- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Sine-on-Random Vibration Testing

Applied Technical Services performs sine-on-random vibration testing to most accurately simulate the types of forces that clients’ samples must endure in their intended service environment.

Vibrations, the wavelike propagation of an applied force that causes particles to oscillate around their point of equilibrium, can cause a progressive type of damage to materials over time. This damage is called fatigue, and it can produce cracks that undermine the structural integrity of a component or subassembly. Such a defect can cause major failure in a final assembly: e.g., if one of the bolts holding a vehicle’s wheel to the rest of the car were to break months after the driver runs over a pothole initiating a crack, it could cause a traffic accident. Unanticipated vibrations can also cause electronic components to dislodge and thus fail to perform. This, too, can prove devastating in highly demanding service environments: e.g., if the pilot’s console fails mid-flight due to turbulent weather, then the safety of everyone on board is at risk.

A variety of manufacturers send samples to a qualified vibration testing provider, such as ATS, because our services can help them ensure their materials and components perform as expected and meet their quality requirements.

The Purpose Behind Sine-on-Random Vibration Testing

Our environmental testing division performs several disciplines of vibration testing. Applying a sinusoidal vibration scheme allows them to find a sample’s resonance point, exploit it to induce fatigue, and observe prevalent failure modes. Alternatively, using a random vibration regimen serves to expose samples to vibrations from a range of frequencies relevant to its intended service environment. While both methods serve a purpose, neither the idealized sinusoidal vibration plan nor the chaotic random vibration plan quite captures the realities of actual service conditions. Sine-on-random vibration testing affords our technicians the benefits of both.

ATS applies the sine-on-random method of vibration testing to achieve the closest approximation of what a given sample must endure in its intended service environment. While randomized schemes ignore vibrations of any wavelength or amplitude that lie outside its scope and disregard any possibility of uniformity, using a sine-on-vibration regimen allows our technicians to incorporate these features seamlessly into their simulations. They apply outlier sinusoidal vibrations against a background of random noise vibrations — perfect for simulating the vibrations experienced by the rotor grip as a helicopter flies through the skies or those faced by an engine as it pushes a truck down the road.

Our Vibration Testing Capabilities

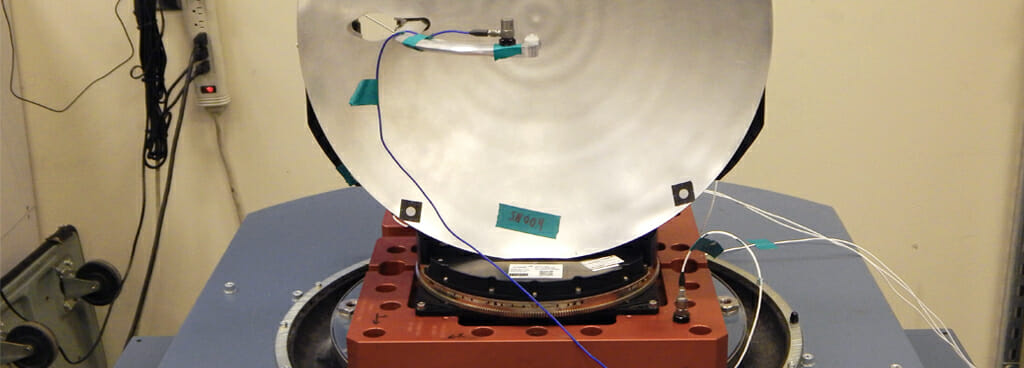

Anyone familiar with vibration testing knows that securing the sample to the shaker table represents a fundamental concern. Ensuring that fixtures fit the sample and do not share a resonant frequency with the scope of vibrations to be applied in testing can mean the difference between useful data and faulty results. ATS comes equipped in this arena, as we fabricate all our own fixtures in our machine shop. Because we perform this function in-house, we can both ensure the fixtures are appropriate for the sample, verifying a compatible fit and appropriate resonant frequency, and reduce the cost to the client by avoiding outsourcing.

Our vibration testing lab houses the advanced equipment our experts use to perform this method. Their top-of-the-line electrodynamic shaker tables allow ATS technicians to precisely apply a range of vibrations: they can achieve frequencies anywhere from 5 to 2,000Hz and as much as 12,000 pounds of force. When relevant to the scope of work, our attachable AGREE environmental chambers enable these specialists to introduce temperature variations as well for combined analysis.

We offer sine-on-random vibration testing to the following specifications, for which we maintain ISO 17025 accreditation through the A2LA:

Typical Specifications Include:

Since our founding in 1967, Applied Technical Services has provided for the needs of our clientele through the expertise of our personnel. Over our 50+ years in business, we have grown tremendously from a trio of engineers into a multidisciplinary firm offering testing, consulting engineering, and inspection services, among others. We now employ over 1,000 technicians, scientists, chemists, investigators, inspectors, calibrators, trainers, and Professional Engineers to serve the varied needs of clients operating around the globe. Although ATS serves many more with our greater collection of environmental testing services, the industries most benefit from our capacity as a vibration testing provider include the following:

- Aerospace / Aviation

- Communications

- Healthcare / Medical

- Defense / Military

- Insurance / Legal

- Automotive

- Manufacturing

If your company needs sine-on-random vibration testing services, come to the experts. Contact ATS today for a free quote — We take a closer look!

Request Form

"*" indicates required fields