- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

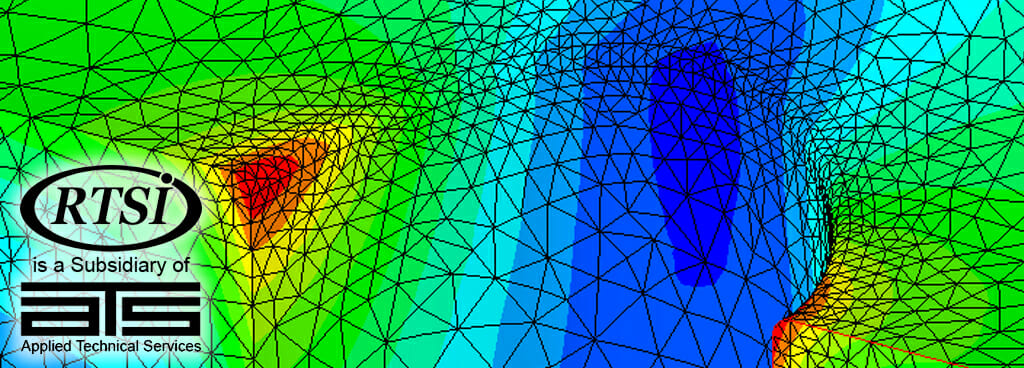

IR Thermography Testing

Thermography testing, also known as thermal imaging or IR thermography, is a nondestructive inspection method that uses infrared radiation to assess equipment health. Every material with a temperature above absolute zero produces infrared radiation (IR), which we feel as heat. Thermographic technology reads the infrared radiation and converts the data into a thermograph: a real-time visual representation of temperature in a given area. At RTS, our state-of-the-art technology can measure temperature differences as little as hundredths of a degree centigrade.

Utilizing Thermographic Testing

Reliability Testing Services uses thermography to benefit numerous industries. During electrical surveys, IR testing allows technicians to check high- and low-voltage equipment for overloading, connection issues, and misbalancing. Additionally, our experts can locate potential or existing failures in heating and electrical systems. We can also conduct skin surveys, inspecting insulation and refractory for damage, as well as other defects in construction for roofing systems and building envelopes. RTS also performs mechanical surveys, searching for signs of overheating equipment, bearing faults, lubrication deficiencies, and problems with pipes, plastics, metal parts, and shafts.

Thermography has several benefits outside of assessing equipment functionality. IR testing can identify humidity, moisture, and water penetration in materials such as soil, paper, and aircraft structures. We can also use thermography to locate objects hidden underground, including storage tanks, pipes and pipe leaks, and tunnels.

Thermographic testing has many advantages that make it a safe and efficient testing method. Thermography is nondestructive, noninvasive, and non-contact, allowing technicians to evaluate equipment without safety risks or disruption to production. This portable testing method does not emit harmful radiation and is suitable for hazardous or inaccessible areas. Thermography produces results in real-time and can evaluate quickly changing thermal patterns.

Choose RTS for Predictive Maintenance

Reliability Testing Services provides expertise in condition monitoring and predictive maintenance. We use advanced technology, including thermography and passive ultrasonics, among others, to help clients optimize their Reliability and Predictive Maintenance programs while minimizing downtime. RTS values our clients’ experience with us, so we implement honesty and integrity in all our services, striving to provide the best Predictive Maintenance services possible. We deliver clear, detailed, actionable information, and our certified experts are available to answer any questions clients may have.

If you could benefit from IR thermography testing, contact RTS today.

Request Form

"*" indicates required fields