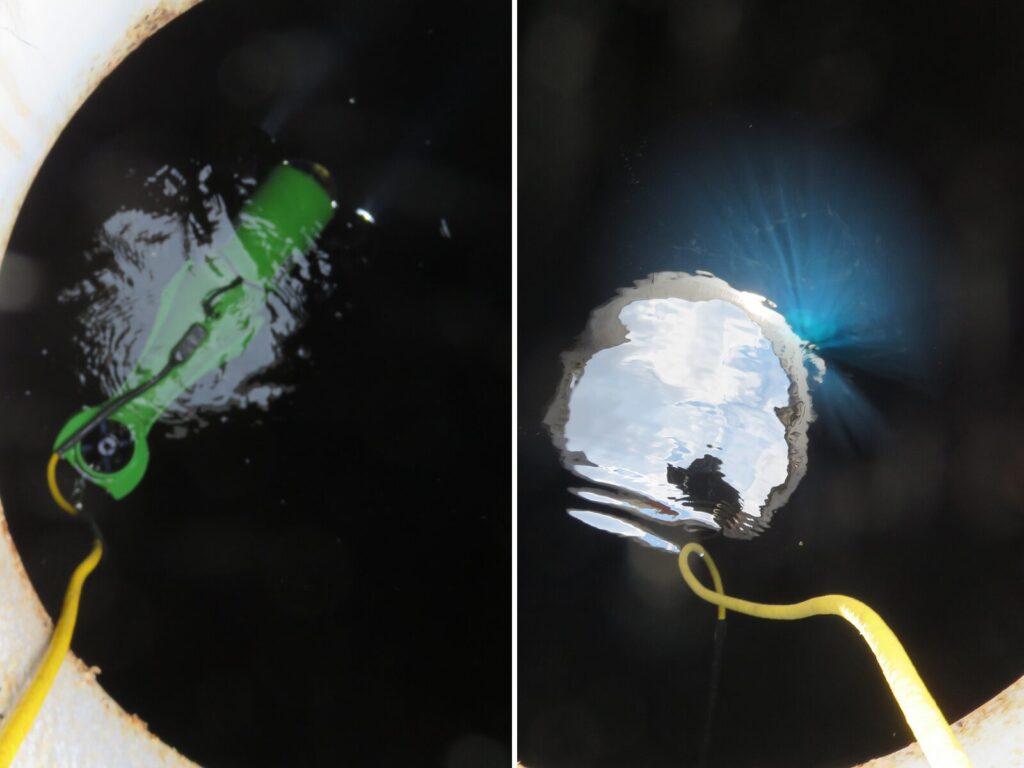

Applied Technical Services offers submersible ROV inspection services for clients who need equipment condition assessments. ROV’s (remotely operated vehicles) are unmanned robots that technicians can use to conduct visual inspections on client equipment. Our submersible ROV’s allow us to evaluate water storage tanks and other equipment according to the following standards:

- AWWA D103 for Bolted Steel Water Storage Tanks

- AWWA D100 for Welded Carbon Steel Water Storage Tanks

- API 653 for Tanks

- NFPA 25 for Water-Based Fire Protection Systems

ROV technology can eliminate the need for confined space entry and expensive diving operations. ATS experts can inspect all a tank’s internal services without taking any safety risks.

ROV Experts

Our certified, licensed, highly trained personnel can offer true condition assessments for client equipment. We can assess all aspects of the equipment’s health, including floor plates, sidewalls, ladders, roof plates, hatches, and pipes, using remotely controlled inspection equipment. ROVs also allow us to conduct inspections while the equipment remains in service. ATS’ licensed Professional Engineers and certified API inspectors can collect thorough, accurate data that allows asset owners to budget for any major repairs, plan future shutdowns, and schedule subsequent inspections. As third-party tank consultants, we have the equipment and expertise necessary to assist clients with all their fixed asset needs.

Consistent Inspection Programs

Keeping consistent inspection programs lowers risks of containment loss and helps maintain a safe environment. Postponing inspections beyond the recommended timeframe can lead to issues with corrosion, contamination, excessive debris, coating failure, and sediments. Corrosion, a leading cause of fixed equipment failure, poses a greater risk the longer it goes unchecked.

Routine inspections with ATS keep fixed equipment running properly. We can identify potential issues and damaged mechanisms early, evaluating all aspects of equipment health from weld quality to standard compliance. Our engineers calculate repair plans, giving repair contractors a detailed scope of any necessary repairs before repairs begin. ATS helps clients minimize downtime while maximizing our inspection value through practical condition assessments. These assessments help clients understand their equipment’s health in detail and allow them to prioritize their assets’ needs.

Mechanical Integrity Evaluations

ATS’ mechanical integrity programs are an integral part of monitoring fixed equipment conditions and process safety management (PSM). Whether our clients need ROV inspections for tanks or fitness for service assessments for power piping, we can help assess or develop a comprehensive mechanical integrity program that suits their particular needs. Our programs typically address the following:

- Program management and ownership

- Methods and frequency of inspection

- Applicable standards

- Jurisdictional regulations

ATS offers mechanical integrity evaluations for tanks, pipes, pressure vessels, and other related equipment. We check for numerous issues, including internal and external corrosion, flow-accelerated corrosion, corrosion under insulation, cracking, erosion, fatigue, and manufacturing flaws.

ROV technology allows our inspections to be more cost-effective and detailed in documentation. We can evaluate essential equipment such as fire water storage tanks without any water loss, permitting the equipment to sustain essential functions. We also offer several other methods for inspecting system health without jeopardizing the equipment’s integrity, such as bubble leak testing, magnetic particle testing, ultrasonic thickness testing, penetrant testing, and radiographic testing. Our experts can help determine which services are best for each client’s needs.

Outstanding Service

Applied Technical Services has dedicated decades toward providing the best possible testing and inspection services. Since our founding in 1967, we have continuously strived to improve our range of services and advance our commitment to customer service. Our wide array of mechanical integrity services benefits numerous industries, including:

- Oil and gas

- Construction

- Industrial

- Nuclear

- Energy

- Chemical

- Government

- Pharmaceuticals

- Commercial Properties

- Pulp and paper

- Military

- Manufacturing

Our experts focus on safety, accurate testing, detailed reporting, and quick turnarounds. We hold ourselves accountable to our clients through our strict ISO 9001:2015 registered quality management system. We facilitate contact with clients throughout the inspection process so they can make informed decisions with regard to their equipment. Our customer service ambassadors are responsive to questions about testing or data, connecting clients to the most relevant expert available who can help with their inquiries.

If you need an ROV inspection, contact ATS today for a free quote. We take a closer look!