Applied Technical Services’ wide selection of capabilities set us apart from the next metallography lab. Not only can our scientists perform metallographic analysis on a range of alloys, polymers, and ceramics, but ATS can also determine sample materials’ numerous mechanical and chemical properties using other branches of testing — all conducted in-house. Our varied body of expertise ensures clients can achieve an array of testing goals through one supplier. Read on to learn about our credentials specific to metallography.

Why Metallography?

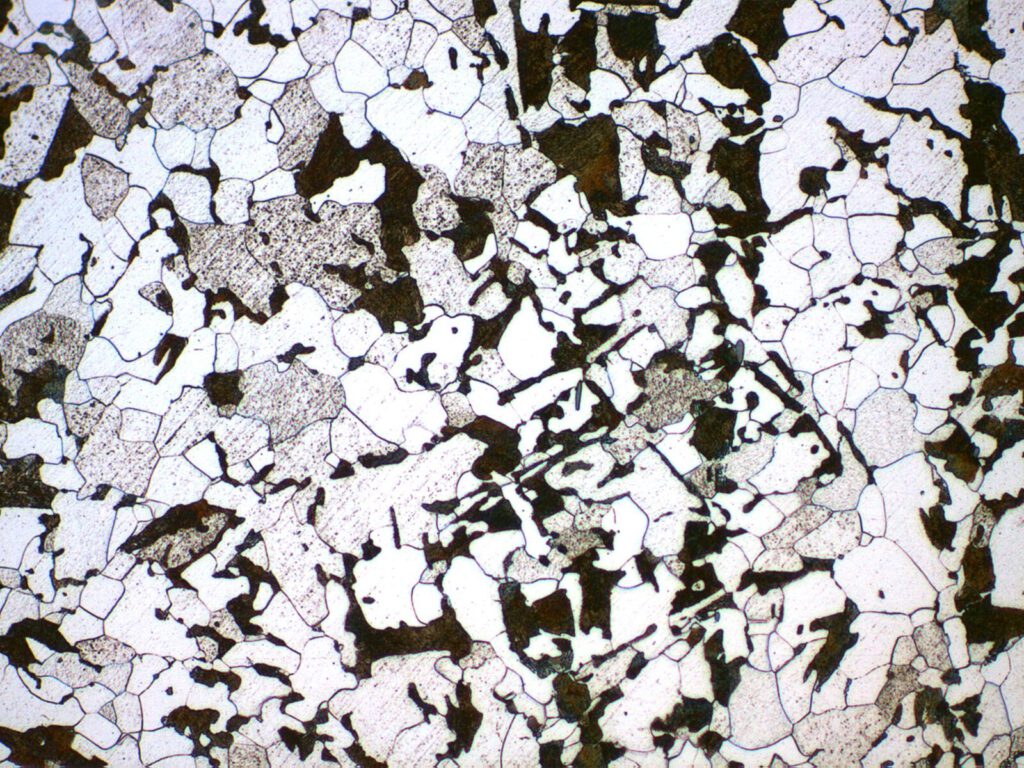

Metallography is the discipline of characterizing the microstructure of samples (often a metal but sometimes a ceramic or polymer material). This type of analysis yields insight into the formation and processing of the material, which can positively or negatively affect the performance of the final assembly in service situations.

The general features of interest include:

- Grain Size

- Grain Flow / Orientation

- Grain Structure

- Phase Identification

- Intergranular Corrosion

- Presence of Nitriding

- Case Depth

- Coating Thickness

- Inclusion Morphology

- Inclusion Content

- Intermetallic Phases

- Porosity

- Void Orientation

Clients may request metallographic analysis for several reasons, such as to qualify a design material or to determine the cause behind a material failure. ATS’ metallography specialists help in this regard by not only performing the methods to confirm the attributes listed above but also analyzing and interpreting the results of their investigation.

The Process

The metallographic process entails a few steps that remain consistent no matter what standards a technician follows. First, our personnel perform sample preparation. This phase includes the following techniques which our technicians use to make microstructural features more easily visible.

- Sectioning: cutting the specimen from the larger material sample. Keeping the specimen small and manageable makes subsequent steps easier. Maintaining the integrity of the specimen requires techniques that do not cause excessive heat that may damage or alter either the resulting specimen or the base material.

- Mounting: improving the handling of the samples and protecting the specimen’s edges. Primarily done by encapsulating the specimen into a compression mounting compound or castable resin.

- Grinding: applying solid abrasives using abrading equipment to remove excess material that makes the specimen’s surface uneven. Capturing an image that adequately highlights the material’s microstructure requires first grinding the surface with a rough grit to flatten the specimen (may include beveling the edges of the mounts to prevent tearing cloths used later in sample preparation) and second with progressively finer grits to remove any scratches caused by previous rounds of grinding.

- Polishing: applying abrasive slurry either by hand using a napless cloth or via polishing equipment. Further smoothing the surface of the specimen requires grits yet finer than can be achieved with a grinding pad. Technicians use lubricants and microscopic diamonds — delivered in a liquid suspension, paste, or even aerosol — to remove damage caused by grinding.

- Etching: applying a chemical solution that produces high contrast between the various features in a microstructure. Technicians commonly use electrolytic, chemical, and thermal etchants (selected as appropriate to the material) to highlight microstructural characteristics in the specimen’s surface.

Our metallurgy lab is outfitted with new, up-to-date sample prep equipment to ensure specimens come out flawless and ready for inspection.

Second, our metallography experts analyze material specimens using either optical microscopy or scanning electron microscopy / energy-dispersive x-ray spectroscopy (SEM/EDS). These methods yield high-definition images plainly displaying microstructural characteristics.

Relevant Standards

Our metallurgy lab regularly performs metallographic analysis in accordance with internationally recognized standards, including ASTM and ISO specifications. ATS’ Marietta Lab maintains an ISO/IEC 17025:2017 accreditation through the A2LA to perform testing to each of the following standards:

- ASTM E3

- ASTM A247

- ASTM E45

- ASTM E112

- ASTM B487

- ASTM B748

- ASTM E1245

This list does not represent all our lab’s capabilities. Clients who require analysis to a standard not enumerated here (or even a custom set of specifications) can nevertheless feel confident contacting ATS for metallography services because of our in-depth experience performing each step of examination according to several standards.

About Applied Technical Services

We pride ourselves in providing expert metallography services performed by specialists with cumulative decades of experience analyzing metal samples. Applied Technical Services has offered these capabilities since 1967. Although ATS began as a cadre of three engineers aiding local companies out of our founder’s basement, we have undergone massive growth in the 50+ years since our founding. We now number over 1,000 — a community of scientists and chemists, technicians and inspectors, Professional Engineers and investigators, calibrators and trainers — and serve clients operating in countries located across the globe.

Of the dozens we serve, the following industries most benefit from our proficiency in metallographic analysis:

- Aerospace

- Chemical

- Foundries

- Insurance / Legal

- Manufacturing (Conventional)

- Nuclear

- Automotive

- Defense

- Oil and Gas

- Manufacturing (Additive)

Our Dedication to Quality

ATS values quality as a central tenet of our business philosophy. To ensure that we uphold the ideal of providing exemplary testing services, we abide by our stringent quality assurance program. The Marietta Lab’s quality management system is registered to ISO 9001:2015. To achieve this merit, we comply with internationally recognized quality management practices, have built a culture of accountability for the caliber of work we perform, and continually strive to improve the customer experience while working with our company. The ATS metallurgy lab performs all metallography analysis in compliance with this program.

If your company needs the services of an expert metallography lab, look no further than ATS. Contact us today for a free quote. We take a closer look!