- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Avionics Lab: ATS The dimensional inspection and repair of avionic components are vital in retaining the safety of aircraft. Many aviation manufacturer standards are recognized by our experts during the Calibration process of ADF antennas, Altimeters, Angle Position Indicators, Distance Measuring Equipment (DME) Test Systems, Nav/Comm Ramp Test Sets, ATC ATCRBS Ramp Test Sets, Mode S/TCAS Ramp Test Sets, Transponders and Signal Generators.

Related Links: Avionic Cal Labs | Avionics Calibration

Computed Tomography (CT): Applied Technical Services offers Computer Tomography Services for clients looking to analyze and verify the quality of their products. The demand for Computed Tomography has increased in recent years due to advancements in technology, allowing CT scans to provide an efficient, nondestructive method of testing. Utilizing our three-dimensional CT scans, our Tomography experts are able to measure interior dimensions and discover hidden design flaws. Our CT Lab contains a Zeiss Metrotom 1500, 225kV micro-focus capable of analysis volume up to 300 mm (11.75 in) diameter X 600 mm (23.6 in) high and a 50 kg (110 lb) weight limit as well as a Northstar Imaging X5000 capable of a resolution of manipulator angle to 0.001 of a degree. ATS’ advanced Tomography machines place us an industry leader.

Related Links: 3-D CT Scans | CT Inspections

Dimensional Lab: Applied Technical Services use of modern technology, multiple automated Coordinate Measuring Machines (CMM’s), and advanced software such as PC-DMIS CAD++ make us one of the most comprehensive Dimensional Inspection service providers in our industry. From simple linear measurements to the most complex and accurate measurements imaginable, our CMM Inspections and CMM Programming capabilities are unsurpassed. Along with noncontact measurement techniques utilizing the Vision System and optical comparators, ATS’s virtually unlimited Dimensional Inspection Lab is equipped with three Ultra High Accuracy CMM’s, a 7-10-7, a 9-15-8 and a 12-30-10. Housed in a controlled environment, our Lab is highly recognized and committed to meeting our customers’ needs such as, CAD Model Inspections, 100% Dimensional Layouts, First Article Inspections, PPAP Reports, Process Capability Studies / CpK Studies, Inspection Gage and Fixture Calibration Certifications and Reverse Engineering projects. Most inspections are performed in accordance with ASME Y14.5M – 2009.

Related Links: First Article | Reverse Engineering | Surface Roughness | Surface Plates

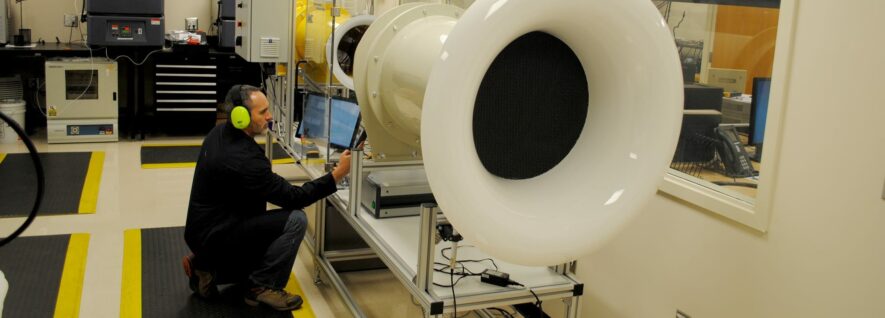

Electrical Lab: Using certified reference materials, ATS has the capability of measuring even the most accurate multi-function device. We provide calibration of both hand-held and bench top multimeters for the following functions: AC/DC Voltage, AC/DC Current, Resistance, capacitance, inductance, thermocouple, and power. Some of the electrical instruments we have the capability to calibrate are; Capacitance Meters; Clamp-On Meters and Probes; Current Shunts; Decade Boxes; ESD Check Systems; Frequency Counters and Generators; Fuel Quantity Test Sets; Gauss Meters; Heat Sealers; High Voltage Test Sets; High Current Test Sets; High Voltage Meters; Hi-pot Testers; Insulation Testers; Magnetic Particle Machines; Meggers; Mega Ohm Meters; Micro Ohm Meters; Multichannel Recorders and Data Loggers; Multifunction Calibrators; Handheld and Benchtop Multimeters; Network Analyzers; Oscilloscopes; Panel Meters, pH Meters; Power Meters; Power Supplies; Process Calibrators; Pyrometers; Rheometers; Resistors; Safety Analyzers; Scope Meters; Signal Generators; Spectrum Analyzers; Stopwatches; Stroboscopes; Tachometers; Watt Meters; Welders and Wire Length Meters.

