- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Industrial 3D Scanning

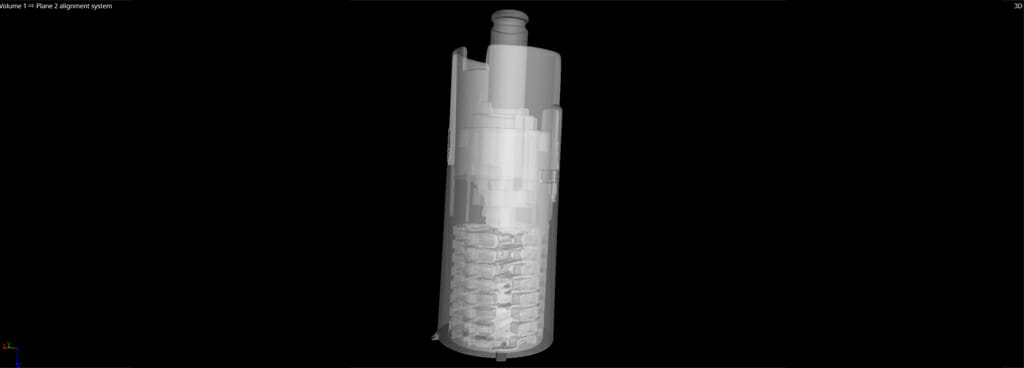

Industrial 3D Scanning allows testing providers like Applied Technical Services to achieve results yielded by several nondestructive testing methods and a full dimensional inspection by completing a single scan. Detecting issues early on and preventive maintenance help prevent major unexpected expenses and loss of production. Industrial 3D scanning uses the same technology as medical-grade CT scanning equipment. It generates a three-dimensional set of data points corresponding to the object being scanned, allowing our technicians to check for flaws or other issues without destroying the item. Our clients can think of computed tomography for industrial applications like a non-invasive CT scan designed to examine a component’s overall condition.

Advantages to CT as a Scanning Method

As a result of recent improvements and interest in industrial 3D scanning, the financial expense to perform CT testing services on equipment, components, and/or products has reduced, making this technology commercially viable as an analysis method.

Nondestructive Testing

Flaw Detection

Allows technicians to discover flaws and other potential problems during a comprehensive industrial 3D scan before such problems can cause damage or halt production overall. This process involves scanning objects to generate a spatial 3D set of data points of an article’s internal components that our technicians can analyze without destroying the sample or becoming otherwise invasive.

Thickness Measurement

Industrial 3D scanning of objects can determine the material thickness and structural integrity of sample materials. This technological advancement allows technicians to measure both the coating and surface material thickness of scanned articles without having to perform an ultrasonic thickness test (UTT).

Dimensional Inspection

- Geometric Dimensioning and Tolerance

- CAD-to-Spec Comparisons

Engineering

Testing Capabilities

ATS utilizes an expansive range of equipment to conduct tests that provide an extraordinary amount of detail with more clarity than conventional radiographic methods. ATS’ CT technicians maintain extensive knowledge and experience while remaining committed to service and integrity, and providing our clients with unmatched data on their scanned articles.

ATS' CT Scanning Technology

Our technologically advanced equipment allows us to produce the high-resolution images and models that make industrial 3D scanning such a desirable method.

- Northstar Imaging X5000

- Multi Axis Manipulator (x, z, tilt, rotation), able to support up to 250 lb

- Resolution of manipulator angle is 0.001 of a degree

- CT System scans with spiral acquisition in order to scan elongated objects that cannot fit within a single standard exposure

- Minifocus 450kV X-ray emitter (0.016” Focal spot at 3mA)

- 0.016” Focal spot at 3mA

- Dual energy capability with 225kV Microfocus X-ray Machine (As low as 0.0002” Focal size based on voltage)

- Zeiss Metrotom 1500

- 225kV micro-focus

- 50 kg (110 lb) weight limit

- Analysis volume up to 300 mm (11.75 in) diameter x 600 mm (23.6 in) high

Request Form

"*" indicates required fields