- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Passive Ultrasonics

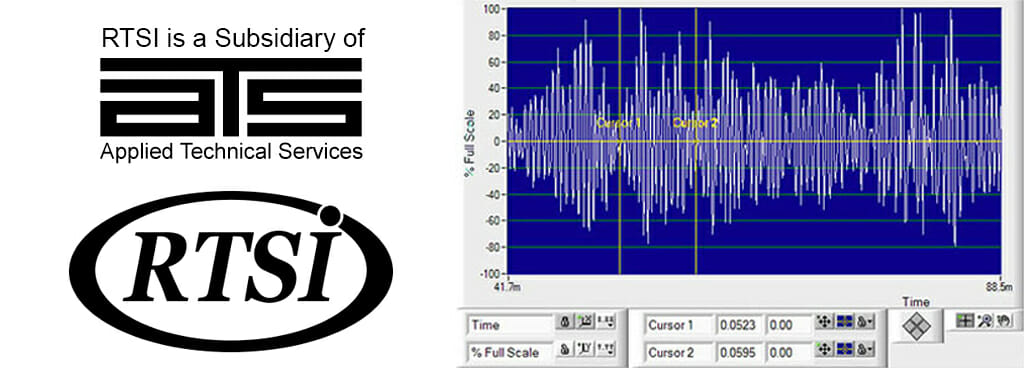

Passive ultrasonic listening detects high-frequency sound waves above the range of human hearing to conduct electrical and mechanical inspections. This non-contact, non-destructive form of inspection locates specific sounds, even in areas with considerable ambient noise. Our experts at ATS analyze the resulting waveform for any irregularities indicative of potential faults. Ultrasonic listening assesses on-line equipment, often before vibration analysis is a viable diagnostic option. This method’s detection speed and ease-of-use on the shop floor make it a versatile option for equipment evaluation.

Passive ultrasonics can supplement infrared thermography (IR) in potentially hazardous situations, especially in medium- or high-voltage enclosures. Our ultrasonic inspections benefit clients in both long-term, result trending applications, as well as short-term troubleshooting. Our knowledgeable technicians operate ultrasonic technology to our clients’ greatest benefit.

Detecting Electrical and Mechanical Faults

Passive ultrasonics can identify several types of mechanical problems. Friction between moving components, such as couplings or gear mesh, creates ultrasonic waves. Ultrasonic listening picks up these wavelengths, allowing technicians to identify flaws such as bearing anomalies, steam traps, and flow issues. This technology can also identify leaks in pressurized or vacuum vessels by detecting the turbulent flow of the gas or liquid from the pressurized to the depressurized environment. Detecting large and small leaks saves clients from costly energy expenses.

Ultrasonic technology also benefits electric condition monitoring practices by detecting events before flashover (arc flash) incidents occur. Ultrasonic listening can also locate most electrical anomalies, such as arcing, tracking, and corona. Passive ultrasonics consistently finds corona and tracking in circumstances where IR usually cannot. This technique even detects electrical anomalies in enclosed cabinets, whereas IR generally will not without access to a port.

Reliability Testing

Reliability testing utilizes predictive technologies to assess the condition of client machinery. Reliability Testing Services applies multiple technologies, such as ultrasonic listening, to our clients’ machinery for a real-time understanding of equipment health. RTS services include:

- Infrared Thermography

- Vibration Analysis

- Motor Circuit Evaluation

- Training Services

- Balancing and Alignment

- Passive Ultrasonics

We use several testing applications to help clients increase profitability and production opportunity, decrease unscheduled downtime, save on repair costs and parts inventory, and facilitate proactive maintenance.

High-Quality Inspection Services

RTS serves commercial and industrial clients with state-of-the-art technology. Our qualified and experienced technicians deliver accurate data to numerous industries, including:

- Power Generation and Transmission

- Processing

- Petrochemical

- Consumer and Food Products

- Metal

- Chemical

- Medical Facilities

- Manufacturing

- Office Buildings

We report detailed findings within a short time frame. If you have any questions about testing or data, our experts will help resolve any inquiries.

If you could benefit from passive ultrasonic listening, contact ATS today.

Request Form

"*" indicates required fields