ATS’ expert 3D part scanning services employs computed tomography (CT) to detect flaws or defects in the structure of product components. Because of the X-ray factor involved in this method, CT provides a view of conditions inside the object, making it a valuable 3D inspection method.

To begin the scanning process, an ATS technician places the sample part in one of our CT chambers. Once secured to a platform and sealed inside, the X-ray projector begins emitting radiation focused in the shape of a cone, fan, or beam. The pedestal raises the subject into the path of these X-rays, which pass through the sample part and hit a detector mounted across from the source. This detector processes a 2D black-and-white image in an operation called tomographic reconstruction based on the levels of energy it picks up. Because more dense materials absorb more of the X-rays than do less dense materials, each tomogram depicts the variation in density between the areas of the subject being scanned.

Once the first tomogram (otherwise known as a slice) is complete, the platform maneuvers the sample part so that a different angle faces the projector. The process repeats for thousands of cycles, each exposure creating a new slice captured from a different orientation from the ones before it. By taking slices of the subject from every possible angle, tilt, rotation, and elevation, our technicians can compile this multitude of 2D images into a single 3D X-ray model. Called a voxel-based point cloud, our experts can convert this dense file into a CAD model for additional utility.

Reasons to Request Our 3D Part Scanning Services

One of the greatest draws to using CT as a part scanning method is its versatility. CT scanning produces a high-resolution 3D model that technicians can manipulate and analyze to various ends.

Metrology

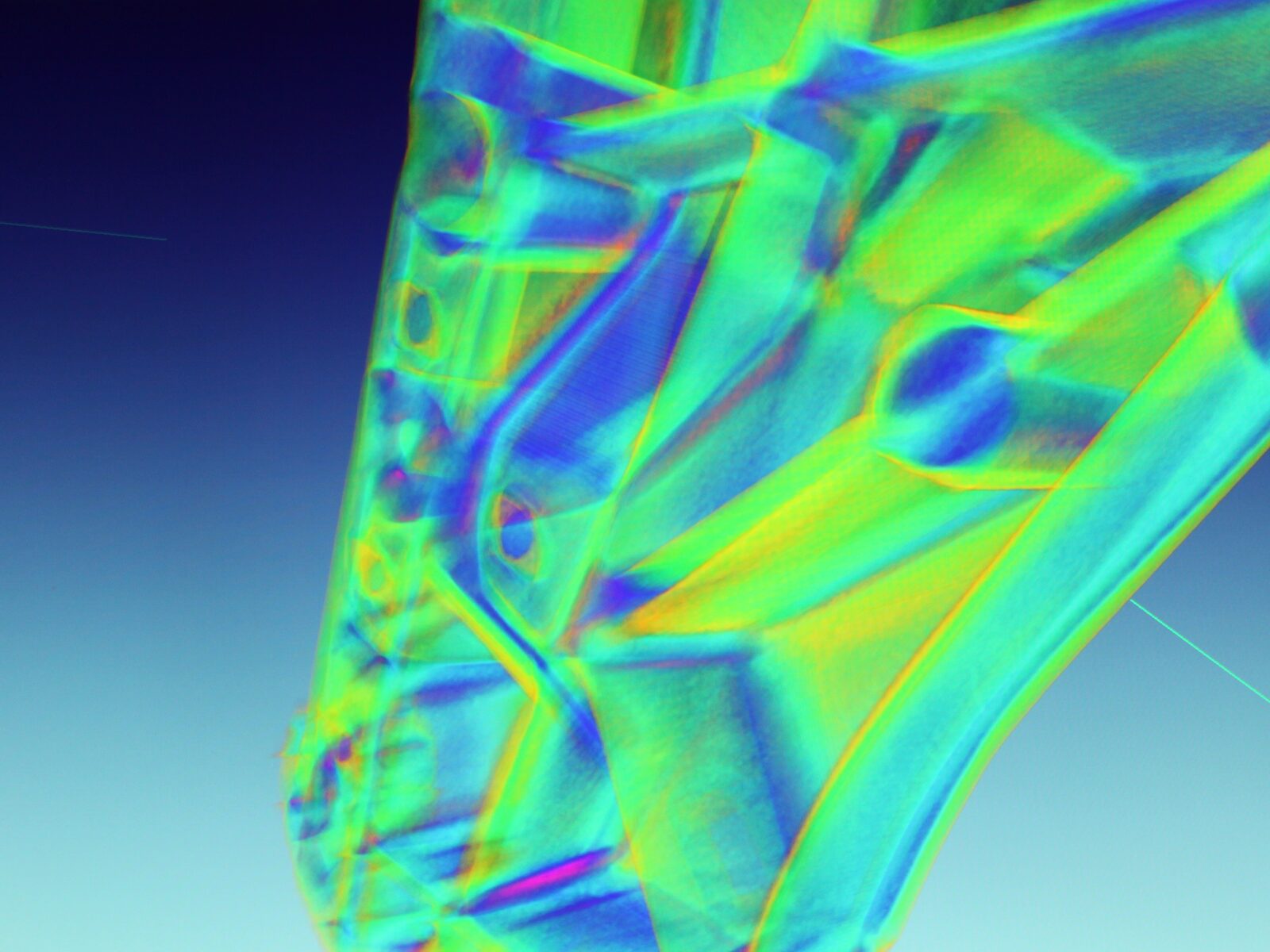

The richness of that model’s source data, for instance, allows technicians to take precise measurements of the subject’s every surface, both exterior and interior. Comparing the scanned model against the part’s CAD file allows them to easily illustrate the part’s compliance with its design specifications by representing its surface areas in different colors based on whether their measurements fall within the range of tolerance given in its design document. These measuring capabilities lend themselves well to applications that typically require rigorous metrology methods, such as first article inspections and reverse engineering projects.

