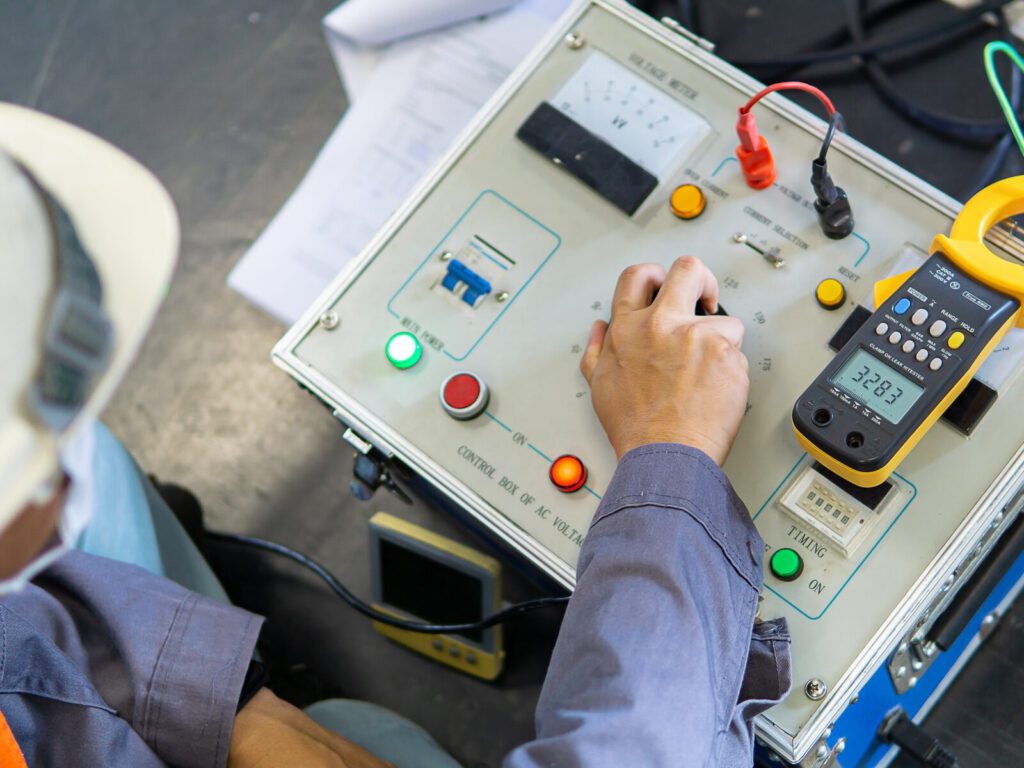

Schedule dielectric breakdown testing from Applied Technical Services (ATS) for a reliable and thorough analysis of insulation materials. Our testing specialists can determine the dielectric breakdown voltage, the point of failure where electricity flows through an insulator as a puncture, electrical arcing, flashover, burn-through, or discharge. Our team of experts performs dielectric testing to identify an insulator’s limits before the material conducts a charge through or along the surface.

Reasons for Dielectric Breakdown Testing

Research and Development

Clients may use a dielectric breakdown test in the research and development process for insulator materials in industrial equipment, personal protective equipment (PPE), and several other applications. This type of electrical testing helps determine how well insulating materials endure electrical stress at commercial power frequencies.

Safety

Dielectric breakdown testing reveals a product’s safety hazards. High-voltage power supplies need reliable insulators to avoid creating safety hazards. Insulators must withstand anticipated voltages, spikes, and transient stresses to prevent damage and injury. Typically, a higher dielectric strength corresponds with a higher quality of insulation. High temperatures, mechanical stress, defects, and contaminant exposure can reduce dielectric strength over time, however.

If a material can no longer resist high voltages, dielectric breakdown begins, which may lead to:

- Electrical arcing

- Electrical shock

- Fire

- Equipment damage

Compliance

Clients may also request dielectric testing to meet electrical safety standards, federal regulations, and state laws, such as OSHA regulations (ex: 29 CFR 1910 and 29 CFR 1926) and the National Electrical Code (NEC) or NFPA 70.

Electrical Testing Applications

Dielectric breakdown testing has many applications:

- Aerospace

- Automotive

- Defense

- Electrical

- Energy Storage

- Manufacturing

- Medical

- Power Generation

- Science

- Telecommunications

What We Do

ATS experts perform dielectric breakdown testing in our ISO/IEC 17025-accredited electrical testing lab. To measure dielectric breakdown voltage, ATS experts apply a current to the sample, steadily increasing the voltage until the sample is destroyed. Our experts thoroughly analyze a material’s dielectric properties and reactions to various voltages to determine its appropriateness for the intended application. We can apply dielectric tests to verify product designs, assess quality after manufacturing, and diagnose the cause of failure in an electrical system.

Our experts study the dielectric properties of plastics and polymers used in items such as:

- Resins

- Rubbers

- Coatings

- Pipes

- Tapes

- Tubing

We can condition and test specimens per client requests and standard procedures. For example, ASTM D149 is a frequently requested dielectric testing procedure that consists of three methods: short-time, step-by-step, and slow rate-of-rise. We test to other official standards from ASTM, ANSI, IEC, IEEE, and MIL-STD.

Other Electrical Testing Services

The Electrical Testing Lab is also capable of the following services:

About ATS

ATS offers a wide range of consulting engineering, testing, inspection, and calibration services for national and international clients. Our Marietta, Georgia headquarters maintains ISO 9001:2015 registration for our Quality Management System and ISO/IEC 17025:2017 accreditations in calibration, electrical, chemical, nondestructive, and mechanical testing disciplines to ensure the quality of our services. Those services additionally comply with federal requirements 10 CFR Part 21 and 10 CFR 50 – Appendix B.

Click here for a complete list of certifications and standards.

Contact Us

Call +1 (888) 287-5227 to speak with a representative about any questions regarding our electrical testing services. Ready to schedule dielectric breakdown testing? Complete the request form on this page or contact ATS today.