ATS offers load testing for companies needing to determine load carrying capabilities of equipment, components, parts, and structures. On a regular basis, our qualified and equipped experts monitor how test samples react to static, dynamic, and cyclical mechanical loads. There are many industry standards that provide detailed procedures that assist in determining if a product’s properties are fit for service.

Load Testing Determinations

- Safe Working Load — Manufacturer’s recommended maximum load

- Yield Load — When a material shows signs of stress and degradation

- Failure Load — Complete material and/or mechanical failure

Mechanical Load Methods

- Static Testing — When a product is exposed to a constant load for a specified time. This method applies tension at a uniform and slow rate.

- Dynamic Testing — When a component is exposed to a moving load. This method imparts tension load rapidly by increasing the speed or by applying sudden spikes of stress.

- Cyclic Testing — When materials are subjected to a loading and unloading force for specified conditions, cycles, and durations. Defined stresses may include varying load levels while exposed to drastic temperature changes.

Types of Mechanical Load Testing

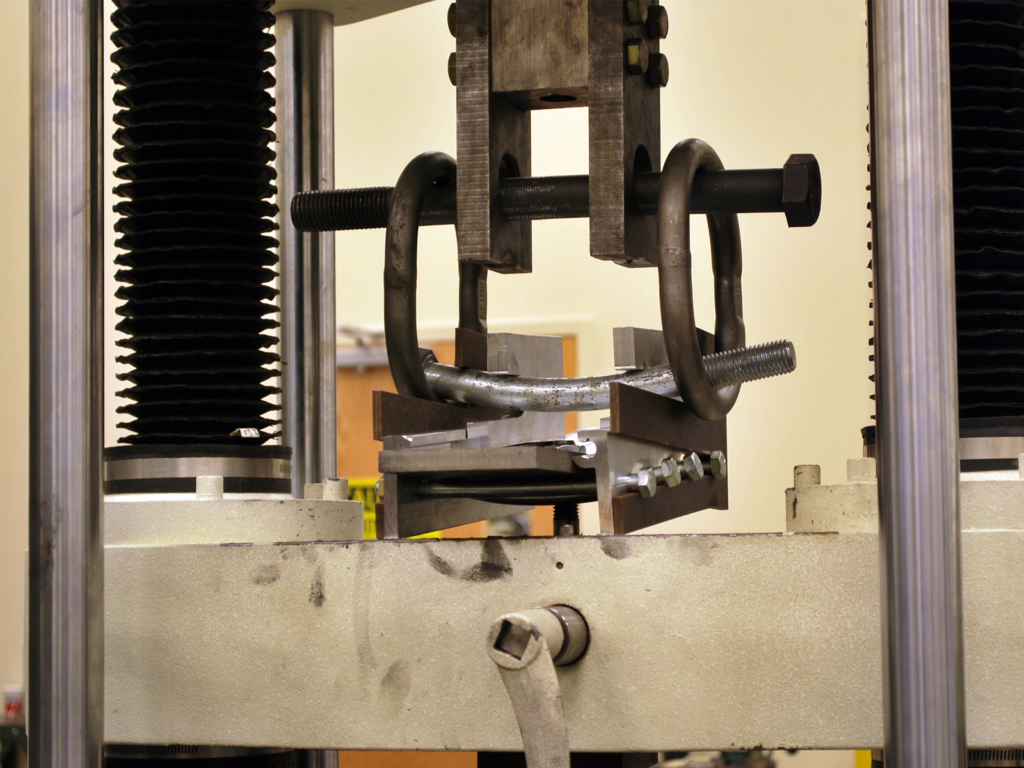

- Tensile Tests — When a sample is subject to controlled tension until failure. It measures tensile strength along with maximum elongation and reduction in area.

- Compression Tests — When a sample is subjected to a compressive force to determine the material’s crush resistance during a defined time period.

- Shear Tests — Determines the maximum shear stress a component can handle before a sliding failure occurs on the plane of an object that is perpendicular to the direction of force.

- Bending Tests — This process measures the ductility(elasticity) and strength of a material. Once the bend is completed to the desired angle the product is inspected for cracks on the outer surface.

- Fatigue Tests — A method used to measure a material’s behavior under fluctuating stresses or strains. This cyclic series of tests simulate working conditions where materials or components undergo cyclic forces.

- Facture Toughness — The ability of a material to withstand static propagation of a fatigue under know loading conditions

- Impact Testing — The ability of a material to absorb energy at high strain rates.

- Bond Strength Tests — This process determines the stress/load required to cause an adhesive bond rupture between two materials. This test can easily be performed in the field or lab environment.

- Proof Tests — When a structure or component is required to demonstrate that it’s capable of bearing a specific safe working load.

The Following Governing Agencies Offer Load Testing Standards and Specifications:

- ANSI — American National Standards Institutes

- ASME — American Society of Mechanical Engineers

- ASTM — American Society for Testing and Materials

- EN — European Standards

- ISO — International Organization for Standardization

- JIS — Japanese Industrial Standards

- Mil-STD — Military Standards

- OSHA — Occupational Safety and Health Administration

- SAE — Society of Automotive Engineers

Reasons to Make ATS Your Mechanical Testing Provider

- Customer Service — Our engaging professionals provide high quality testing services with clear and accurate data in a timely basis.

- Technical Experts — ATS employs motivated professionals who safely deliver quality testing services. Our experts range from licensed professional engineers in various disciplines, scientists, metallurgists, chemists, to well-trained technicians.

- Labs — Our mechanical testing labs are ISO/IEC 17025:2017 accredited according to the A2LA evaluation process and have been awarded Nadcap accreditation by the Nadcap Management Council.

- Quality Assurance Standards — ATS meets the following quality standards: ISO/IEC 17025:2017 accreditation, ISO 9001:2015 registered, 10 CFR 50 Appendix B, 10 CFR Part 21, and ASME NQA-1.