- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

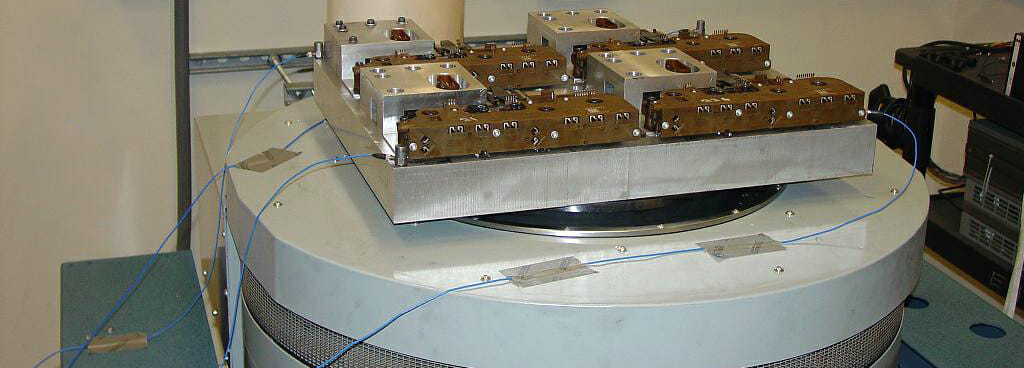

Vibration Shock Testing Services

ATS performs vibration shock testing to assess a subject’s resilience and identify potential structural flaws that could lead to malfunction or failure.

Vibration Shock Testing at ATS

Applied Technical Services conducts vibration testing by exposing a device to various types and levels of vibration. ATS replicates transit conditions, standard operating conditions, and installation conditions during testing to ensure the subject’s ability to function throughout all phases of its life cycle. The most effective testing method is determined by the subject’s intended use and functionality.

Shock Testing Methods

ATS performs different methods of shock testing, including but not limited to:

- Functional Shock (MIL-STD 810, RTCA DO 160)

- Fragility

- Bench Handling

- Random on Random

- Transit Drop

- Material-to-be-Packaged

- Crash Hazard Shock

Potential Shock Testing Outcomes

Shock testing allows ATS to identify several different types of flaws, including structural and mechanical failures, connection and material failures, variations in electrostatic and magnetic fields, changes in dielectric strength, friction between parts, loss of insulation resistance, and failure in electronic components such as circuit cards.

Vibration Testing Standards and Specifications

Applied Technical Services conducts vibration testing in accordance with several different standards, including but not limited to:

- MIL-STD 810G Method 514.6

- IEC 60068-2-27

- IEC 60068-2-6

- IEC 60068-2-64

- IEEE 344

- RTCA-DO-160 S8: Vibration

Applied Technical Services

Applied Technical Services is proud to be the preferred industrial testing service provider of many of the nation’s most prominent construction, nuclear, automotive, aerospace, and military companies and manufacturers. ATS strives to achieve the highest level of customer satisfaction on every project, maximizing the value of our testing services through use of innovative technologies to reduce client costs. ATS is ISO 9001 certified and holds several ISO 17025 accreditations by the A2LA. Trust the proven experts at ATS with over five decades of experience and contact us today to schedule your next vibration shock testing services.

Request Form

"*" indicates required fields