- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Reasons for Fracture Toughness Testing

Applied Technical Services performs fracture toughness testing according to ASTM E399 for clients who need to determine one aspect of a material’s suitability for use. Fracture toughness is the quality that describes how well a material resists fracture once it has already developed a fatigue crack. Once such a flaw initiates in a material, it will eventually cause failure due to fracture: the only question is of when. For this reason, fabricators and product designers favor materials that display a greater fracture toughness value in structural applications (i.e. a material that will exhibit ductile fracture), as this degree of resistance can decide the difference between detecting a flaw in its early stages and missing it until the structure suffers complete failure — a potentially costly alternative.

One of the ways ATS helps clients determine this measure of a material’s durability by testing it according to ASTM E399.

How ASTM E399 Works

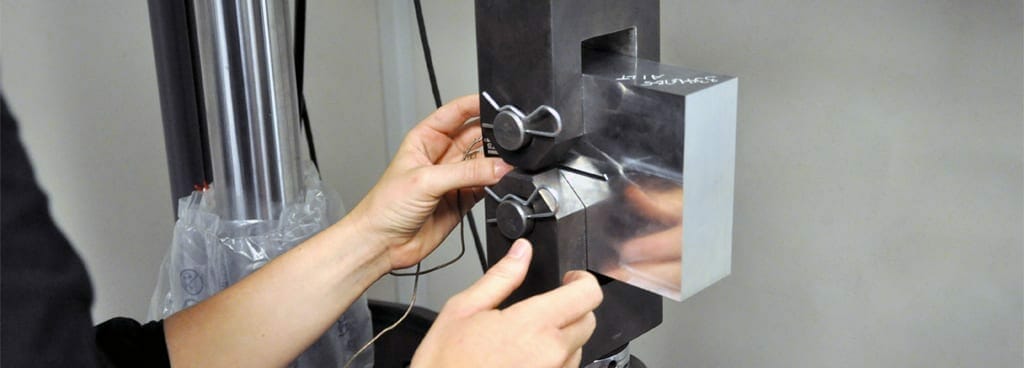

ATS’ Mechanical Testing lab performs this testing method, sometimes referred to by its formal designation of Linear-Elastic Plane-Strain Fracture Toughness Testing. Our certified technicians begin the process by machining a material sample to specified dimensions. Because the method tests a material’s resistance against an existing crack propagating, these experts then introduce a standard fatigue crack into the material’s structure; they account for the location and direction of the crack by notching the sample in its center and dictate the length of the crack by applying a predetermined number of tension-compression cycles at a calculated force. Next, they affix a strain gauge to the opening of the crack to monitor its change over the duration of the test. Finally, they apply either tension-compression or three-point-bending stress to the sample until it fractures.

By assessing the way that the crack propagates through the sample, technicians can learn about the material’s properties. They specifically look out for the threshold at which unstable (brittle) crack growth turns into stable crack growth (also known as tearing). This threshold indicates an event called a “pop-in,” which indicates a transition from a brittle to a ductile fracture and can be useful in finding the material’s crack tip opening displacement. Applying appropriate calculations allows technicians to find the plane-strain fracture toughness, notated as KIC.

The technicians that staff our Mechanical Testing lab boast decades of cumulative experience performing linear plane-strain fracture toughness testing. ATS maintains ISO 17025 accreditation through the A2LA to conduct this method to ASTM E399.

ATS: A Trusted Mechanical Testing Partner

Since 1967, Applied Technical Services has offered testing, inspection, and consulting engineering capabilities of peerless quality. Over the 50+ years since our founding, we have grown from a young engineering firm aiding local businesses from our founder’s basement into a multidisciplinary organization with national presence that employs a team of technicians, metallurgists, scientists, chemists, inspectors, Professional Engineers, and investigators to serve clients stationed around the world. Of the many we serve, the industries that most stand to benefit from our expertise as an ASTM E399 provider include:

- Insurance / Legal

- Defense / Military

- Manufacturing

- Construction

- Nuclear

- Commercial Properties

- Oil / Gas

- Automotive

- Power Generation

- Aerospace / Aircraft

- Renewable Energy

Quality as a Priority

Every one of the mechanical testing services that ATS provides complies with our stringent quality assurance procedures. Our QA department maintains our quality management system’s certification to ISO 9001; this recognition signifies that our program follows the principles outlined in the internationally recognized standard for quality management.

Furthermore, we take several steps to ensure our clients enjoy a positive experience working with ATS. Firstly, our testing personnel return clear, accurate, and detailed results within a short turnaround window so that clients can more quickly make informed decisions. Secondly, when our customer service representatives receive calls from clients with questions regarding the status or results of their testing, they facilitate client contact with relevant testing personnel. Lastly, our technicians remain accessible for clients reaching out with questions, responsive to their needs, and engaged in helping them secure solutions to their problems.

If your company needs fracture toughness testing according to ASTM E399, contact ATS today — We take a closer look!

Request Form

"*" indicates required fields