- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Metallurgical Testing Services

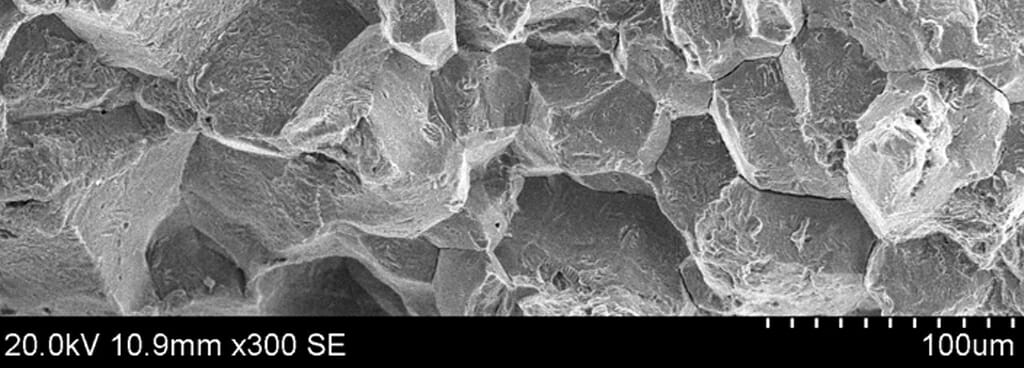

Applied Technical Services routinely performs metallurgical testing services to analyze a variety of metals, ceramics, and composites. Our full range of metallurgical testing services has applications in failure analysis, quality assurance, reverse engineering, and litigation support. We work closely with our clients to fully grasp the extent of their needs. Our metallurgists and technicians abide by recognized testing standards to determine the effects of material composition, manufacturing, processing, size, and shape on the sample’s integrity.

Metallurgical testing can help to both identify the cause of metal failure and inform preventative measures against future failures. ATS’ metallurgical specialists use microstructural analysis to investigate the various effects of manufacturing processes on a material. Their analysis may involve a qualitative examination, quantitative measurements, or both. Microstructural analysis consists of determining a sample’s grain size, grain structure, and grain flow/orientation, measuring its case depth and coating thickness, categorizing its inclusion morphology and inclusion content, establishing the presence of any nitriding, identifying its intermetallic phases, characterizing any porosity, and verifying the void orientation.

Our experienced metallurgists can determine the root cause of the most challenging metallurgical failures. Failure modes common to metal include fatigue, corrosion, brittle fractures, ductile fractures, metal creep, hydrogen embrittlement, and stress corrosion cracking. We provide detailed and conclusive failure analysis reporting to inform our clients of the process — or combination of processes — that contributed to their material failure.

ATS’ metallurgical testing lab performs services for a wide range of industries nationally and globally. Some of the industries that have partnered with ATS include aerospace/aviation, automotive, alternative energy, commercial construction, consumer products, defense/military, manufacturing, medical equipment, nuclear, steel and aluminum, and weld and fabrication industries. ATS’ advanced and highly technical lab delivers accurate findings and analysis across a multitude of testing disciplines. We adhere to quality assurance standards such as ISO 17025 (A2LA), ISO 9001 Quality Management, and Nadcap to meet client satisfaction daily.

Metallurgical Testing Services Experience:

Metallurgical Testing Services Experience:

Metallurgical Testing Services Specifications:

Request Form

"*" indicates required fields