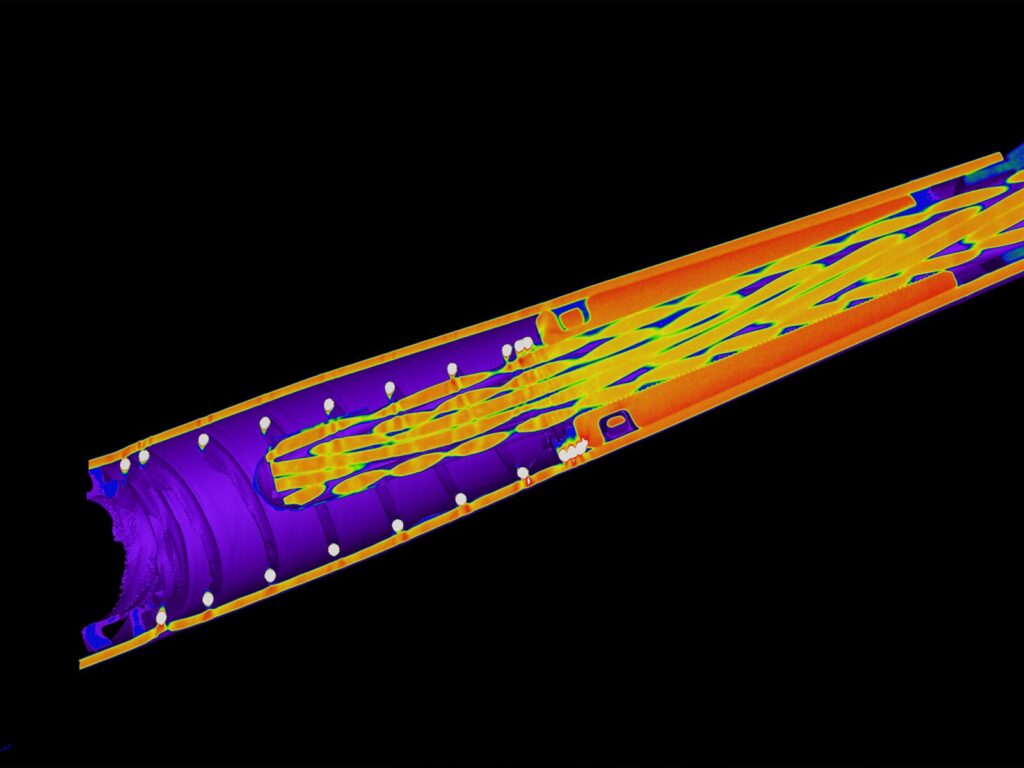

CT Dimensional Inspections determine the geometric characteristics of components, machined parts, sub-assemblies, and products to verify they conform with design specifications. ATS utilizes an innovative technology to ensure products fall within geometric tolerances outlined in their design specifications for functionality, reliability, or product development: Computed Tomography (CT) dimensional inspections. CT dimensional inspections scan parts by collating a series of X-rays into a 3D figure composed entirely of cross-sectional images that our technicians can use to conduct dimensional measurements of both internal and external features. CT offers advantages over conventional and optical coordinate measuring machines (CMMs) as a non-contact nondestructive measurement technology.

Computed tomography allows our specialists to verify the precise dimensions of a part by scanning it to generate a 3D model. Comparing these measurements to its CAD drawing enables them to perform a quantitative assessment of any deviations from the subject’s design. Finding these defects early provides clients the flexibility to modify their production processes to ensure consistency across their production lines. The x-ray facet of CT allows us to verify whether internal features conform to design tolerances without harming the subject —another advantage over tactile measuring methods like CMM.

ATS’ CT dimensional inspections provide quantitative analysis that interprets product evaluation with varying stages of life cycle, development, and manufacturing processes. Furthermore, dimensional inspections serve an imperative quality control purpose when applied to new manufacturing processes and technologies. CT benefits new technologies in industrial production, such as Additive Manufacturing — which can yield complex parts and components that may have inaccessible internal characteristics.

CT also has reverse engineering applications, such as for duplicating parts with no original design specifications or CAD files. In addition to dimensional inspections, CT is capable of thickness measurements, flaw detection, porosity characterization, failure analysis, and finite element analysis (FEA).

Industries Utilizing CT Dimensional Inspections

- Aerospace / Aviation

- Additive Manufacturing

- Automotive

- Consumer Products

- Defense / Military

- Injection Molding

- Manufacturing

- Medical Devices

- Steel & Aluminum

- Weld & Fabrication

Computed Tomography Testing Capabilities:

Zeiss Metrotom 1500, with a 225kV micro-focus

- Chamber fits specimens up to 11.75 in (300mm) in diameter x 23.6 in (600mm) high. 50 kg (110 lb) weight limit.

Northstar Imaging X5000

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Capture elongated subjects unable to fit within a single exposure by scanning with a spiral acquisition

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Dual energy capability with 225kV Microfocus X-ray Projector

- Capable to achieve focal size as low as 0.0002” (based on voltage)

ATS Quality & Experience

ATS’ experienced technicians perform our CT dimensional inspections in compliance with our ISO 9001:2015-registered quality management system. We deliver quick turnarounds to our clients with precise and detailed reporting. ATS manages projects by building customer relationships through attentive communication and providing answers to any pressing questions or concerns. At ATS, our goal is to deliver accurate CT dimensional inspections and solutions combined with industry knowledge, professionalism, and decisive responsiveness that our clients trust. Contact ATS if your company is seeking more information on the latest in metrology measurement advancements.