Failure Analysis Services at ATS

Applied Technical Services offers SEM failure analysis as a dependable method of observing and categorizing a material failure. Companies request failure analysis services from esteemed providers like ATS when their product, component, or material fails prematurely or unpredictably in its service environment. Our failure analysis division uncovers the root cause behind the failure and suggests remediation steps to prevent it from happening again; our clients trust us to do these things because of our expertise and sterling track record in the failure analysis field.

How SEM Applies

Scanning Electron Microscopy, commonly referred to as SEM, produces a vivid image of the sample’s surface magnified anywhere from a few dozen to tens of thousands of times. ATS’ failure analysts use our Hitachi S-3700N scanning electron microscope to take these microscopic images. Our advanced large-chamber instrumentation allows us to accommodate sizeable samples without having to section them, to measure features as small as 0.1µm, to utilize our energy-dispersive X-ray spectroscopy (EDS) unit for elemental identification, and to produce images in stunning resolution for in-depth analysis.

SEM represents an invaluable tool in our failure analysis repertoire because it can help our experts identify and predict failure modes by assessing microscopic features, such as:

- Fracture Characteristics

- Type and Shape of Inclusions

- Chemical Segregation via Elemental Mapping

How the Method Works

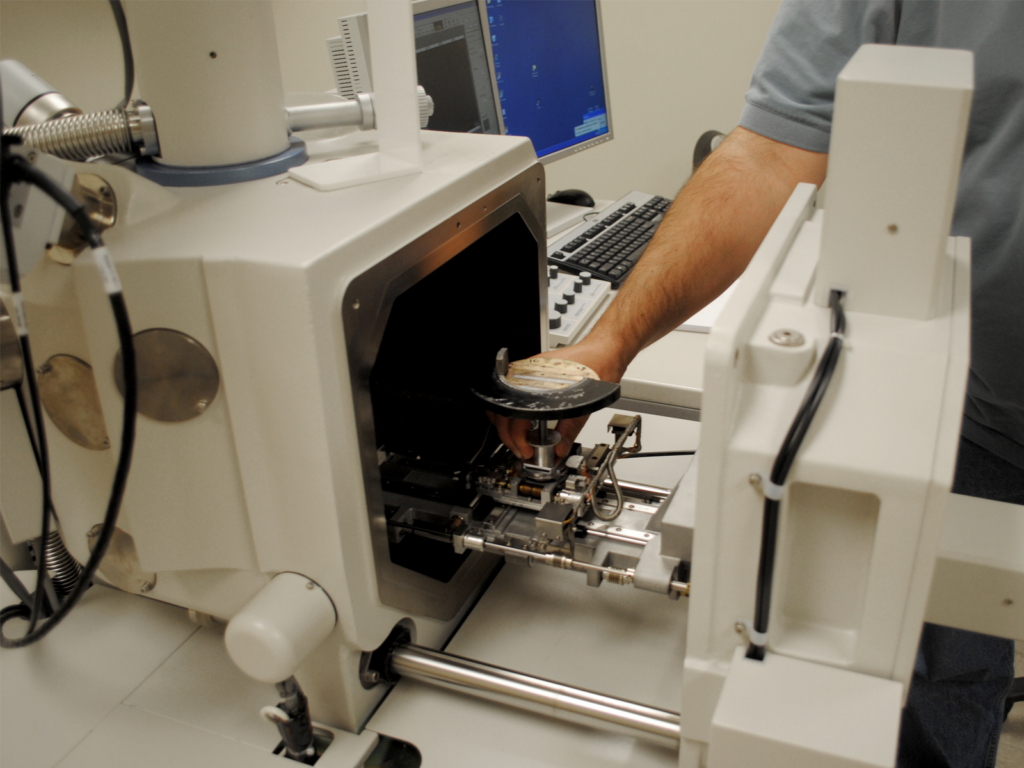

SEM, as its full name implies, makes use of the surface material’s electrons to build its image. The process begins with an analyst introducing the sample to the instrument’s specimen chamber by securing it to the stage. When the chamber is shut and evacuated, they energize the filament that produces primary electrons. Focused through a series of electromagnetic coils onto a small sector of the specimen, the resulting beam of electrons will bounce off the sample’s surface, generating both the secondary and back-scattered electrons used for imaging, along with characteristic x-rays used for chemical analysis.

Frequently Used Standards

Our technicians bring cumulative decades of experience performing failure analysis methods to relevant standards. While these experts can conduct SEM-assisted failure analysis according to client specifications, they execute the method in compliance with the ASTM B748 and ASTM E1508 standards most regularly. The latter specifications fall under the scope of our ISO/IEC 17025:2017 accreditation (maintained through the A2LA).

About ATS

Since our founding in 1967, Applied Technical Services has consistently sought to improve and grow our services. In the 50+ years since then, we have diversified our offerings such that we now provide testing, inspection, consulting engineering, training, and investigation services of the highest caliber. Our multidisciplinary firm attends to the needs of clients operating around the world through the efforts of over 1,000 employees, each a specialist in their field, to deliver a suite of superior services. Nearly every industry can benefit from our failure analysis services when the situation arises.

The following list represents those we work with most often:

- Defense / Military

- Aerospace / Aviation

- Healthcare / Medical

- Pulp & Paper

- Consumer Products

- Automotive

- Insurance / Legal

- Power Generation

- Construction

- Chemical

- Manufacturing

- Oil / Gas

- Communications

- Commercial Properties

- Nuclear

Committed to Quality

Our failure analysis division performs all SEM testing in accordance with our stringent quality assurance program. We have maintained registered status with ISO 9001:2015 uninterrupted since 1998. ATS values this certification because it indicates to clients how seriously we take the matter of providing quality services. In order to achieve and uphold the registered status, we regularly subject our management system to an exacting auditing process carried out by ISO-approved inspectors. They consistently find that our business processes comply with the internationally recognized standard covering effective quality management practices. By closely adhering to the principles outlined in our ISO 9001:2015 registration, our company gave itself a platform from which we have continually improved the range and quality of our services.

ATS built a customer service infrastructure to ensure that our clients enjoy the best experience we can provide. Our testing experts produce clear, accurate, and detailed reporting in a quick turnaround time. They do so to empower clients to make timely and informed decisions because we understand that waiting for weeks to obtain the results of their testing will slow their entire process. Furthermore, clients may reach out to us for clarification. Our customer service team always answers promptly and courteously, facilitating client contact with the personnel most able to help clear up their issue. Finally, our testing specialists remain accessible for customers reaching out with a question regarding either the status or results of their testing. These professionals are responsive to clients’ needs and stay engaged while helping them solve their problems.

Contact Us

If your company needs expert failure analysis services, contact ATS today for a free quote — We take a closer look.