- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Computed Tomography Labs and How They Help Product Testing

Applied Technical Services offers our capabilities as a computed tomography lab to help clients in a wide variety of functions from the beginning to the end of the product life cycle. Every product that goes to market is meticulously designed by a product engineer, who maximizes its functionality and aesthetic quality by deciding its precise geometric dimensions and material composition, among numerous other considerations. The realities of the production process can, however, depart from the ideals outlined in these experts’ design specifications to a degree that undermines the final product — for this reason, manufacturers trust in third-party testing providers like ATS to verify that their sample was produced correctly and performs as required.

While this often takes other labs conducting several different test methods, our expertise with industrial computed tomography allows us to dramatically reduce the cost and duration of the testing and analysis process, exceeding the results yielded by many testing methods by capturing and analyzing a single CT scan.

The CT Advantage

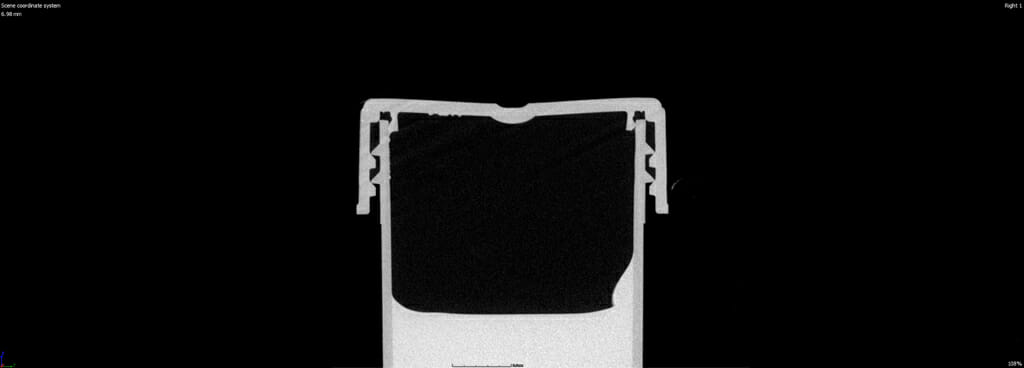

Computed tomography, also referred to as CT, generates a comprehensive image of a product, subassembly, or component by producing a 3D X-rayed model. Because the scan takes thousands of X-ray images of the subject from every conceivable angle — each high-resolution image capturing details at the microscopic scale due to the sensitivity of our instruments — the model our technicians create from collating them into a 3D form allows them to visually assess many of the sample’s characteristics, including:

- Dimensions

- Measure from model

- Both interior and exterior features

- X-ray element allows measurement of material thickness as well

- Not only nondestructive but non-tactile

- Defects

- Detect minute flaws

- Measure them volumetrically

- Categorize them according to size and location

Using these capabilities allows ATS to support clients from an array of industries in several ways, such as:

- Nondestructive Examination

- First Article Inspections

- Reverse Engineering

- Failure Analysis

Because the computed tomography process produces a voxel-based point cloud from which they can derive a CAD file, their work can also aid in reverse engineering applications and simulating stresses using finite element analysis.

About Our CT Capabilities

We pride ourselves in providing models and analysis of excellent quality, each performed in compliance with our ISO 9001:2015 registered quality management program by experienced professionals who bring their best to every scan. ATS sets itself apart from other industrial computed tomography providers by utilizing some of the most advanced technology commercially available outside the medical industry:

- Northstar Imaging X5000

- Multi-Axis Manipulator (x, z, tilt, rotation, pitch, etc.) supports up to 250lb

- Manipulator angle’s resolution is 0.001°

- Can capture elongated samples in a single exposure using spiral acquisition method

- Minifocus 450kV X-ray projector (0.016” Focal spot at 3mA)

- Can achieve focal size as low as 0.0002” (based on voltage)

- Dual-energy capability using 225kV Micro-focus X-ray projector

- Zeiss Metrotom 1500, with a 225kV micro-focus projector

- Undergoes annual A2LA calibration

- Currently certified by A2LA to accuracy within 4.5µm

- Chamber fits specimens up to 11.75 in (300mm) in diameter x 23.6 in (600mm) high; 110lb (50kg) weight limit

ATS — Your Trusted CT Provider

Since our founding in 1967, Applied Technical Services has long prioritized expanding the scope and deepening the extent of our expertise. No longer a trio of engineers constrained to serving local businesses from our founder’s basement, we now perform testing, analysis, inspection, and (of course) consulting engineering on behalf of companies operating the world over. We maintain stringent customer service standards, ensuring clients receive timely results and responses from relevant subject matter experts to promote a positive customer experience.

Components and subassemblies need testing, so why not get it done all in one place? Contact ATS today to see how the South-East’s most reliable industrial computed tomography lab can serve your testing needs — We take a closer look!

Request Form

"*" indicates required fields