- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

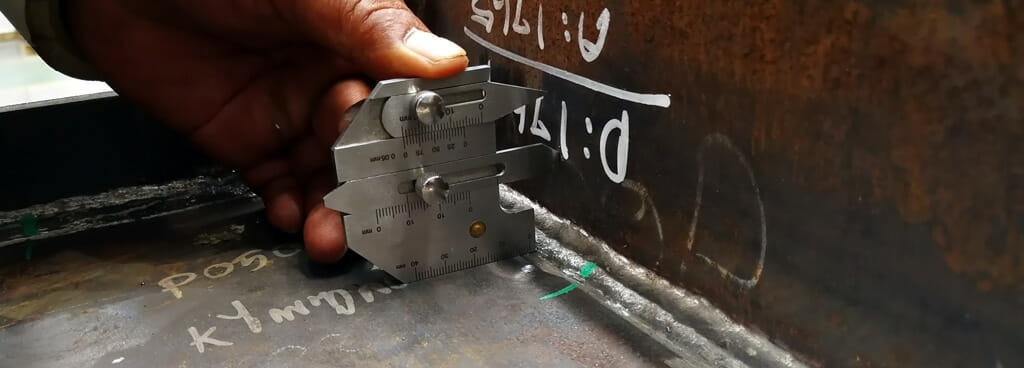

2F Weld Test

ATS understands how significant and daunting a 2F weld test can be for welders. We seek to relieve prospective welders of some of the pressures involved in the certification process by opening our welding facilities for certification and quality testing.

Relatively new welders may opt to work in the horizontal position to lay a fillet weld. The popular 2F position gives the welder a full view of the weld area throughout the welding and cleaning processes. If certified to work in the 2F position, a welder automatically qualifies for work in the 1G and 1F positions, too. However, welders must prove they can navigate the challenges of fillet welding:

- Making the weld consistent and strong

- If permitted, applying enough passes to deposit a weld for thicker material

- Forming a tight arc to minimize spatter and decrease undercutting

Reserve a Welding Booth

Welders have two main avenues for getting certification: through a licensed American Welding Society (AWS) testing facility or an employer. During the hiring process, a fabrication company may request a demonstration of an applicant’s abilities, especially if the potential hire does not have a current certification from a recognized licensing body. Clients can reserve an observation booth at an ATS facility that allows a welder room to work comfortably and safely. Our booths provide the ideal overhead lighting and protection for clients who wish to observe a welder’s technique.

Welders will have access to the equipment for popular welding methods, such as GMAW/MIG, GTAW/TIG, FCAW, and SMAW/stick. In addition, welders can purchase a weld coupon, such as a pipe or plate, from our stock of popular materials.

Schedule a Certified Weld Inspector

ATS offers more than just a venue for weld certification but also the services of our experts with decades of combined training and experience. Our welding staff includes AWS-certified weld inspectors (CWIs) who can recommend certification based on observations and test results.

A CWI can observe the welder throughout the entire process:

- Booth setup

- Equipment calibration

- Welding technique

- Proper positioning

- Adherence to safety protocols

Submit a Weld Coupon for Testing

After the weld is complete, the welded pieces are divided into segments to test for defects, such as cracks, pitting, slag, and spatter, that may disqualify a weld for certification. Fillet welds are prone to issues related to weld size, such as overlap, undercutting, and a lack of fusion. However, some defects may require a more thorough approach.

The ATS weld testing lab is A2LA-accredited to perform mechanical and nondestructive tests. Our qualified chemists and metallurgists can subject coupons to a battery of nondestructive and destructive inspections and evaluations.

Different certification bodies recommend various tests to uncover the limits of a weld coupon, such as bend, tensile, hardness, and corrosion testing. ATS can verify if a weld meets standards set by organizations such as AWS, ASME, ISO, and EN. We also offer a variety of inspections that leave the testing coupon intact, such as liquid penetrant testing and radiography.

Get to Know ATS

Founded in 1967, ATS began as a start-up led by three engineers. Our humble beginnings instilled in us an appreciation for individuals who work toward continual improvement. We encourage our staff of engineers, technicians, chemists, and inspectors to expand their skills through training and ongoing education. Additionally, our organization meets quality standards:

- ISO/IEC 17025 – Competence of Testing and Calibrations Labs

- ISO 9001:2015 – Quality Management Systems

- 10 CFR Appendix B – Quality Assurance Criteria for Nuclear Facilities

- 10 CFR Part 21 – Reporting Noncompliance and Defects

In addition to our A2LA accreditations in mechanical and nondestructive testing, ATS labs also hold accreditations in:

- A2LA – Chemistry Testing

- A2LA – Calibrations

- A2LA – Electrical Testing

- NADCAP – Nondestructive Testing

- NADCAP – Materials Testing

Contact Us

Call +1 (888) 287-5227 or complete the request form on this page to schedule a 2F weld test observed by a qualified CWI today. If a welder achieves 2F certification, they can prepare for additional training and return for certification testing in a more complicated position:

Learn more about our welding services.

Request Form

"*" indicates required fields

Weld Testing Links

- 1G Weld Test

- 2F Weld Test

- 2G Weld Testing

- 3G MIG Welding Test

- 4G Welding Certification

- 6G Welding Certification

- ASME Sect IX Testing

- AWS D1.1 Testing

- AWS D1.2 Testing

- AWS D17.1 Testing

- Certified Welding Inspectors

- Cut and Etch Weld Testing

- Destructive Weld Testing

- Fillet Weld Break Testing

- Fillet Weld Fracture Test

- Fillet Weld Test

- Fillet Weld Testing

- Macro Etch Testing

- Macro Etch Weld Test

- Macro Etch Weld Testing

- Pipeline Inspection Companies

- Pipe Weld Testing

- SMAW Welding Certification

- Spot Weld Testing

- Structural Steel Welding Certification

- Stick Welding Certification

- Visual Weld Testing

- Weld Engineering Company

- Weld Analysis

- Weld Bend Testing

- Weld Break Testing

- Weld Hardness Testing

- Weld Inspections

- Weld Inspections Services

- Weld Joint Testing

- Weld Notch Toughness Testing

- Weld Procedure Qualifications

- Weld Tensile Testing

- Weld Testing

- Weld Testing Services

- Weld Qualification Testing

- Welder Certification

- Welder Qualification

- Welding Certification

- Welding Certification Test

- Welding Engineering

- Welding Inspector

- Welding Test Coupon

- Welding Testing Lab

- Weld Testing Services

- WPS Qualified Welding Procedure

- WPS Welder Qualifications