Applied Technical Services provides XRD surface analysis services to assist clients with material identification for several applications, from reverse engineering to corrosion failure analysis. Our experts in metallurgy conduct XRD testing in compliance with the ASTM D934 standard.

Surface X-Ray Diffraction

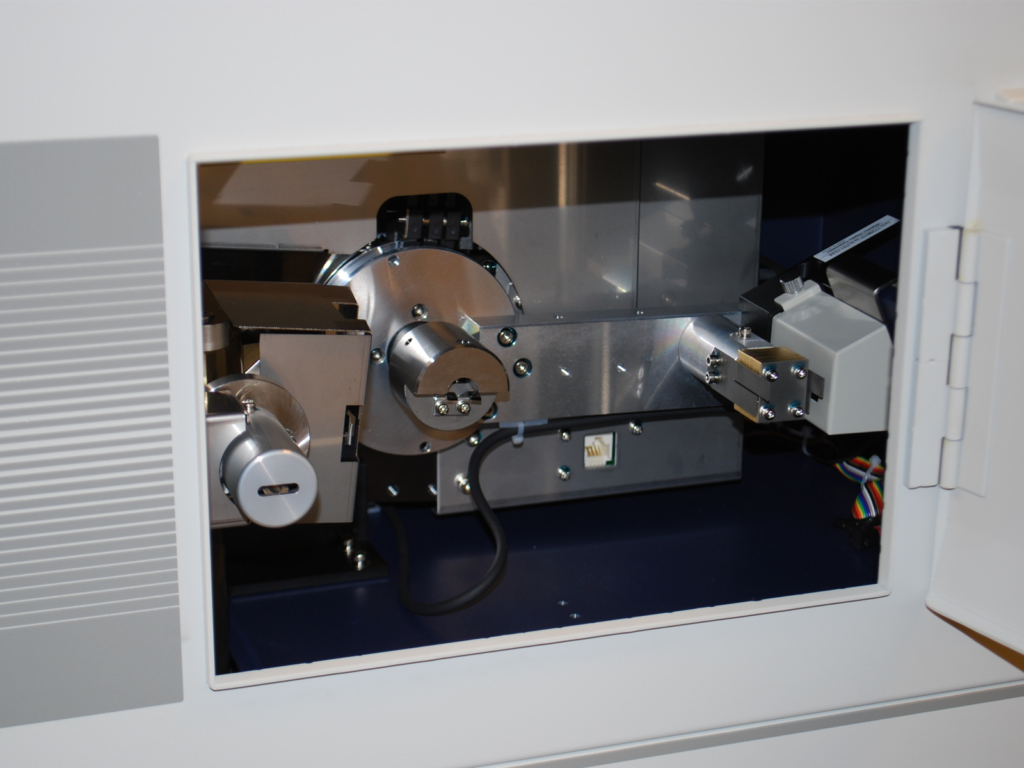

XRD works by radiating monochromatic x-rays through the sample from different angles. The randomly oriented crystalline structures within the sample scatter the x-rays, creating a diffraction pattern that is unique to the sample material. We then compare the pattern to the ICDD (International Centre for Diffraction Data) diffraction pattern database, measuring the data against hundreds of thousands of references to determine the exact compounds comprising the sample.

Benefits of XRD

Crystal structures directly affect a material’s properties and functionality. XRD helps clients to determine their sample’s qualities with precision. ATS conducts XRD testing to assist clients with contaminant identification, metallurgical phase verification, revere engineering for coatings, research and development, material production, and corrosion analysis. X-ray diffraction is a rapid testing method that can analyze metallurgical mounts, powder samples, and certain coatings.

ATS’ Metallurgical Capabilities

Our metallurgy lab offers a wide variety of testing methods to assist clients with material identification, failure analysis, and litigation support. ATS testing experts bring experience and knowledge to all our testing services, adding quality to the work. We offer several types of metallurgical testing, such as:

- Rockwell, Vickers, Knoop, and Brinell Hardness Testing

- Intergranular Corrosion Testing

- Energy Dispersive Spectroscopy (EDS)

- Scanning Electron Microscopy (SEM)

- Metallography

ATS Services

Applied Technical Services has offered dependable inspection and testing services since 1967. Our staff includes metallurgists, professional engineers, inspectors, technicians, chemists, and calibrators who can assist commercial and industrial clients from countries around the world. We serve several industries, including:

- Aerospace

- Foundries

- Manufacturing

- Automotive

- Insurance and Legal

- Chemical

- Consumer Products

- Oil and Gas

At ATS, quality is a core value that informs all our testing services. We work to continuously improve our clients’ experience with us by upholding stringent customer service policies. Our customer service team connects customers directly to subject matter experts who can help with their inquiries. Our experts can answer any questions clients may have throughout the testing process.If you need XRD surface analysis, contact ATS today.