Nondestructive Testing

Furthermore, the X-ray aspect of CT scanning makes it a superior imaging method for certain applications. It provides a greater amount and higher quality of data than most other nondestructive testing methods — including traditional radiography. The amount of reference data that makes up the 3D model allows technicians to detect microscopic flaws in the part’s structure, such as cracks, porosity and voids, and our advanced metrology software lets them measure these flaws volumetrically. With this level of detail, they can easily measure the thickness of both the outer coating and the base material for compliance Additionally, because technicians do not have to alter the part in any way (e.g., cutting it in half, which can cause its structure to deform) to get measurements on its interior, CT scanning has become the method of choice when assessing additively manufactured parts. Such components can have complex shapes and internal features that other testing methods cannot handle. For these reasons, CT represents an incomparable tool for nondestructively identifying flaws for quality assurance purposes.

Forensic Investigations

The rich models produced through CT scanning also serve a function in legal proceedings. Scanning pieces of evidence, such as failed parts suspected to have caused an accident, can offer investigators several benefits. The scanning process is quick and nontactile, which frees the evidence for physical storage elsewhere and eliminates the possibility of it being compromised during analysis. ATS maintains a copy of the 3D model generated in the scanning process as a back-up to the original part and can make that file available to investigators, lawyers, and other relevant parties upon request.

Engineering

Finally, CT scanning can help with redesigning a given part. Based on the data each scan produces, ATS technicians can conduct simulations of the stresses and strains expected to act on the part in its intended service conditions. Doing so can reveal design flaws or other considerations which may require a part to be reformulated. If relevant, our CT technicians can convert the CAD document so that our engineers may perform a full finite element analysis on the part. This is what ATS means when we say versatility; its ability to provide all the above utility in a variety of applications for the effort of completing a single scan makes computed tomography an efficient and valuable method of analyzing parts and assemblies.

Our CT Equipment and Scanning Capabilities

A group of talented technicians staff ATS’ CT inspection labs. These specialists provide our clients with the precise data and high-resolution models they need to perfect their product by drawing on their experience using the following instrumentation:

- Zeiss Metrotom 1500, with a 225kV micro-focus

- Chamber fits specimens up to 11.75 in (300mm) in diameter x 23.6 in (600mm) high. 50 kg (110 lb) weight limit.

- Northstar Imaging X5000

- Multi-Axis Manipulator (x, z, tilt, rotation), capable of supporting max 250 lb

- Resolution of manipulator angle is 0.001°

- Capture elongated subjects unable to fit within a single exposure by scanning with a spiral acquisition

- Minifocus 450kV X-ray projector (0.016” Focal spot at 3mA)

- Dual energy capability with 225kV Microfocus X-ray Machine

- Can achieve focal size as low as 0.0002” (based on voltage)

Applied Technical Services: Trusted Computed Tomography Provider

Since our founding in 1967, Applied Technical Services has offered testing, consulting engineering, and inspection capabilities of exceptional quality. In the intervening 50+ years, our company has enjoyed phenomenal growth. What started as a team of three engineers doing small jobs for local businesses out of our founder’s basement has since exploded into a multidisciplinary firm that employs nearly a thousand technicians, investigators, inspectors, scientists, chemists, calibrators, and Professional Engineers who serve clients operating in countries all around the world. Of the many we serve, the following industries most benefit from ATS’ expertise in providing 3D part scanning services:

- Renewable Energy

- Additive Manufacturing

- Nuclear

- Automotive

- Power Generation

- Aerospace/Aircraft

- Defense/Military

- Healthcare/Medical

- Conventional Manufacturing

- Insurance/Legal

Quality is Our Priority

ATS values quality as one of our guiding principles. As such, we ensure our skilled CT technicians perform all part scanning services in compliance with our ISO 9001:2015-registered quality management system. By doing so, they maintain our commitment to excellence and ensure our clients receive the quality of service that they deserve. Furthermore, we continually improve the quality of the services we provide by maintaining a program that follows the internationally recognized standard of effective quality management. The policies we uphold to ensure our clients enjoy the best experience possible while working with ATS include:

- Testing personnel return clear, accurate, detailed results within a short turnaround time

- Customer service ambassadors receive customers reaching out regarding the status or results of their testing

- These relationship experts direct clients to the appropriate testing specialist and facilitate contact

- Technicians and other lab personnel remain accessible to client outreach, responsive to their needs, and engaged while helping them find a solution to their problem

If your company needs premier 3D part scanning services to verify a component’s dimensions, detect its flaws, preserve it for evidence, or formulate its service conditions, contact ATS today about our CT capabilities — We take a closer look!