ATS Advances IC Testing

ATS recently acquired a new Ion Chromatography (IC) unit and accompanying software to improve throughput and create more efficiencies for our clients. IC analysis is not new to ATS’s scope of testing capabilities – our team of skilled analysts has provided IC analysis to our clients for 25+ years. During that time, ATS has worked with various industries, including nuclear and electronics, to identify corrosion and/or contamination on parts by utilizing IC analysis along with other analytical capabilities. IC analysis can also be used as part of a corrosion prevention strategy. Finished components can be tested for residual anions to ensure the production process limits the amount of potentially corrosive species. Methods frequently used for analysis are ASTM D4327 and IPC-TM-650. Please contact ATS today with your IC testing needs!

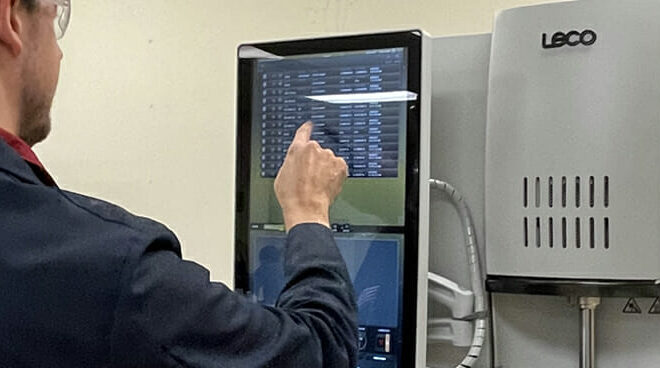

LECO Testing Growth at ATS

ATS continues to invest in new analytical instrumentation to meet the demands of our valued clients. In May of 2022 ATS acquired 2 new additional LECO instruments, bringing the total to 4 LECO analyzers in our headquarters in Marietta, GA. Our new LECO combustion analyzer is equipped with an autosampler to increase efficiencies. LECO analysis is used to determine the content of carbon, hydrogen, nitrogen, oxygen, and sulfur in metallic samples. With our new LECO ONH 836 unit, the chemist is able to test titanium samples at a faster rate due to the high-capacity chiller unit that accompanies the Instrument.

Carbon and sulfur in metallic samples are commonly analyzed by the LECO instrumentation, and so ATS has also added this capability to the Phoenix, AZ location. Typical industries served include automotive, aerospace, medical, and additive manufacturing (including printer and powder manufacturing). ATS routinely works with our clients to develop standards for various industries along with testing to the following established methodologies: ASTM E1019, ASTM E1941, ASTM E1409, ASTM E1447, and ASTM E2575.

Electrical Testing Accreditation at ATS

With the introduction of our Marietta, GA location’s electromagnetic interference and compatibility testing lab in October of 2021, ATS continues to expand our testing and analysis offerings to include new, highly advanced electrical testing capabilities to meet the needs of our clients. In addition to Dielectric Strength, Insulation Resistance, Contact Resistance, Conducted and Radiated Emission, Conducted Susceptibility, and Power Variation testing, ATS is now accredited by the A2LA in MIL-STD-461G Radiated Susceptibility RS101 and RS103 testing. Our highly skilled electrical testing experts apply years of experience and utilize state-of-the-art equipment to ensure the highest level of accuracy in our EMI and EMC lab, performing comprehensive electrical testing for a wide range of industries including aerospace, automotive, aviation, consumer product testing, and electronics. Get in touch with us today for more information regarding our EMI and EMC testing services.

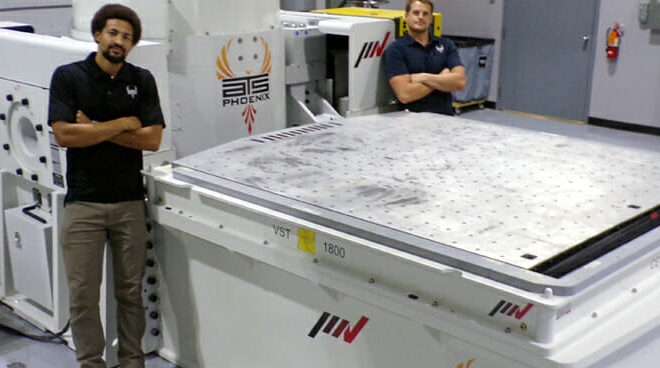

ATS is pleased to announce the delivery of the IMV K200 Electrodynamic Shaker

This shaker unit allows the team at ATS Phoenix, AZ lab to be able to venture further into industries that require larger, more powerful shakers. It weighs in at 76,000 pounds and features a force rating of 45,000 lbf, a 70”x70” slip table, a 48” x 48” expander head and up to a 3” pk-pk stroke. The unit can handle payloads up to 6,600 pounds and control at frequencies up to 2000 Hz.

Projects currently utilizing the new shaker unit include testing of EV batteries and satellites.