ATS provides blade failure analysis for many companies and industries. Our processes include identifying cracks, fracture modes, and determining the contributions of manufacturing practices and material properties to the failures. Our inspections and testing involve visual inspections, metallography, and scanning electron microscopy (SEM). Additionally, to maintain high standards and integrity of our findings, ATS follows an ISO 9001:2015 registered quality assurance program, providing our customers with a high level of satisfaction.

Why is Failure Analysis Important?

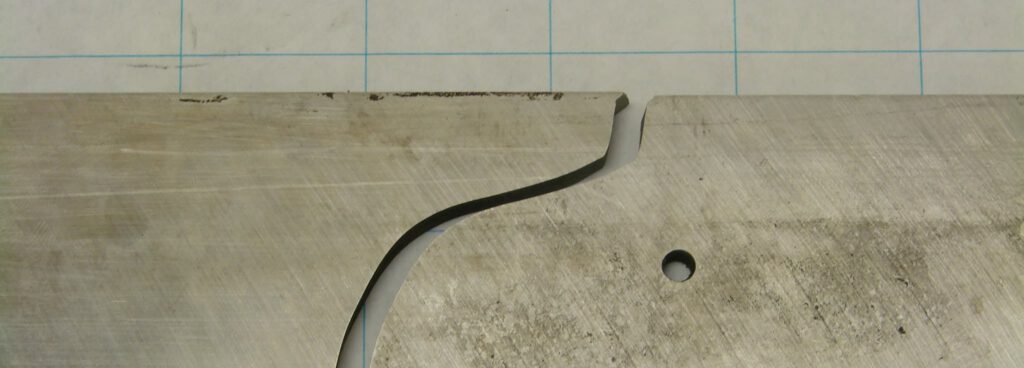

Most blades are utilized in cyclical loading applications, which makes them susceptible to developing fatigue cracks. Therefore, the blade type and heat treat conditions are very important in selecting the proper material for the demanding service environments. Design, manufacturing practices, and the mounting methods of the blade also play a major role since they can contribute to undesirable stress concentrations leading to fatigue crack initiation.

At ATS, we apply the latest state-of-the-art technologies to analyze blade failure analysis. We rely on collecting accurate and appropriate data. Therefore, we approach every test using our systematic procedures to obtain decisive outcomes. By utilizing our complete approach to failure analysis, we are able to produce recommendations in an efficient and cost-effective manner for our clients.

Common Blade Failure Analysis Findings

- Manufacturing Defects

- Fatigue

- Product Design Issues

- Maintenance Issues

- Inadequate Materials

- Improper Heat Treats

- Environmental Effects

- Material Defects

Blade Failure Analysis Types

- Fatigue

- Creep

- Corrosion

- Impact

- Erosion

- Sulfidation

Contact Us

Call +1 (888) 287-5227 or click here to request failure analysis of a blade.