- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

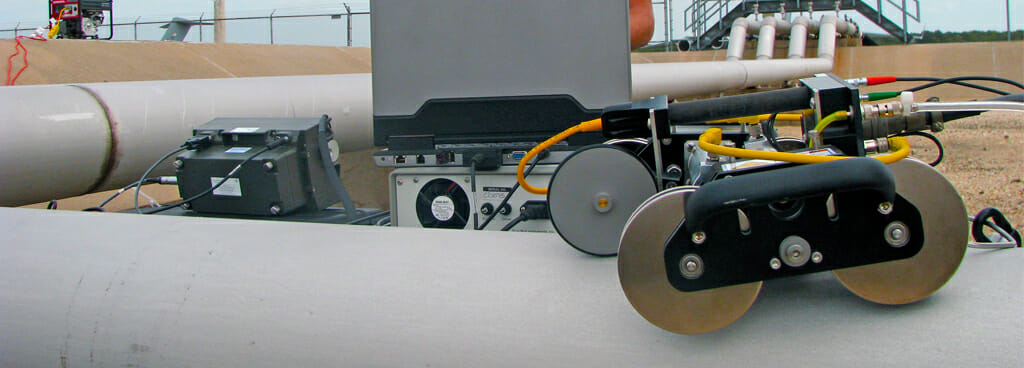

Ultrasonic Pipe Thickness Testing

Applied Technical Services provides ultrasonic pipe thickness testing services to help clients evaluate the condition of their piping systems. Ultrasonic thickness testing (UTT) is a non-destructive method for measuring material thickness from one side of a part or component. Ultrasonic testing utilizes high-frequency sound waves for data collection, allowing inspectors to accurately examine piping without damaging the system. ATS offers UTT for pipes according to the following standards:

- ASME B31.3 – Process Piping

- ASME B31.1 – Power Piping

- API-574 – Piping System Components

- ASME B31.9 – Piping for Building Services

- ASME B31.4 – Pipeline Transportation Systems

- ASME B31.8 – Piping Systems for Gas Distribution/Transmission

- API 570 – In-Service Repair, Inspection, Rating, and Alteration for Piping Systems

This quick, portable testing method allows inspectors to monitor corrosion, erosion, and other damage to piping systems. ATS can use UTT to help clients with all their pipe inspection needs.

UTT Experts

ATS employs trained, licensed, and certified UTT and piping experts to conduct comprehensive condition assessments for client equipment. We can evaluate all our clients’ fixed assets, including pressure vessels, piping systems, tanks, and related parts and components. Ultrasonic thickness testing generates repeatable and highly reliable results and is useful for evaluating large or irregularly shaped components, parts, and structures. Our Professional Engineers and API-certified inspectors collect detailed data that assists proprietors with planning downtime, budgeting for repairs, and planning subsequent inspections. Applied Technical Services is a 3rd party piping and tank consulting company possessing the necessary experience and equipment to assist our clients with all their fixed asset needs.

Routine Pipe Inspection

Following a routine pipe inspection program helps prevent piping system failure, keeping the surrounding environment and nearby personnel safe. Infrequent inspections allow the potential for major flaws to develop, including fractures, corrosion, cracking, erosion, and other defects. Corrosion, in particular, is a leading cause of equipment failure in fixed assets and becomes more dangerous over time.

Applied Technical Services Performs routine system inspection services to prevent equipment failure. Our piping experts can locate potential issues, including corrosion and damaged mechanisms, early. We can evaluate every aspect of your equipment’s condition, from standard compliance to pipe weld quality, to keep your system in proper working order. Our engineers calculate thorough plans for repair contractors that detail the scope of necessary repair work. ATS uses our practical condition assessments to boost our inspection value, minimizing clients’ downtime and prioritizing the needs of their fixed assets.

Mechanical Integrity Services

Applied Technical Services provides more than simple UTT inspections. We offer mechanical integrity programs to assist clients with fixed equipment monitoring and process safety management (PSM). Whether you need UTT pipe testing or an MFL inspection, ATS can assess or design a program that addresses your specific equipment and needs. Our comprehensive mechanical integrity programs cover the following points:

- Inspection frequency and method(s)

- Applicable inspection standards

- Jurisdictional regulations

- Program management/ownership

Our mechanical integrity services apply to equipment such as tanks, pressure vessels, piping systems, and related components. We can locate and identify a wide variety of issues, including flow-accelerated corrosion, manufacturing flaws, fatigue, corrosion under insulation, erosion, corrosion, and cracking, among others.

Pipe thickness testing allows us to deliver detailed documentation and cost-effective services to our clients. Our experts are experienced with various types of equipment, including power piping, also known as high-energy piping. We also provide in-service inspections for clients who need to evaluate essential equipment without disrupting functionality. We have several inspection methods at our disposal that won’t impact system integrity, including penetrant testing, bubble leak testing, radiographic testing, ROV inspections, and magnetic particle testing. Our experts can help determine which of our services best suits your needs.

Excellent Pipe UTT Services

Certified personnel at Applied Technical Services can provide clients with excellent ultrasonic pipe thickness testing services. We have dedicated decades to expanding our capabilities and realm of knowledge while providing excellent customer service. We utilize our mechanical integrity services to serve numerous industries, such as:

- Industrial

- Manufacturing

- Oil and gas

- Construction

- Pharmaceuticals

- Energy

- Chemical

- Government

- Pulp and paper

- Nuclear

- Commercial Properties

- Military

For ATS, safety is a priority, alongside accurate and detailed reporting. We keep clients updated during the inspection process, so they have a thorough understanding of their assets’ status. We offer quick turnarounds, and our experts can answer any questions clients have about testing or data.

If you need ultrasonic pipe thickness testing, contact ATS today.

Request Form

"*" indicates required fields