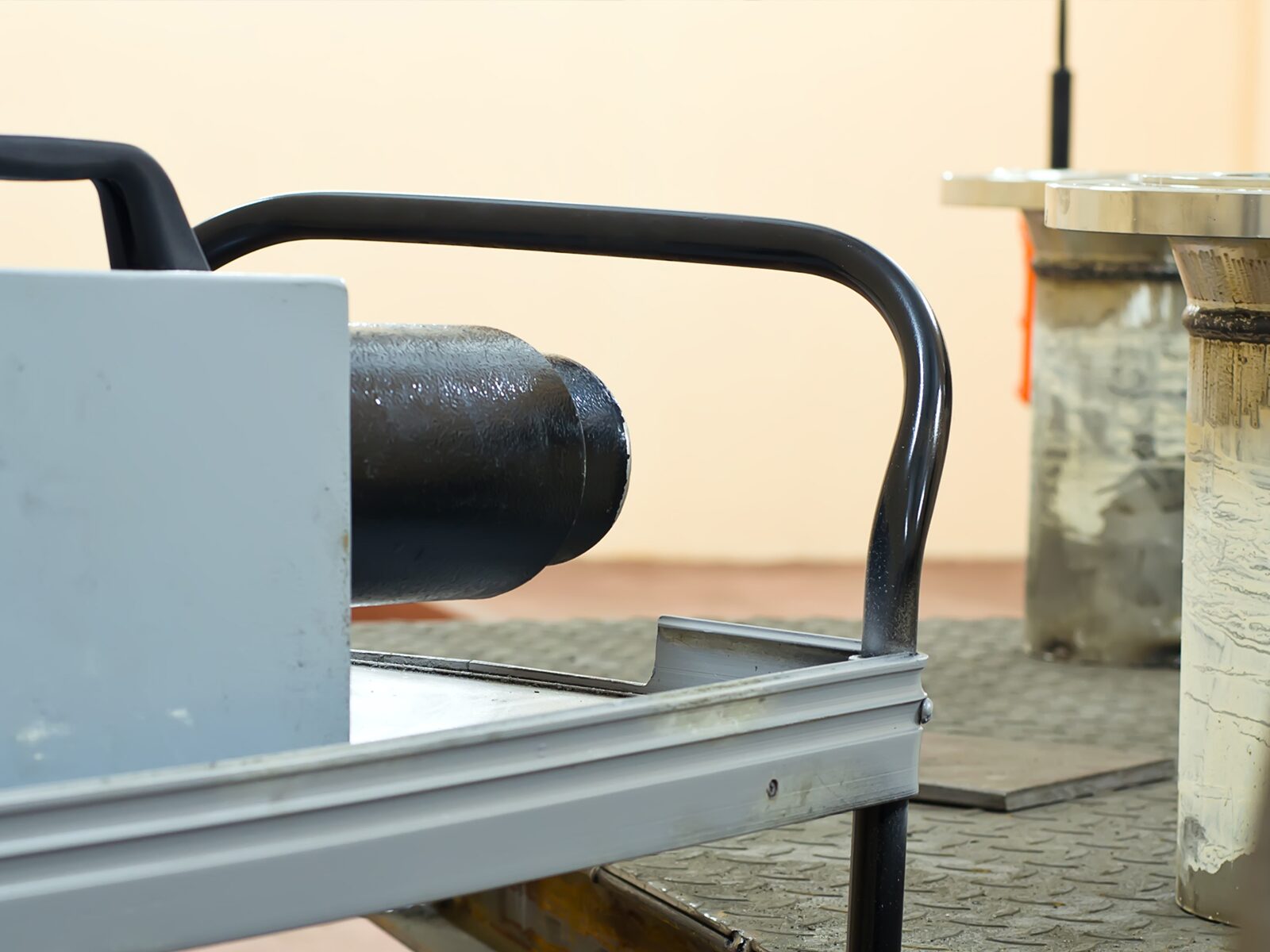

Northstar Imaging X5000

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Capture elongated subjects unable to fit within a single exposure by scanning with a spiral acquisition

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Dual energy capability with 225kV Microfocus X-ray Projector

- Capable to achieve focal size as low as 0.0002” (based on voltage)

Zeiss Metrotom 1500, with a 225kV micro-focus

- Chamber fits specimens up to 11.75 in (300mm) in diameter x 23.6 in (600mm) high. 50 kg (110 lb) weight limit.

