Ash testing, also commonly referred to as ash content analysis, is a hugely important element of research and development for a number of key reasons. A thorough ash test can help determine what percentage of a particular sample includes filler content, which can help determine exactly how a sample will react throughout the course of its life cycle when exposed to normal room temperature.

ATS’ Approach to Ash Testing

At Applied Technical Services, our highly trained team of technicians and chemists use a number of different procedures for all ash testing needs, including industry standards including ASTM D2584 and the latest revision of ASTM D5630. A typical ash test involves taking a known weight of a sample and placing into a specially designed crucible in a muffle furnace, and heating to at least 500 degrees Celsius to burn off the polymer. When the sample has had a chance to cool in a desiccator, the ash residue that remains in the crucible is weighed. Any residue that remains in the crucible after this point is considered to be filler and is expressed as percentage of ash.

Related Services

ATS can also take things to the next level by performing a number of related services after ash testing has been completed, which will vary depending on the exact results of the previous technique.

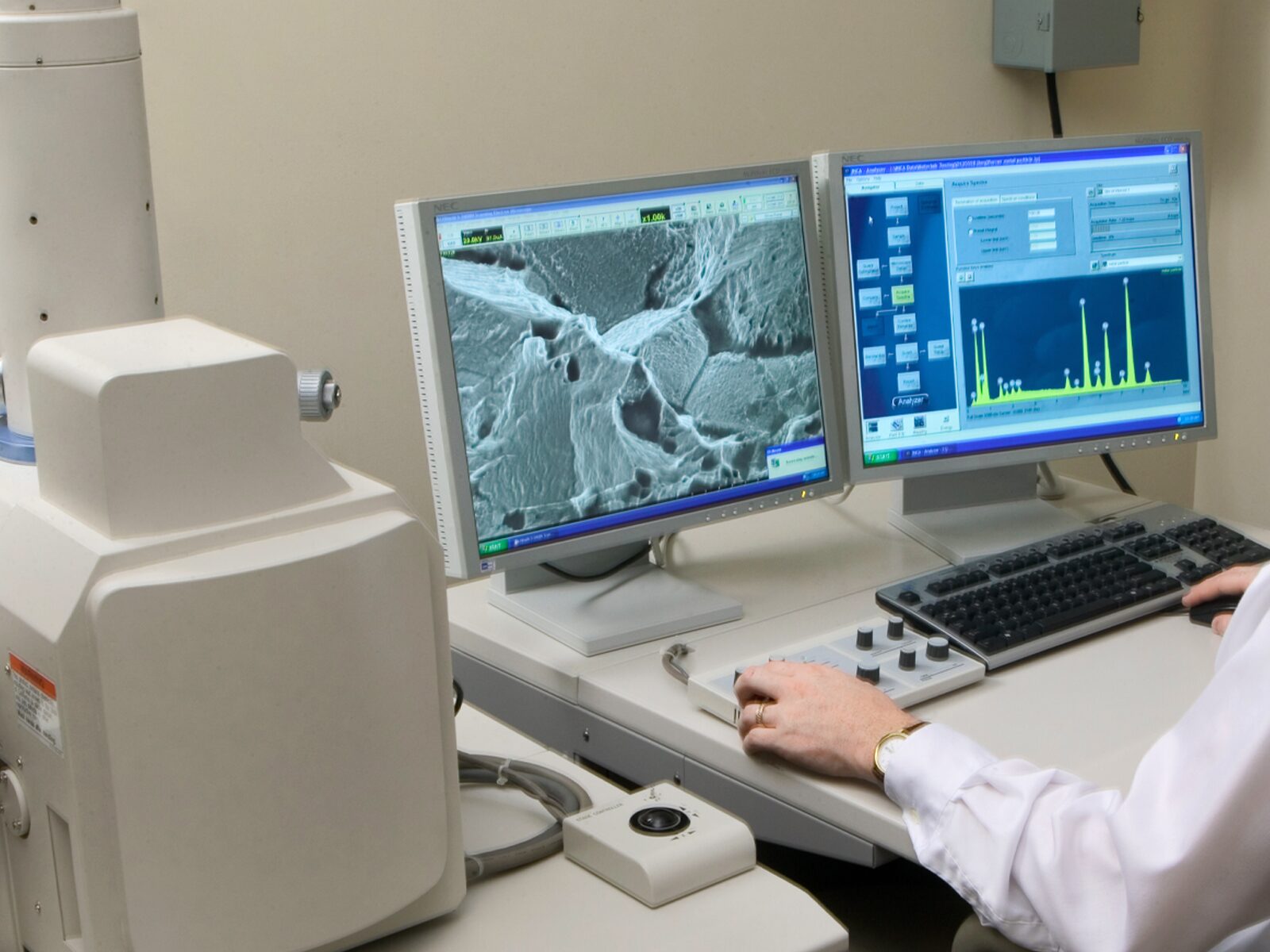

- SEM or XRD analyses can be conducted to properly identify what type of mineral you’re working with, if the remaining ash in the crucible is determined to be mineral based.

- FTIR analysis can often be used to characterize type of fillers such as calcium carbonate, talc, and glass fiber.

At ATS, we provide excellent customer service by offering accurate analysis performed in technically advanced labs at an economical price. In addition to friendly service and quick turnarounds, ATS shows its commitment to quality assurance by holding multiple accreditations and certifications including ISO 9001:2015. If you are looking for ash testing lab, contact Applied Technical Services for accurate and dependable test results.