Related Links: Hi-pot Tester | Insulation Testers | Data Loggers | Multimeters | Oscilloscopes

Field Services: Applied Technical Services has a wide range of capabilities to perform onsite calibration services on your measuring tools and testing equipment. Traveling to your facility and servicing your equipment not only reduces the amount of downtime required to perform the calibrations but also allows us to calibrate large items such as Compression and Tensile Test Machines, Hardness Testers, Surface Plates, Optical Comparators and Environmental Chambers that are too large to be sent to a laboratory for calibration. We specialize in the Automotive, Aerospace, Medical Equipment and General Manufacturing Industries, to name a few.

Related Links: Hardness Testers | Surface Plates | Surface Roughness Testers | Environmental Chambers

Mechanical Lab: Servicing tools such as pressure and vacuum gauges, cable tensiometers, and torque wrenches, our Mechanical Calibrations team can verify the accuracy of your pressure and torque equipment. Some of the regularly calibrated equipment include, Outside, Inside, Depth and Bore Micrometers; Calipers; Height Gages; Dial, Digital and Test Indicators; Length Scales, Pi-Tapes, Rulers and Tape Measures; Footage Counters; Protractors; Force Gages; Accelerometers; Manometers; Surface Finish Testers; Weight Scales; Platform Scales; Triple Beam Scales and Analytical Balances.

Related Links: Calipers | Pressure Gages | Force Gages | Accelerometers | Torque Wrenches

On-Site CMM Services: Applied Technical Services offers fully comprehensive On-Site CMM Services for any of your Coordinate Measurement Machine needs. Our Dimensional Inspectors have the capability to conduct a wide range of CMM services such as First Article Inspections, PPAP Reports, Process Capability Studies / CpK Studies, Inspection Gage and Fixture Calibration Certificates and Reverse Engineering projects. We also offer training of essential CMM principles such as PC-DMIS Training, GD&T and Cartesian Dimension Callouts, Probe Set-ups, Proper Control of a Part with Alignments, Understanding of the 6 Degrees of Freedom, How to Level, Rotate, and Origin a Part with Datum Features, Measurement Plans, Caliper and Gauge Equipment, Multiple Method Based Verification of Data, Custom Reporting of Dimensional Data, Safely powering the Controller and Computer, and Maintenance and A2LA Guidance. Our team performs most Dimensional Inspections in accordance to ASME Y14.5M – 2009.

Related Links: PC-DMIS Training | On-site Services | Programming Training | Measurement Services

Standards Lab: ATS’ Standards Lab is environmentally-controlled for high precision measurement capabilities. The lab is controlled to 68°F within a span of +/-1.0°F and humidity controlled at 30-55% R.H. The lab also has isolation joints in the flooring to reduce any vibration effects. All gages are cleaned prior to testing and are placed in the Standards Lab to achieve temperature stabilization for a minimum of 24 hours. ATS has the capability to perform calibration on a wide range of Setting Standards and Working Gages with the ability to calibrate classes XXX, XX, X, Y, Z, and ZZ toolmakers tolerances as well as customer’s tolerances. Internal measurements are limited to 12 inches and external measurements to 13 inches.

Related Links: Weight Calibration | Adjustable Threads | Gage Block | Gage Calibration

Thermal Lab: ATS provides complete calibration services for all your thermometry needs. From ITS-90 Fixed point cells to bench top thermometer displays, to hand-held devices, we can offer the best calibration solution for the strictest requirements. ATS offers world class temperature probe calibrations employing state-of-the-art equipment and methodologies including temperature baths, ice point references, block calibrators, and standard and high accuracy thermometers. We provide accredited calibrations on various types of temperature devices including glass thermometers, thermocouples, RTD thermometers, temperature recorders, dial, surface, infrared and digital thermometers.

Related Links: Thermometers | Thermocouples | Chart Recorders | Humidity Calibration | Anemometers

Equipment Repair Services: Applied Technical Services provides equipment repair services through ENI Labs, a member of the ATS company family. We perform equipment repairs on products made by Allen Bradley, Bosch, CENTRALP, Danfoss, Siemens, as well as other manufacturers. Our highly trained technicians perform guaranteed repairs on servo motors, circuit boards, controllers, displays, motors, drives, power supplies, monitors, operator interfaces, touch panels, X-ray units, panels, and several other types of equipment, components, and parts.