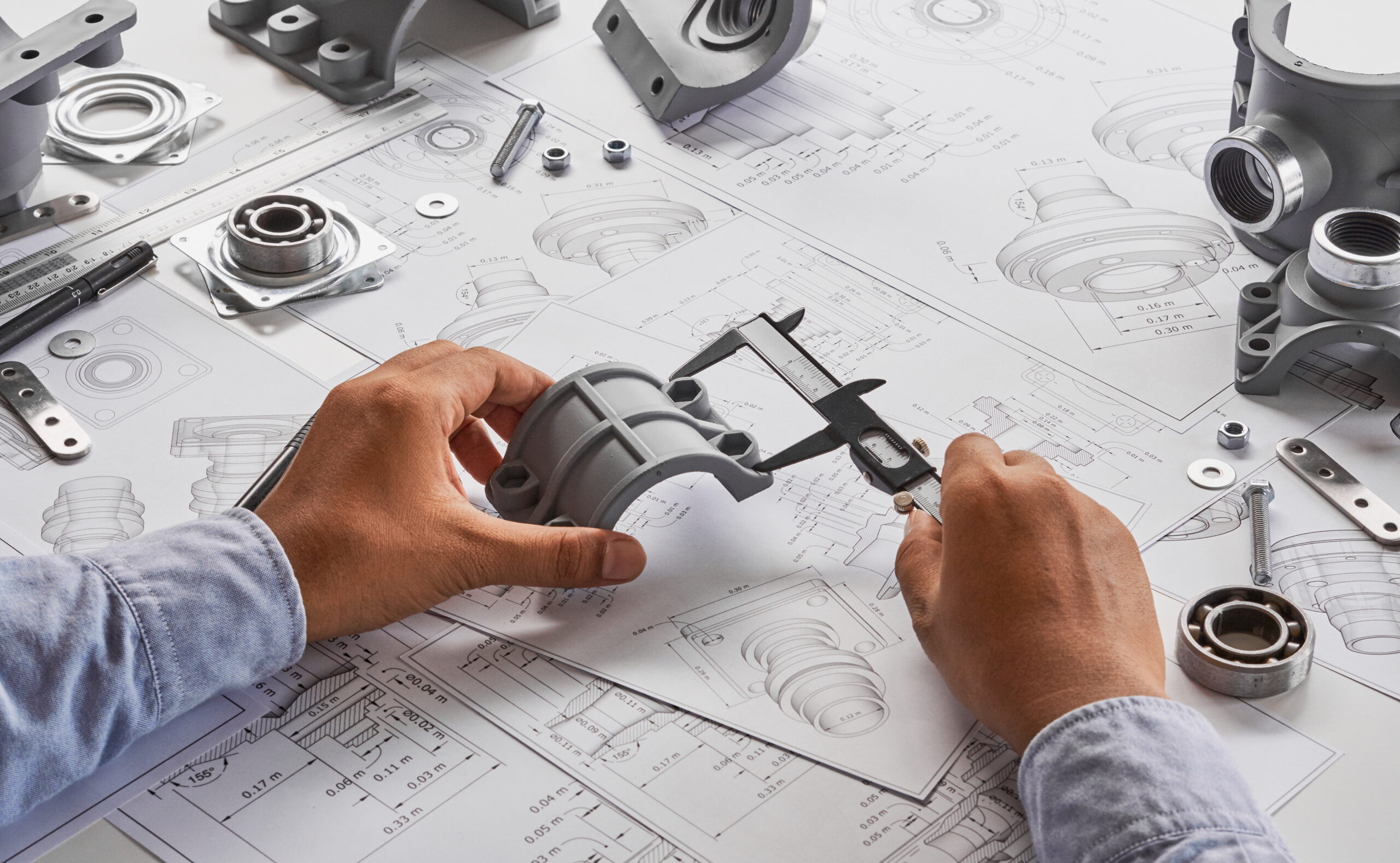

Product Development

ATS can assist with every step of the product development process, from conception through failure analysis. Get the data you need as you need it, whether you’re conducting materials selection or verifying standard compliance. Our experts provide critical insights into safety, reliability, and performance that help guide decision-making.

Consumer Product Testing

ATS consumer product testing plays a critical role in enhancing product development by validating performance, identifying design flaws, optimizing user experience, and ensuring regulatory compliance. Our engineers’ testing procedures uncover potential design flaws, manufacturing defects, or material weaknesses that may impact product performance or user satisfaction. Our inspections validate product claims and marketing messages related to performance, efficiency, durability, and environmental impact. ATS follows all standards, and we are compliant with all industry regulations, allowing product developers to deliver high-quality products that meet customer expectations and achieve market success.

Materials Testing

Materials testing is integral to product development, significantly improving product performance, reliability, and durability. Our engineers assess how products perform under different scenarios and identify potential weaknesses or failure modes. We replicate various environmental conditions that products may encounter during their lifecycle in harsh or challenging environments. We also assess the structural integrity and mechanical properties of materials, components, and assemblies under static, dynamic, or cyclic loads. Our experts ensure that products meet prescribed design criteria, withstand specified loads, and operate safely within intended applications.

Environmental Testing

Our engineers assess how products perform under different scenarios and identify potential weaknesses or failure modes. We utilize testing such as temperature extremes, humidity, vibration, shock, and corrosion to verify product safety, performance metrics, and environmental impact. Our testing mitigates risks early in the development cycle by uncovering vulnerabilities or performance limitations under specific environmental stresses. It informs design modifications, material selection, and manufacturing processes to address potential failure modes and improve product resilience

Electrical Testing

Electrical testing is essential for validating the performance, safety, compliance, and reliability of electrical products and systems during the development lifecycle. Our test methods detect electrical faults, wiring errors, short circuits, open circuits, and other electrical anomalies that could lead to product malfunctions or safety hazards. Early diagnosis can rectify the issue early in the development cycle to prevent costly rework or field failures. Our testing laboratory offers a broad spectrum of electrical and electronic product testing, evaluating the durability, reliability, and long-term performance of the product.

Failure Analysis

ATS Failure Analysis Lab diagnoses failures, improves product reliability, optimizes manufacturing processes, mitigates risks, and fosters innovation in product development. Our testing uncovers the root causes of failures by investigating failed components or prototypes. We examine factors such as manufacturing defects, inadequate materials, improper design specifications, environmental stresses, or operational misuse that contributed to the failure. Insights from failure analysis guide improvements in product design, materials selection, and manufacturing processes.