Fillet welding is one of the most commonly used welding methods. To be considered an expert, welders must prove their competence at fillet welding. ATS offers fillet weld break testing for several applications, including welder qualification. Our welding experts provide thorough, accurate insight into a weld’s quality.

Break Testing

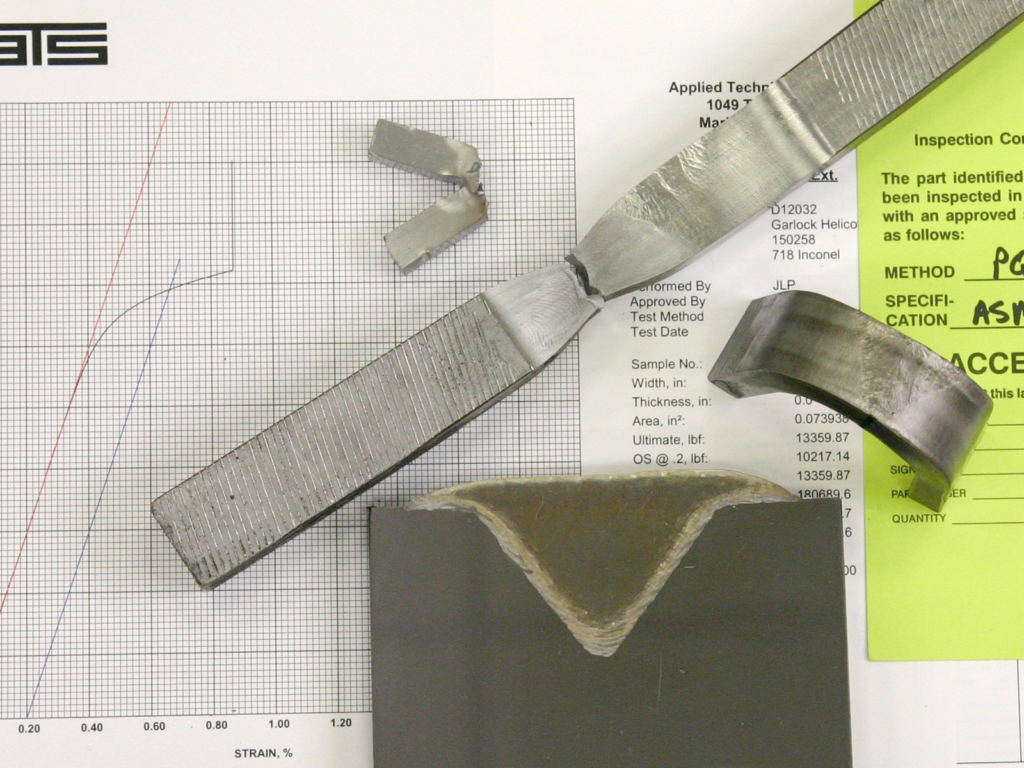

The fillet weld break test is a type of mechanical testing that examines root penetration. This test specifically examines one-sided fillet welded joints. The break test can inspect the entire coupon for discontinuities and flaws, rather than just a sample cut. This includes potential failure points such as the stop and restart.

To conduct a fillet weld break test, a technician loads the unwelded side of the coupon until it bends flat upon itself or fractures. If fracturing occurs, the weld cannot show any evidence of cracks or incomplete fusion in order to pass. The break test can also reveal other internal issues, such as incomplete penetration, porosity, and slag inclusions.

Macro etch testing often accompanies the break test for a more comprehensive evaluation.

Our Weld Analysis Expertise

Applied Technical Services has decades of experience in weld inspections, testing, and certification. We employ an experienced team of certified weld inspectors, professional engineers, certified welders, metallurgists, certified technicians, API inspectors, chemists, and scientists to perform weld inspections.

Our experts regularly inspect bridges, piping, pressure vessels, and other components. We also provide proof and documentation of a welder’s competency level, using mechanical tests to examine their work.

Along with fillet weld break test, we perform several types of mechanical weld testing, including:

- Load Testing

- Lap Shear

- Hardness Testing

- Charpy Impact Testing

- Bend Testing

- Micro Hardness Testing

- Drop Weight

- Tensile Testing

Nondestructive Weld Inspections

We also offer several nondestructive weld inspection methods for the detection of surface and subsurface flaws, such as:

- Traditional Radiography Testing (RT)

- Visual Testing (VT)

- Magnetic Particle Testing (MT)

- Computed Digital Radiography (CDR)

- Liquid Penetrant Testing (PT)

- Ultrasonic Testing (UT)

ATS Weld Inspection Services

For decades, Applied Technical Services has provided high-quality weld testing and inspection services. We have built an excellent reputation in several industries, including:

- Manufacturing

- Construction

- Offshore Drilling

- Aircraft

- Maritime

- Automotive

- Power Generation

- Petrochemical

Our staff is highly responsive to all our clients’ needs. Our customer service team always connects clients with attentive, relevant experts. We report accurate, detailed data as quickly as possible.

If you have any questions regarding testing or results, our team of experts can help resolve your inquiry. If you need fillet weld break testing, contact ATS today.