Remote visual inspection (RVI) is a type of non-destructive testing that uses specialized camera equipment to conduct visual tests on structures and equipment. Technicians use drones, borescopes, and other types of robotic camera systems to remotely access confined spaces, foreign material exclusion zones, and other inaccessible areas. Applied Technical Services’ remote visual inspection services help clients maintain standard compliance and safety with minimal disruptions to productivity.

About the Method

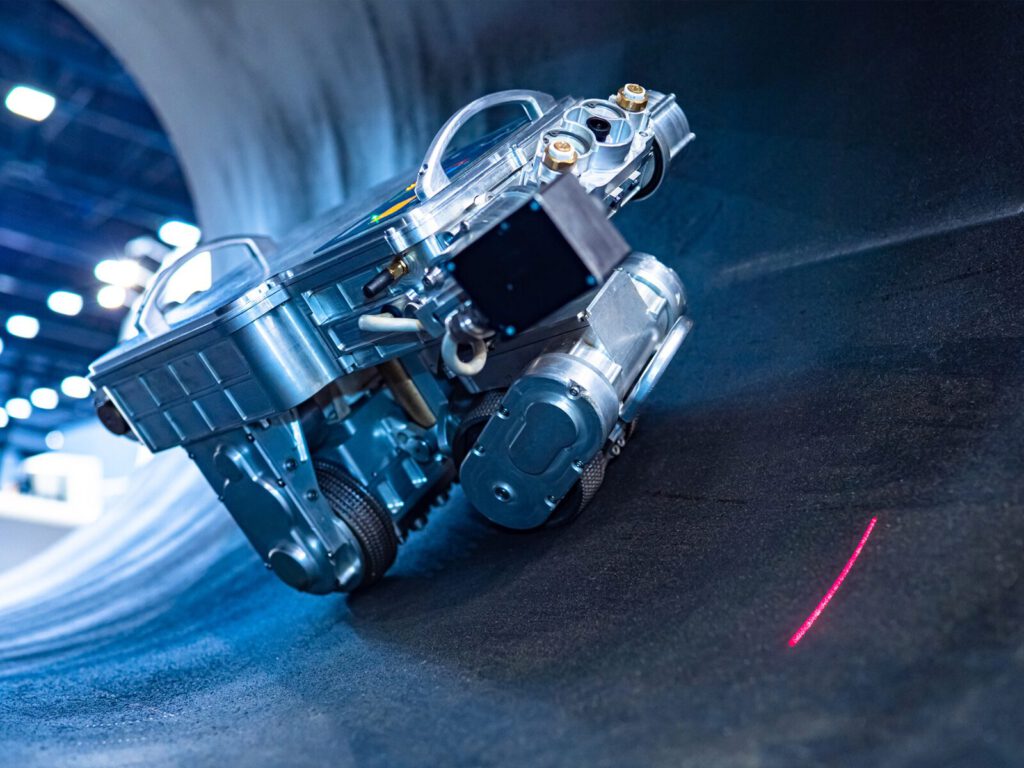

ATS utilizes RVI as an efficient, cost-effective inspection method with a wide variety of applications. We use push cameras, magnetic crawlers, borescopes, drones, and pipe crawlers to address all our clients’ inspection needs. Our technology helps assess flaws such as mechanical damage, corrosion, cracks, and pitting through high-resolution visuals and 3D scanning capabilities. Our certified technicians can collect and analyze data with high accuracy and detail, determining whether repairs are necessary.

Applications for RVI

RVI is a versatile testing method that can save costs on equipment deconstruction and confined space entry. Foreign object search and retrieval (FOSAR) is a common application for remote visual inspections. When objects or debris become lost in inaccessible areas, they can impact equipment integrity. We can pair our RVI technology with retrieval tools to remove the objects from deep within turbines, pipes, and other equipment. Our remote visual inspection services can also assess the health of a wide range of equipment, including:

- Generators

- Piping Systems

- Furnaces

- Boilers

- Condensers

- Pumps

- Tanks

- Turbines

- Rotating Machinery

- Gearboxes

- HRSGs

- Heat Exchangers

We check all equipment thoroughly for flaws and damage to keep clients’ industrial systems running safely and efficiently. ATS also provides several services for the nuclear industry, offering inspections for:

- Control Rod Drive Mechanisms (CRDM)

- Bare Metal (BMI)

- Bottom Mount Instrumentation

- Reactor Pressure Vessels

Our experienced technicians collect thorough, objective data at a competitive cost.

Leading RVI Services

Since 1967, Applied Technical Services has continually expanded our range of NDT services. As industry leaders, we use advanced technology to provide the best remote visual inspection services available. We prioritize our clients, adhering to stringent customer service policies. Our customer service team connects clients directly with relevant experts who can help with their particular inquiries. We deliver clear, detailed, accurate findings as quickly as possible, and our experts can answer any additional questions throughout the testing process.

If you need remote visual inspection services, contact ATS today. We take a closer look!