A benzene analysis utilizes headspace gas chromatography and mass spectroscopy testing to identify the presence and concentration of benzene in a substance. Benzene is a highly flammable chemical and a colorless or yellow liquid at room temperature. This compound occurs both naturally and synthetically, being present in volcanoes, wood fires, gasoline, and cigarette smoke. In the U.S., the most common manufacturing applications of benzene include plastics, nylon, rubber, synthetics, and pesticides. Most recently, chemists have detected the presence of benzene in several brands of sunscreen and hand sanitizer.

Is Benzene Dangerous?

Benzene is a known carcinogen that can cause significant damage to humans. Overexposure to benzene can result in cancer, a reduced red blood cell count, anemia, immune system damage, and excessive bleeding. Benzene is dangerous, and thus exposure should be avoided whenever possible. The FDA’s legal limit of benzene is two parts per million (or 0.0002%).

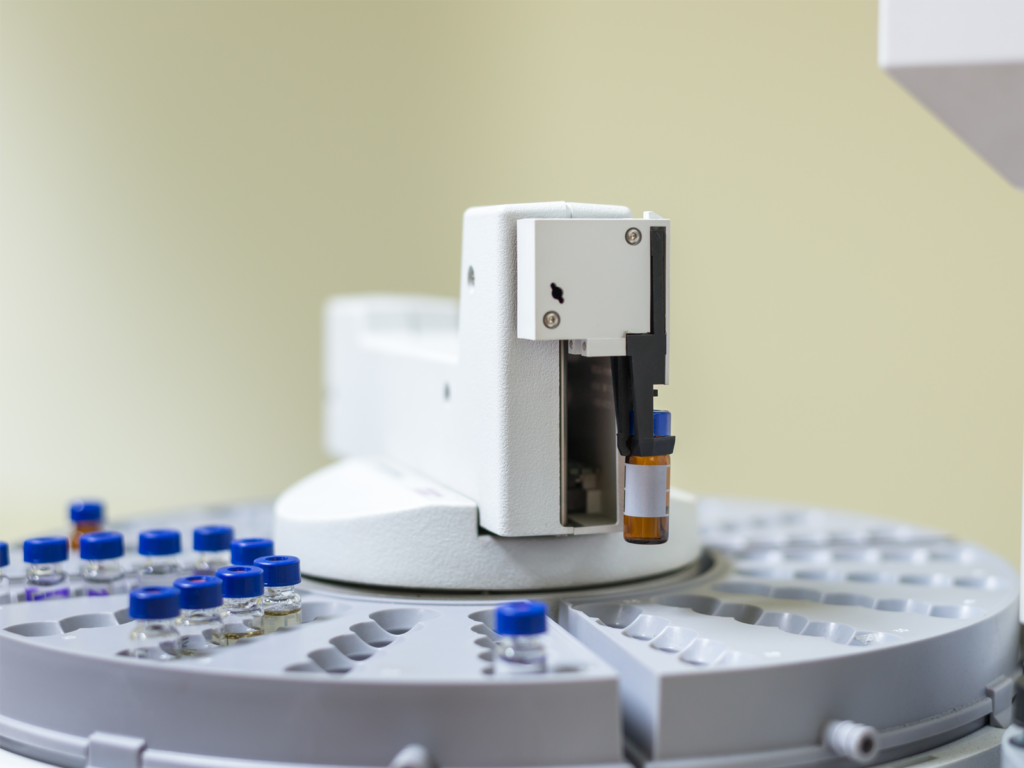

Testing for Benzene Using Headspace GC/MS Analysis

ATS conducts benzene analysis testing using headspace gas chromatography and mass spectroscopy, also known as headspace GC/MS analysis, referencing EPA Method 5021A. Headspace GC/MS analysis is the most prominent testing method for identifying contaminants in products, analyzing volatile compounds, and detecting residual solvents in pharmaceutical products.

The Importance of Benzene Analysis

Valisure has recently created a petition that calls on the FDA to force recalls on all sunscreen products identified to contain benzene. The petition also urges all sunscreen manufacturers to have their products tested for benzene content and recommends new FDA regulations on benzene levels and testing.

Benzene analysis testing is the most effective way to prevent possible recalls of products that may contain benzene and is essential to maintaining brand trust after the recent discovery of benzene in many common sunscreen brands. Benzene product recalls can be financially devastating, costing some manufacturers as much as $250 million per recall.

Applied Technical Services

At ATS, our certified experts and analysts are highly trained, thoroughly experienced professionals committed to providing the highest level of client satisfaction with innovative technologies, reliable information, and excellent customer service. With over fifty years of experience, ATS has the knowledge, skills, and resources to ensure our clients receive the consistent level of high quality testing they need to keep their operations running smoothly and to avoid unexpected downtime and interruptions.

Contact Us

Contact us today to submit your products for benzene analysis testing.