- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Computed Tomography

Services

ATS understands the importance of testing

equipment parts to verify conformance to

specifications and evaluate quality. ATS

can provide you with premier computed

tomography services, offering analysis

of critical equipment parts with our industry-

leading computed tomography tools.

equipment parts to verify conformance to

specifications and evaluate quality. ATS

can provide you with premier computed

tomography services, offering analysis

of critical equipment parts with our industry-

leading computed tomography tools.

Computed Tomography Services

ATS understands the importance of testing equipment parts to verify

conformance to specifications and evaluate quality. ATS can provide

you with premier computed tomography services, offering analysis of

critical equipment parts with our industry-leading computed tomography

tools.

conformance to specifications and evaluate quality. ATS can provide

you with premier computed tomography services, offering analysis of

critical equipment parts with our industry-leading computed tomography

tools.

Computed Tomography Services

ATS understands the importance of testing equipment parts to verify conformance to specifications and evaluate quality. ATS can provide you with premier computed tomography services, offering analysis of critical equipment parts with our industry-leading computed tomography tools.

Major Applications

Industries that love CT

- Aerospace

- Automotive

- Communications

- Consumer Products

- Defense

- Healthcare

- Insurance / Legal

- Manufacturing

- Nuclear

- Power Generation

Previous

Next

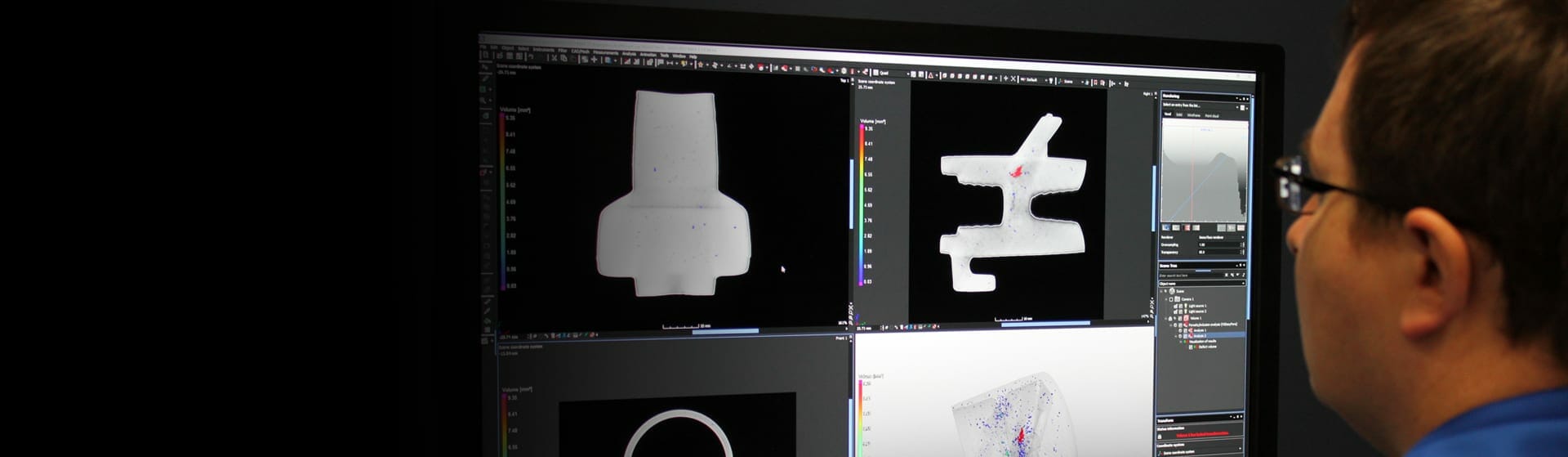

State-of-the-art Equipment

ATS’ powerful imaging equipment enables our CT scanning experts to do what they do best — see what’s going on. Our Northstar Imaging X5000 offers multi-axis manipulation and spiral acquisition schemes to complete scans of those unwieldy elongated samples in a single exposure. For some of the most detailed imaging available, our Zeiss Metrotom 1500 uses a 225kV micro-focus to capture stunningly precise scans for clients with a need for greater fidelity. We maintain an annual A2LA calibration schedule because ATS cares about quality and prides ourselves on providing the highest quality imaging that we possibly can.

Further Applications

Get a better idea of the ways we can use CT to help you below:

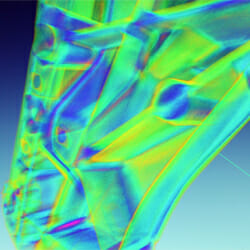

FEA

ATS technicians can send our CT-generated models to our in-house Professional Engineers for FEA to simulate structural, fluid, and thermal stresses

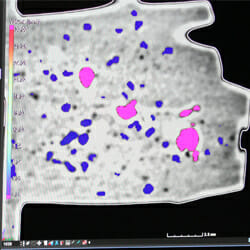

Porosity

Our CT program allows us to not only detect porosity and voids, but highlight, measure, and sort them according to size and location