ATS Quality Services

Our trained and certified metrologists make use of computed tomography to analyze test materials and rapidly produce accurate findings. ATS performs metrology services in compliance with our ISO 9001:2015 registered quality management system. We uphold stringent quality management standards and practices to enhance the quality of service and maintain accountability for our clients.

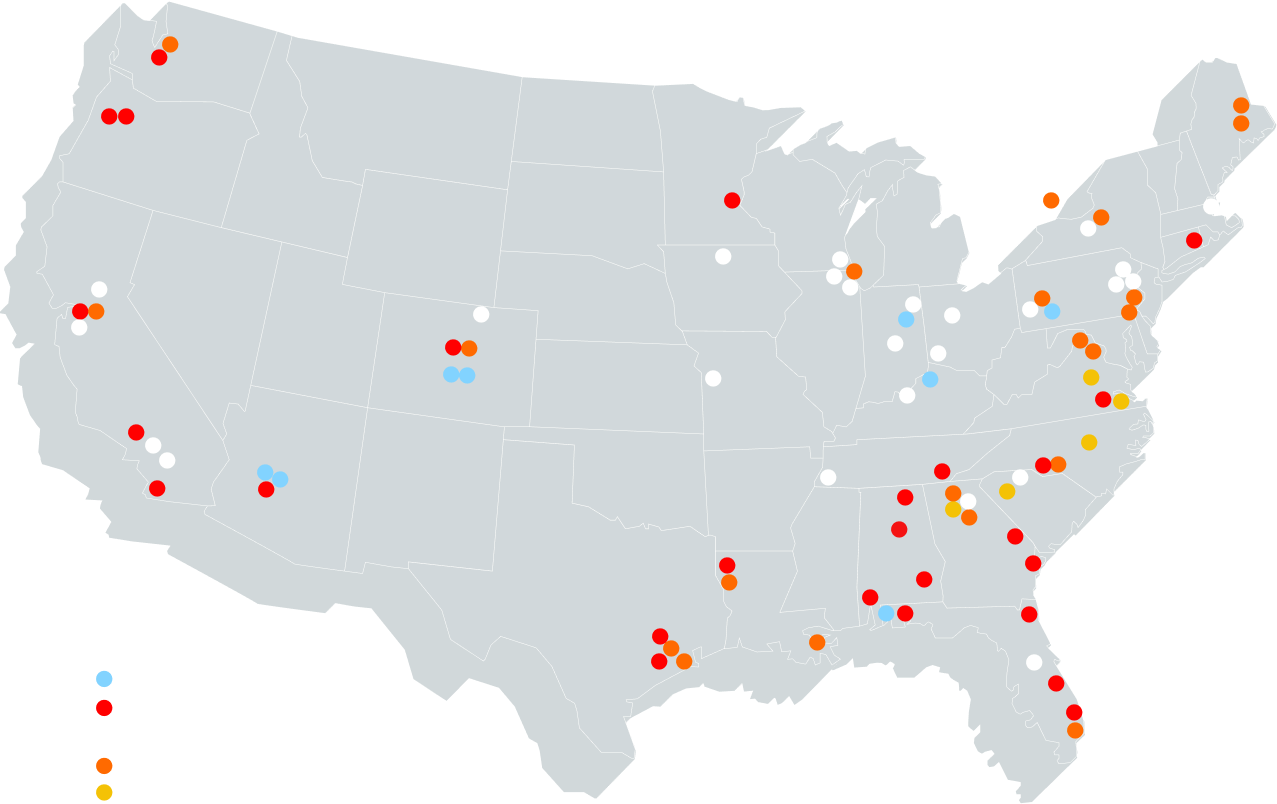

For over 50 years, ATS has partnered with domestic and international customers in aerospace/aviation, additive manufacturing, automotive, consumer products, defense/military, medical devices, nuclear, power generation, steel and aluminum, and weld and fabrication industries. Our goal is to find definitive facts and solutions for our clients in a proactive, efficient, and cost-effective manner as a leader in calibration services. For more information, or to request a quote for our X-ray metrology services, contact ATS today.