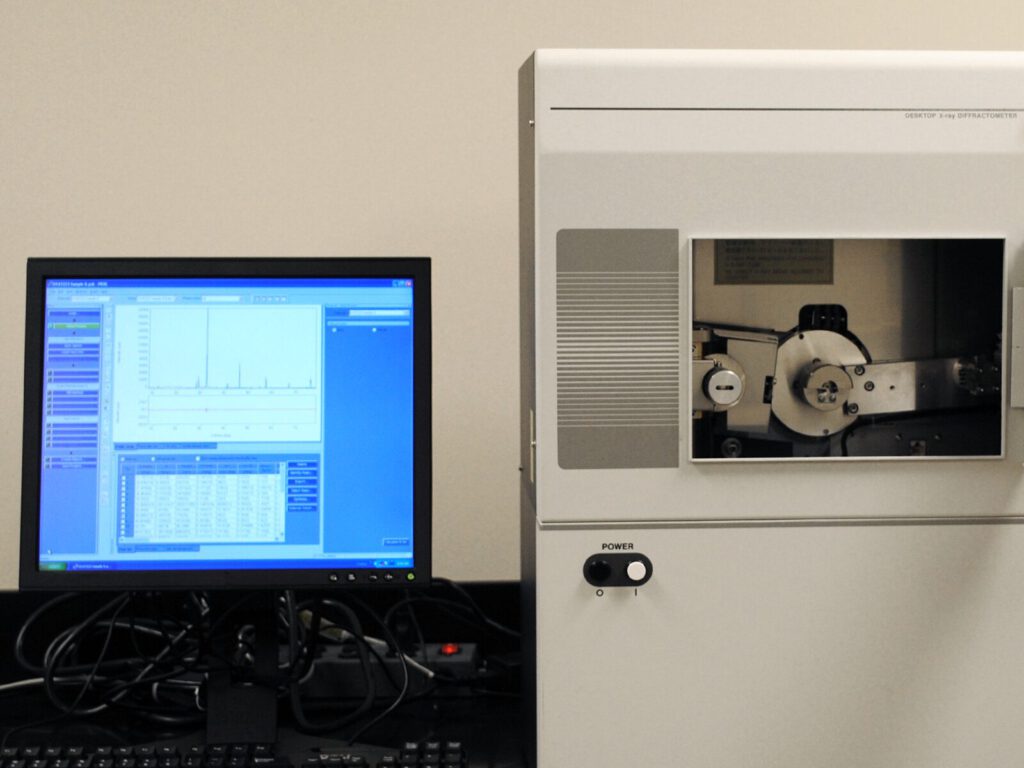

Applied Technical Services offers XRD analysis through our metallurgy laboratory. XRD or x-ray diffraction is an observation method utilized in material identification. This method can be useful in many applications, from corrosion failure analysis to reverse engineering. Our metallurgy experts conduct all XRD analysis testing in accordance with the ASTM D934 standard.

X-Ray Diffraction

XRD analysis, or surface XRD, is a non-destructive observation method used to assess the atomic structure of crystalline materials. XRD works by exposing a material to incident x-rays that excite the crystal atoms, which scatter the angles of the x-ray, allowing them to be measured and evaluated. This phenomenon is known as elastic scattering.

Our technicians compare the diffraction patterns to the diffraction pattern database at the ICDD (International Centre for Diffraction Data), cross-referencing the patterns against a multitude of references to determine the composition of the sample material.

The Benefits of XRD

X-ray diffraction helps clients understand their sample material’s atomic qualities and limitations. This useful method can determine structural properties such as lattice parameters, grain size, epitaxy, strain, preferred orientation, and phase composition. ATS technicians perform XRD analysis to help clients with metallurgic phase verification, research and development, corrosion analysis, contaminant identification, reverse engineering for coatings, and material production.

Accepted Samples

XRD analysis is a versatile method that can analyze powder samples, certain coatings, and metallurgical mounts.

Our Metallurgy Capabilities

Applied Technical Services’ metallurgy laboratory offers a litany of additional services such as failure analysis, litigation support, and material identification. Our team of qualified professionals routinely performs the following metallurgic testing services:

- Scanning Electron Microscopy (SEM)

- Rockwell, Vickers, Knoop, and Brinell Hardness Testing

- Energy Dispersive Spectroscopy (EDS)

- Intergranular Corrosion Testing

- Metallography

Why Choose ATS?

Applied Technical Services has offered top-tier inspections, testing, and engineering consulting for more than 50 years. Client satisfaction is our biggest priority thanks to our corporate management program, registered to ISO 9001:2015. Our customer service team puts clients in touch with qualified professionals that can help find solutions to their inquiries.

To request a free quote, contact Applied Technical Services today! We can take care of all your XRD analysis needs. We Take a Closer Look!